Introduction – Magnum Venus Plastech TESTING & ADJUSTING YOUR MVP PUMPING SYSTEM User Manual

Page 16

Testing & Adjusting Manual

Rev. 01/2013

Page | 16

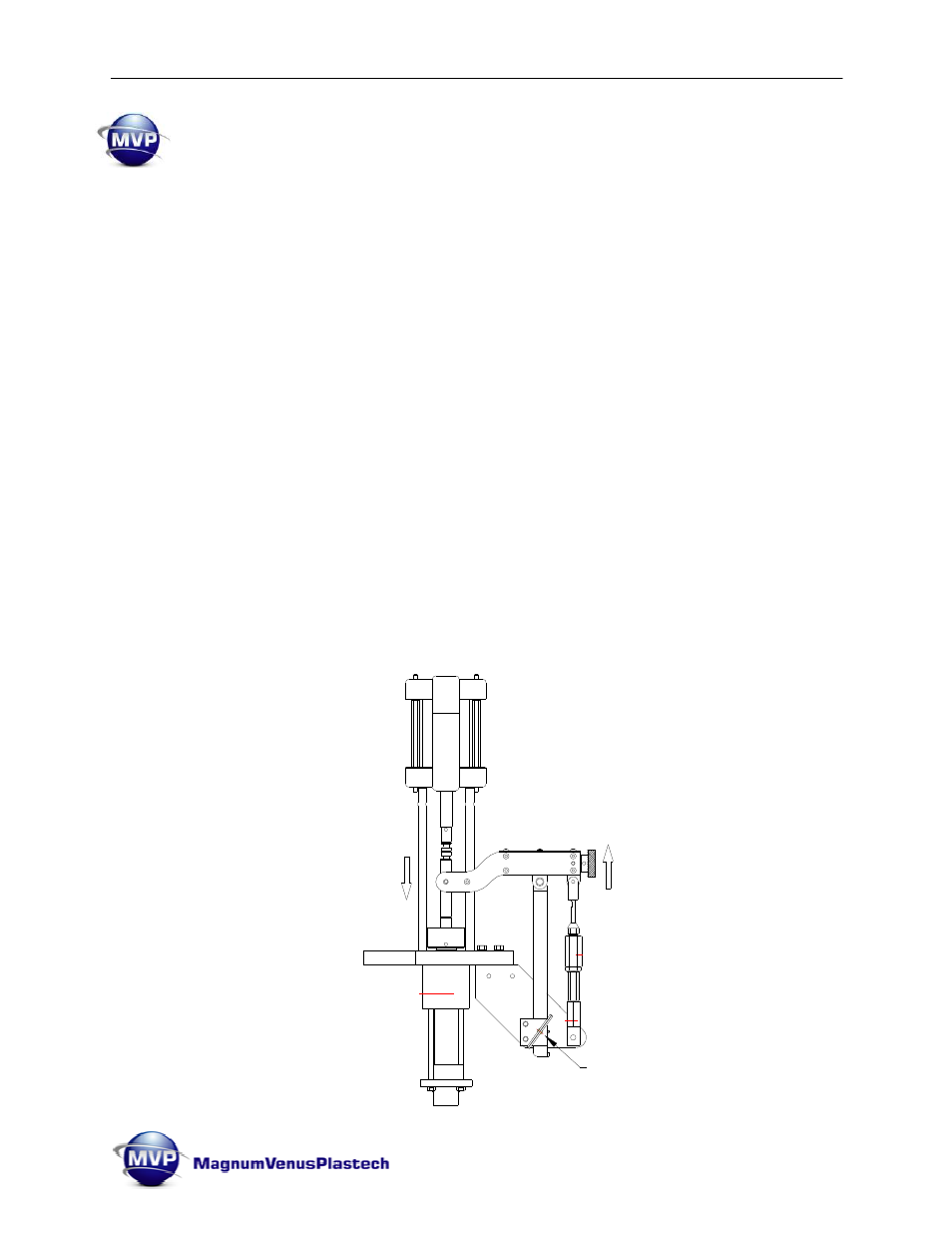

RESIN PUMP OUTLET

CATALYST PUMP OUTLET

PIVOT PIN

Introduction:

MVP has a variety of pumps in a wide range of configurations. Most of the pumping

systems are based on a “double acting piston pump”. Double acting piston pumps are a

two ball style pump which delivers material on both the up and down stroke. They are

driven by an air motor of which there are a variety of sizes. There are three basic resin

pump sizes; Gel coat – lower output systems, gel coat application, Chopper / Standard

– mid range output, most commonly used for chopper and wet out systems and High

Volume – high volume chopper systems and special or automatic equipment.

Each of these pumps has a corresponding catalyst / initiator pump which is attached by

a drive linkage. The catalyst / initiator pumps work on the same principles as the resin

pump but are driven through a linkage attached to the resin pump. The catalyst pump

and resin pump have a fixed ratio to each other, in that they move together pumping a

given amount of resin. This leads us to one of the major principles, since the catalyst

pump is attached to and driven by the resin pump, you can never get more of one

component just less of the other. The catalyst pump can not run on its own and pump

more catalyst; you can only have a problem with the resin pump and deliver less resin,

and the same is true for the catalyst.

Note: With the UPS (Ultra Proportioning System) when the resin pump is in the up

position the catalyst pump is in the down position, which means when the resin

pump is going up the catalyst pump is going down.