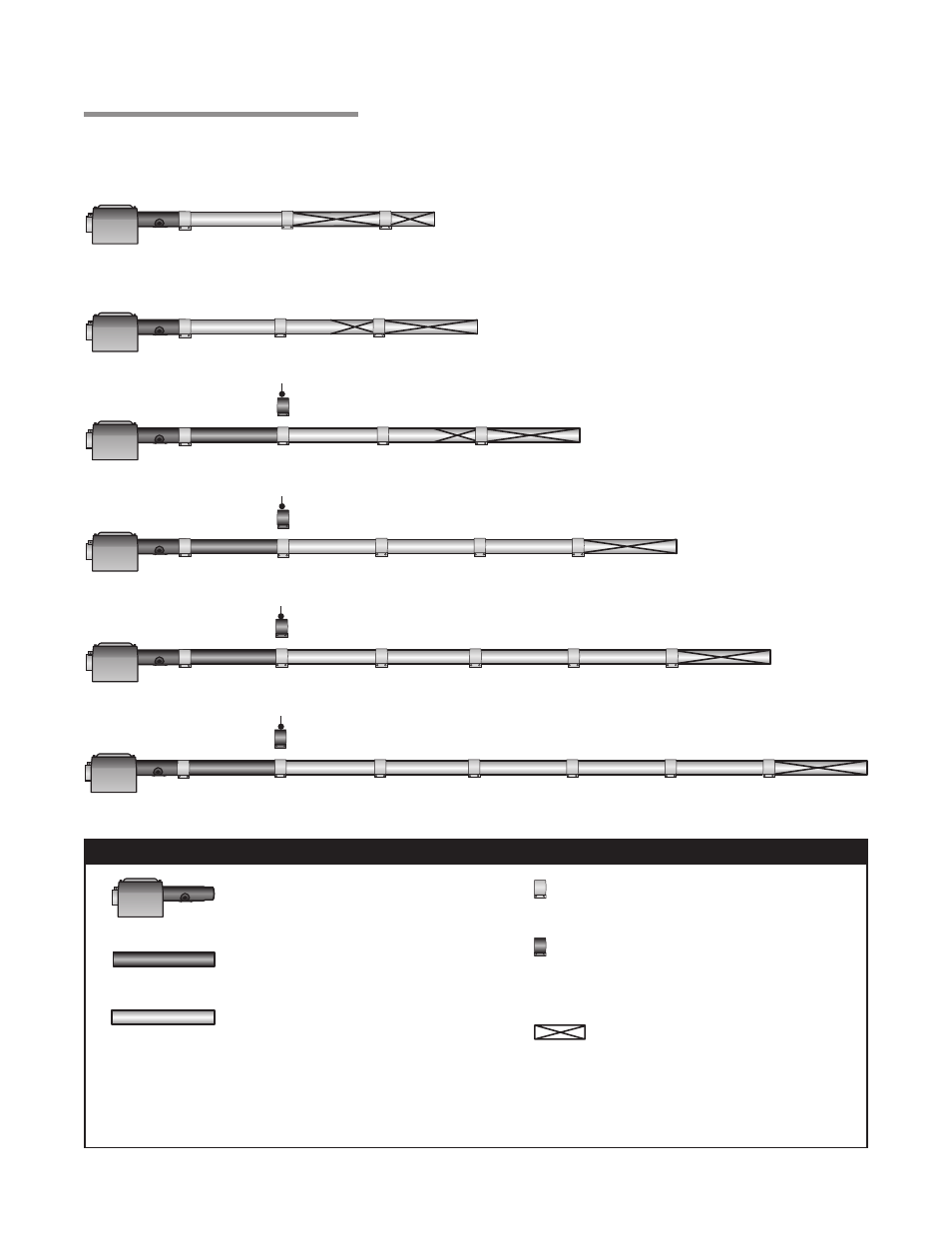

Tube installation sequence – Detroit Radiant Products Company MP Series User Manual

Page 17

Key

Tube Installation Sequence

25 Foot

50 Foot

60 Foot

30 Foot

40 Foot

70 Foot

Stainless steel clamp location on 150,000-200,000 BTU/h models (P/N: TP-220).

Stainless steel clamp location on 150,000-200,000 BTU/h models (P/N: TP-220).

Stainless steel clamp location on 200,000 BTU/h models (P/N: TP-220).

Stainless steel clamp location on 150,000 BTU/h models (P/N: TP-220).

17

MP

Series

Figure 2.9 •

Tube Installation Sequence

Burner Control Box with

16-inch Burner Tube

Black Coated Combustion

Chamber Tube*

P/N: TP-26A, TP-26B

Black Coated Aluminized Combustion

Chamber/Radiant Emitter Tube

P/N: TP-26A

Standard Tube Clamp

P/N: TP-21B

Stainless Steel Tube

Clamp (P/N: TP-220)

150,000-200,000 BTU/h models only . Located

between 1st and 2nd 10 ft . tube sections .

2.0

Installation

•

Tube Installation Sequence

Important! The combustion chamber & radiant tube sections must be installed in the following order .

Baffle Location

* Aluminized tubes (80,000 to 115,000 BTU/h models) P/N: TP-26A .

* Titan tubes (150,000 to 200,000 BTU/h models) P/N: TP-26B .

NOTE: Refer to the Tube Heater General Manual, Chart 3 .6 (Page 23) for secured reflector joints .