Photo eye sensor placement, Safety loop system installation – Controlled Products Systems Group RAM2000 User Manual

Page 11

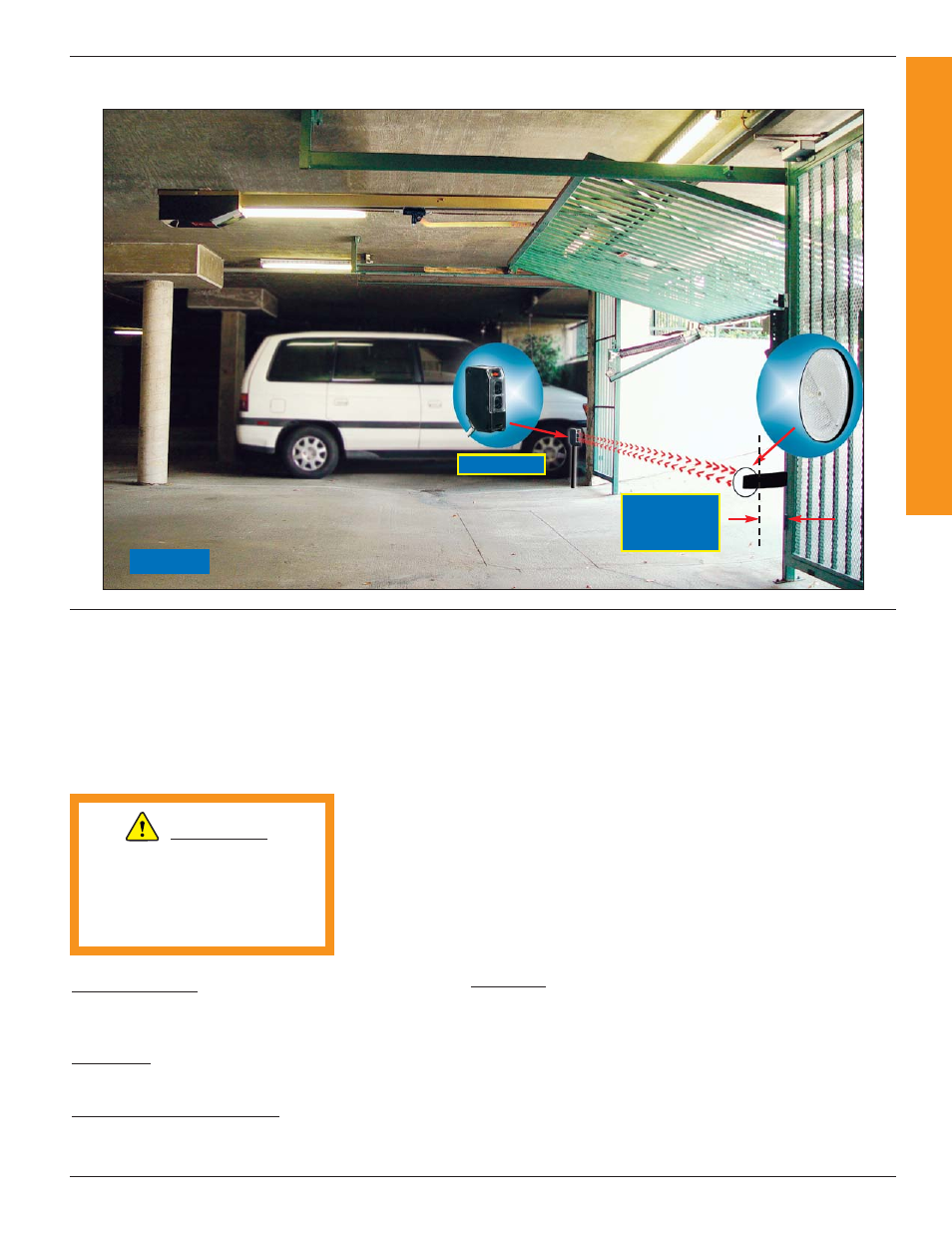

PHOTO EYE SENSOR PLACEMENT

9

RAMSET

RAM 2000 UL

- 2100 UL

- 2200 UL

Figure 7

SAFETY LOOP SYSTEM INSTALLATION

Ramset Gate Operators should not

be installed without non-contact

sensing devices such as Loop

Detectors, Photo Electric Sensors or

the equivalent.

A non-contact sensor (photoelectric

sensor or equivalent) and a contact

sensor (edge device or equivalent)

is required on each individual

installation to comply with UL325.

Reversing Loops on the ground floor,

prevents gate from closing when vehi-

cle is in loop area.

Exit Loops on the ground floor, opens

gate when vehicle crosses loop area.

Photoelectric Safety Sensor

(Photo Eye) prevents the gate from

closing when any object interrupts

the beam.

INSTRUCTIONS:

Mark the loop layout on the pavement.

The pavement is typically cut to a

depth of approximately 1 1/2" to 2"

using a 1/4" wide blade. The slot is

then cleaned with water and then

blown out with compressed air. This

will assure that all sharp particles are

removed from the slot. The corners of

all square or rectangular loops should

have 45º cuts to prevent sharp cor-

ners from puncturing the loop wire.

The turns of wire are then installed in

the bottom of the slot and held into

place with foam backer rod. This will

assure that the wire is held in place

when the sealant is added to the slot.

Loop wires should be twisted at least

8 to 10 turns per foot from the point

where they leave the loop and start

toward the side of the roadway-down

the lead-in slot. The sealant used in

the loop and lead-in slot should be pli-

able and should "give" with tempera-

ture changes in the pavement.

The roadway loop shown in figures 8

and 9 is a typical configuration for a

street or roadway installation. The two

wires leave the rectangular loop and

are placed in another slot to exit the

roadway. The wires used in the main

loop and the exit slot must be one

continuous piece. No splices can be

made in any part of the installation.

Apply sealant to whole sawcut as well

as the main loop. The wires are then

spliced to the lead-in cable at the con-

crete pull box. All splices must be sol-

dered! Do Not Use wire nuts or

crimp type connectors! Tinned cop-

per crimped connections can be used

to hold the wires together as log as

they are then soldered!

The top of the backer rod should be at

least 1" below the level of the pave-

ment.

www.ramsetinc.com

Photo Eye

Reflector

6" Clearance

from spring

WARNING:

6"

TO LINE UP

WITH EACH OTHER