Mirion Technologies R600 Ventus Controller User Manual

Page 2

Specifications and Performance

The Quadtek R600 Control System comprises a complete schedule of

material for installation of a Quadtek High Temperature Television

System. The hardware package can be specified to work with the

complete range of Quadtek Ventus high temperature television cameras.

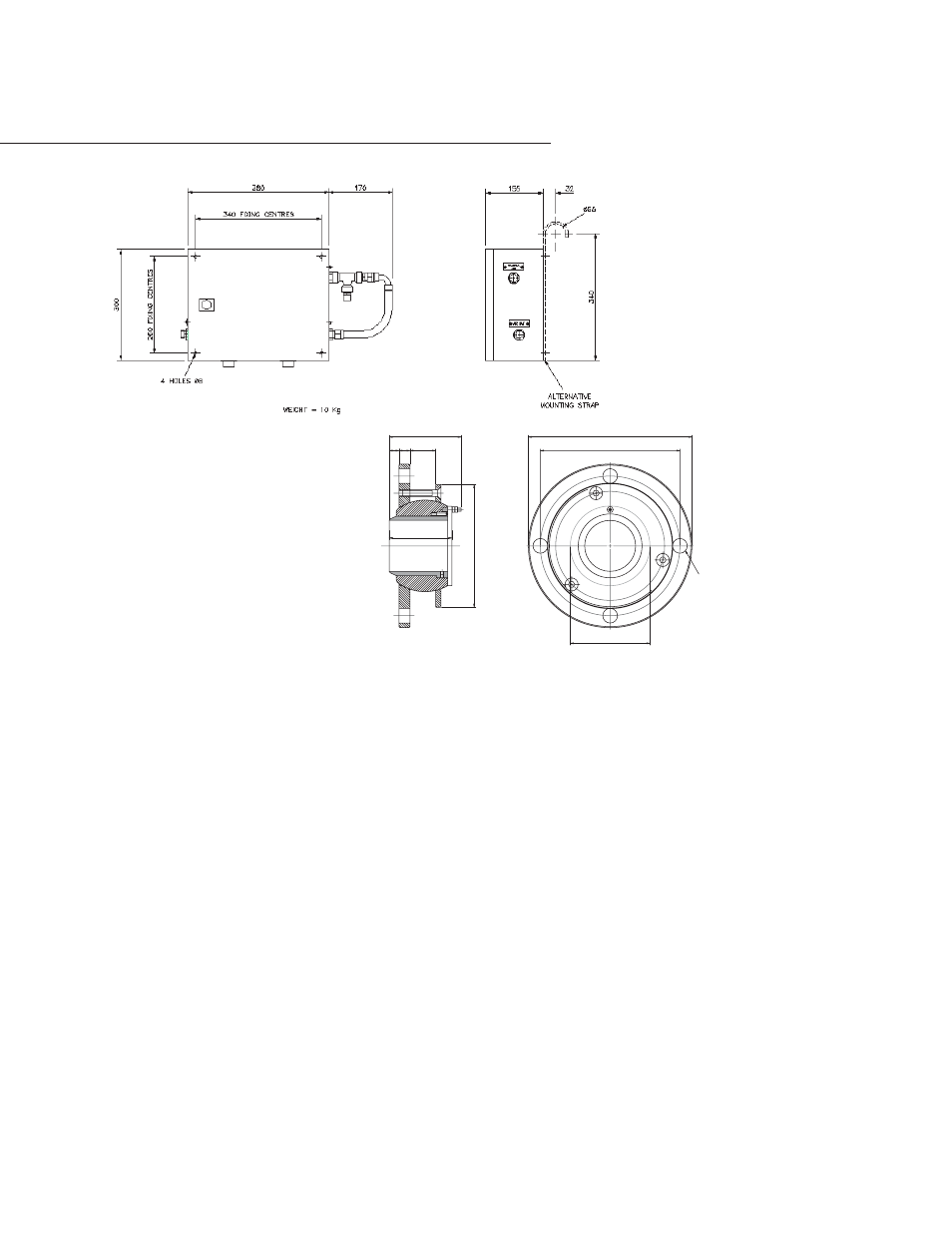

The Quadtek Ventus series cameras are also supplied with a mating

gimbal flange assembly, which allows for a simple four bolt fixing to a

boiler or furnace, the gimbal comprises a mounting flange, locking plate,

gimbal, shutter and sleeve. The sleeve mounts to the camera, setting the

insertion distance and providing for quick removal of the unit for

maintenance. The shutter acts as a retaining catch for the sleeve and

covers the viewing port when a camera is not fitted. By loosening the

bolts on the locking plate the gimbal can be adjusted to give ±10° of

axial movement for fine adjustment of the direction of camera/probe

view.

All cameras use a standard five meter composite cable for connection of

power, video and temperature sensing to the local Quadtek R600 Camera

Interface Unit. The cooling hoses are specific to the camera cooling

system, although all systems use a common five meter hose assembly

between the camera and Quadtek R600 Interface Unit for air cooling and

purging. The input compressed air supply is via a one meter hose

assembly to a filter regulator assembly comprising; 40 µm coalescing

filter with shut off valve, pressure relieving regulator and manual drain.

Termination of the plant compressed air supply is direct to the filter

regulator via a 1/2" BSP fitting. For water cooled systems, two

additional five meter hose assemblies and an additional one meter hose

assembly are provided for water supply and drain from the camera to the

local Quadtek R600 Interface Unit, and from there to the plant drain. All

hose assemblies use Aeroquip SH925 hose with 1/2" BSP brass fittings.

Optional coalescing filter assemblies and water filter/regulators are

available to clean coolant supplies to the specified conditions.

The system control and monitoring is provided from two wall mounted

enclosures which provide camera power, status sensing and alarm

outputs and a desk top free-standing 14” color display monitor. The R600

Camera Interface is mounted locally to the camera, while the Quadtek

R600 Control Box is located in the control room adjacent to the monitor,

where the operators can view the monitor and see the status indication.

Alternatively, both enclosures may be installed adjacent to one another

at the camera location; in this case, the voltage-free relay contacts are

used to annunciate faults in the control room.

The Quadtek R600 Camera Interface is selected with either an air flow or

water flow sensor depending upon the camera main cooling system and

operates from a low dc voltage supplied by the Quadtek R600 Camera

Control Box. The camera status is monitored by a thermocouple, coolant

flow switch and air purge pressure switch, which interfaces with a

printed circuit board providing full condition monitoring. A built-in self

test and calibration circuit are provided for simple system test and

commissioning of the status and alarm outputs to the Control Box. The

Camera Control Box can be supplied with a glanded cable entry or MIL

specification connectors, the main power supply is regulated to a low DC

supply to the local interface and a relay board provides status and alarm

indication with a remote output. An industrial grade color display

monitor provides high quality video from the camera / probe to the

operator. A full range of video monitors, switching and recording CCTV

components are available to meet specific needs. Please contact IST for

further information.

ш256.0

ш300.0

ш225.0

ш146.0

115

18 20

47

132

4 HOLES ø27 THRO'

EQUI-SPACED AS SHOWN