Installation, Manual release, Torque adjustment – Dings Dynamics Group 80 Series End Mount NEMA 4 HEAVY DUTY User Manual

Page 2: Wear adjustment, Friction disc replacement, Manual release assembly, Magnet coil replacement

INSTALLATION

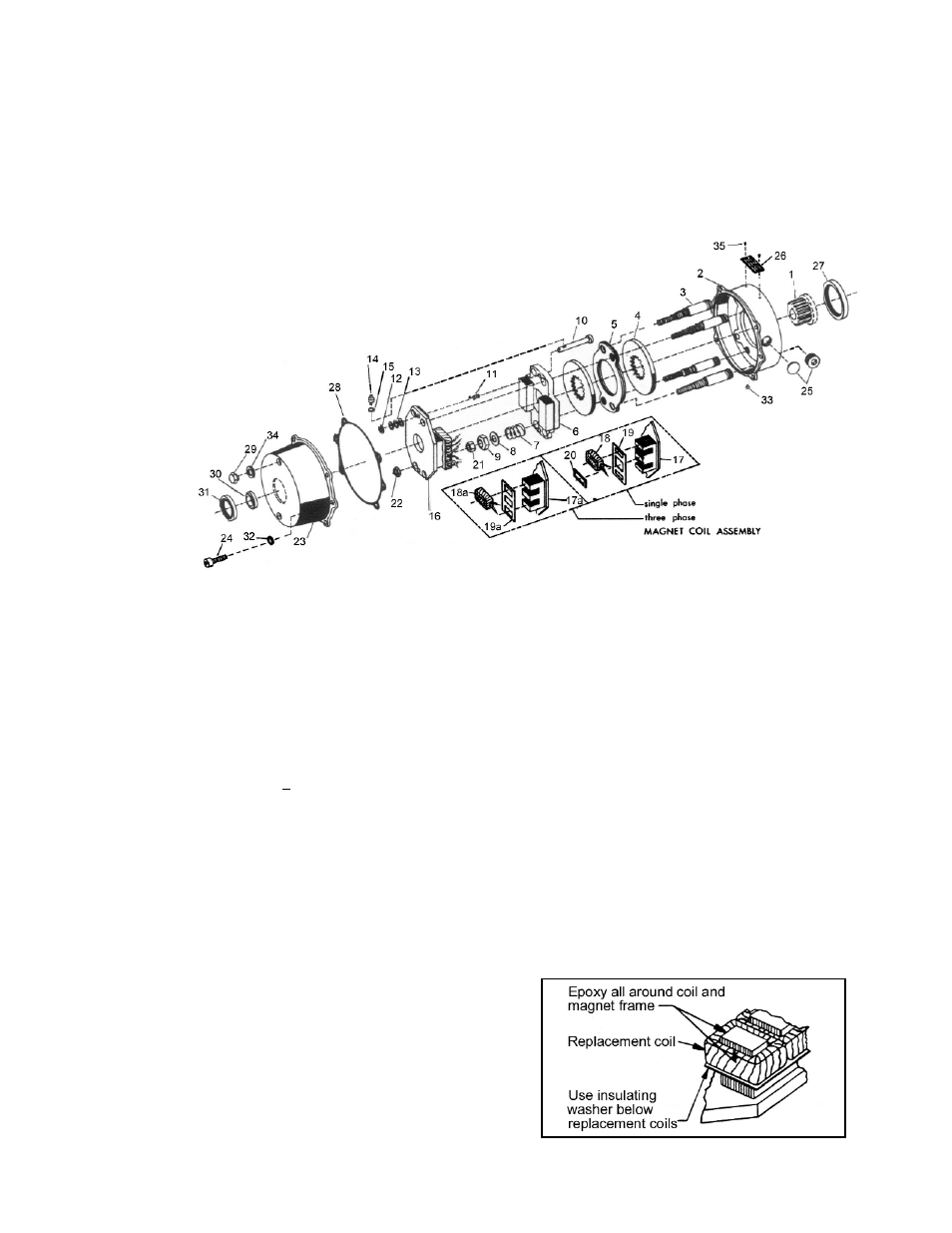

(See Figures 3 & 5, Tables 1 & 2)

1. Remove hub (1) from brake and position on motor shaft with key

according to dimension “N”. Stamped part number on hub should

face away from motor. Tighten hub set screws with 12 lb. ft. torque.

2. Remove cover screws (24) , cover (23) and gasket (28).

3. Place brake on motor, guiding discs on hub.

4. Bolt brake to motor “C” face with four 1/2 inch socket head cap

screws. See Figures 5 and 6 for screw length thru bracket.

5. Connect coil leads per appropriate wiring diagram in Figure 2 and

replace cover.

MANUAL RELEASE

(See Figure 3)

To operate release, rotate two rods(10) clockwise until stop screw

(14) hits pin. Release cap (29) must be removed by unscrewing,

before rods can be rotated.Brake will remain in released position until

rods are manually returned to original position, or until electrical power

is restored which automatically returns the release rods to the set

position.

TORQUE ADJUSTMENT

(See Figures 3 & 5)

Brake is factory set for rated torque per spring length “H”. To increase

stopping time and lower torque, turn four locknuts (9) counterclockwise,

increasing dimension “H”. All four springs must be set to the same

length. Do not decrease spring length “H” as this may cause coil to

burn out.

WEAR ADJUSTMENT

(See Figures 3 & 5, Table 2)

Magnet gap “D” increases as friction discs wear. When gap approaches

“D” max., adjust gap to “D” min. dimension by turning nuts (21 and 22).

Magnet gap can vary from nominal + .005” between corners. After

setting gap, readjust torque spring length “H”.

CAUTION: MAGNET GAP MUST NOT EXCEED

“D” MAXIMUM.

FRICTION DISC REPLACEMENT

(See Figures 3 & 5, Table 2)

*When the rotating friction disc (4) wears down to a thickness of 7/32”,

replace disc.

1. Remove cover screws (24), cover (23) and gaskets (28 & 32).

2. Unhook loop of torsion springs (11) from pins at rear of magnet

plate (16). Remove release stop screws (14), washers (12) and

shims (13).

3. Remove adjusting lock nuts (22), magnet assembly (16), adjusting

nuts (21), torque nuts (9), washers (8), torque spring (7) and

pressure plate (6).

4. Remove friction disc (4) and stationary disc (5). Replace worn

friction discs.

5. Reassemble all parts in reverse order. Set spring length “H”

and magnet gap “D”. Assemble manual release. See following

paragraph.

MANUAL RELEASE ASSEMBLY

(See Figure 3)

When assembling a standard manual release mechanism (Figure 3),

add only enough shim washers (13) to obtain proper release action.

Too many shim washers will prevent automatic reset when electrical

power is applied. Too few washers will prevent the motor shaft from

turning freely. Replace stop screws (14). Wind each torsion spring (11)

approximately 1/4 turn and hook spring loop over pin.

MAGNET COIL REPLACEMENT

(See Figures 3 & 4)

Remove magnet assembly as outlined under FRICTION DISC

REPLACEMENT.

Coils (18) are held in place with epoxy cement. Force coil off magnet

mounting plate and remove excess epoxy from all surfaces.

Replacement coils should be held in place with new epoxy cement.

The epoxy cement should be heat resistant and shock resistant.

Place an insulating washer (19 or 19a) below the coils. Order insulating

washers when ordering coils. An insulating washer can be cut to suit

when replacing only one coil on a multiple coil assembly.

When installing coils, it is very important to follow EXACTLY the

sequence of black and light colored leads as shown in wiring diagram

(Figure 2). The brake will not operate properly unless coils are all in

the correct position.

Figure 4. Fastening of Replacement Magnet Coils

Figure 3. Exploded View of Brake