Laurel Electronics LAUREATE SERIES SCALE-WEIGHT METER User Manual

Page 14

14

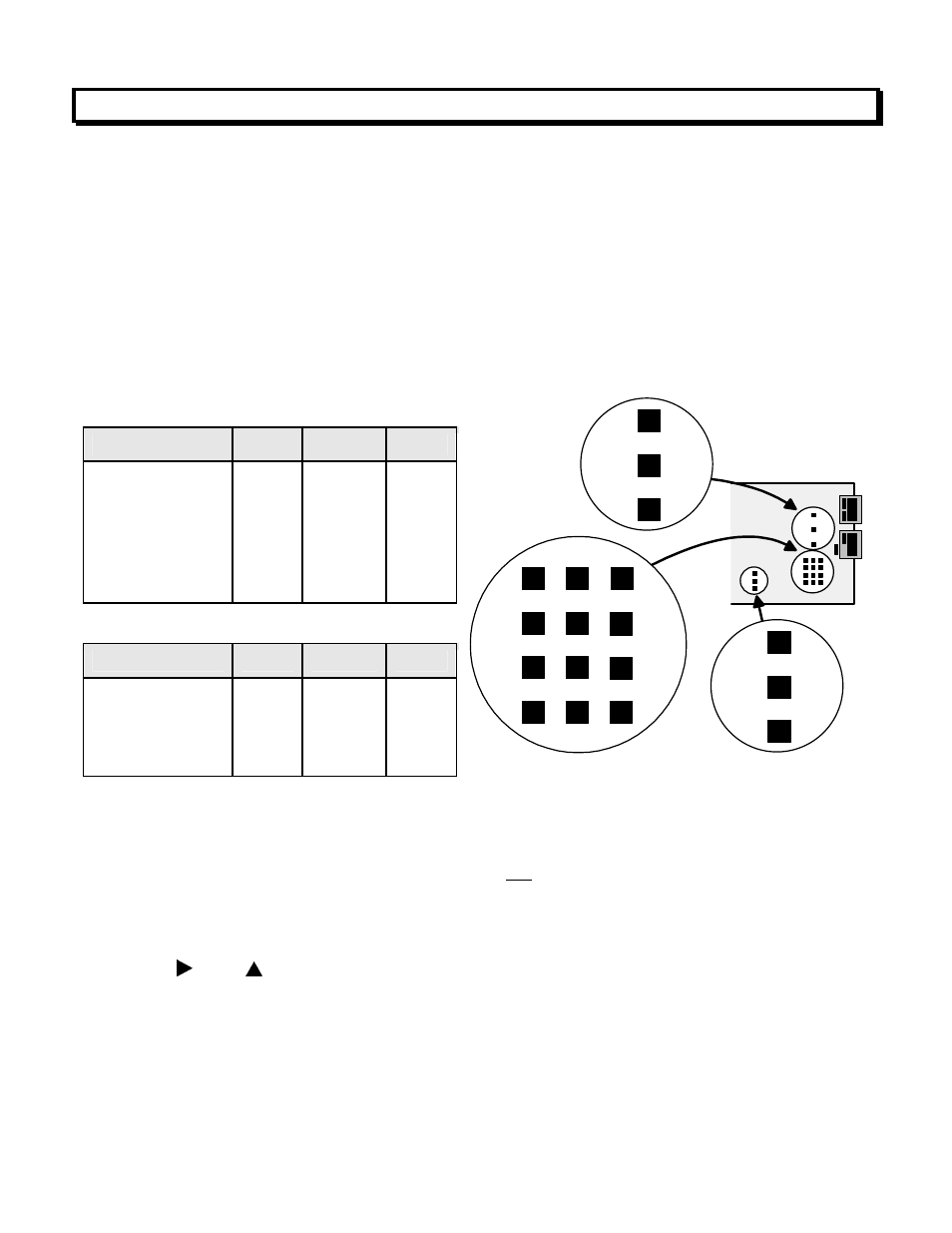

11. PROCESS & STRAIN INPUT JUMPERS

Process and strain input scale meters utilize the DC signal conditioner board, which offers

sensitivity to ±200 mV and can operate in a ratiometric mode, which removes effects caused

by variations in the excitation supply. This board needs to be configured via jumpers for the

desired voltage or current range. All signal ranges are factory calibrated with calibration factors

stored in EEPROM. The meter software recognizes the board and will bring up the appropriate

menu items for it; however, it does not recognize the jumper settings. Please see further

manual sections for relay output, analog output, communications, and transducer excitation

output.

RANGE SELECTION VIA JUMPERS

1. Letters indicate jumper position. Jumpers are installed on pins adjacent to letters.

2. Use 5 mm (0.2") jumpers for locations designated by a capital letter.

3. Use 2.5 mm (0.1") jumpers for locations designated by a lower case letter.

4. Store spare jumpers on an unused jumper post not associated with a capital letter.

SCALE & OFFSET SETUP

For process, strain, and load cell scale meters, scaling is normally set up from the front panel

using the

and

keys, but can also be set up via RS232/485 using PC-compatible

Instrument Setup software (available at no charge). The meter allows three scaling methods to

be selected: 1) Scale & Offset method, 2) Coordinates of 2 Points method, or 3) Reading

Coordinates of 2 Points method. Only menu items applicable to the selected method will be

presented. Please see the Glossary for an explanation of each method.

Voltage Ranges Jumpers

FS Input

E1

E2

E3

±200.00 mV

±2.0000 V

±20.000 V

±200.00 V

±300V (UL)

±600V (not UL)

A

A

B

B

B

B

f

f

h

h

g

g

b

a

b

a

a

a

Current Ranges Jumpers

FS Input

E1

E2

E3

±2.0000 mA

±20.000 mA

±200.00 mA

±5.000 A

A

A

A

A

e, g

d, g

c, g

a, b, g

b

b

b

b

E1

a

E2

b

E3

h

a

g

e

d

c

b

f

B

A