Controlled Products Systems Group 8300SL User Manual

Page 9

7

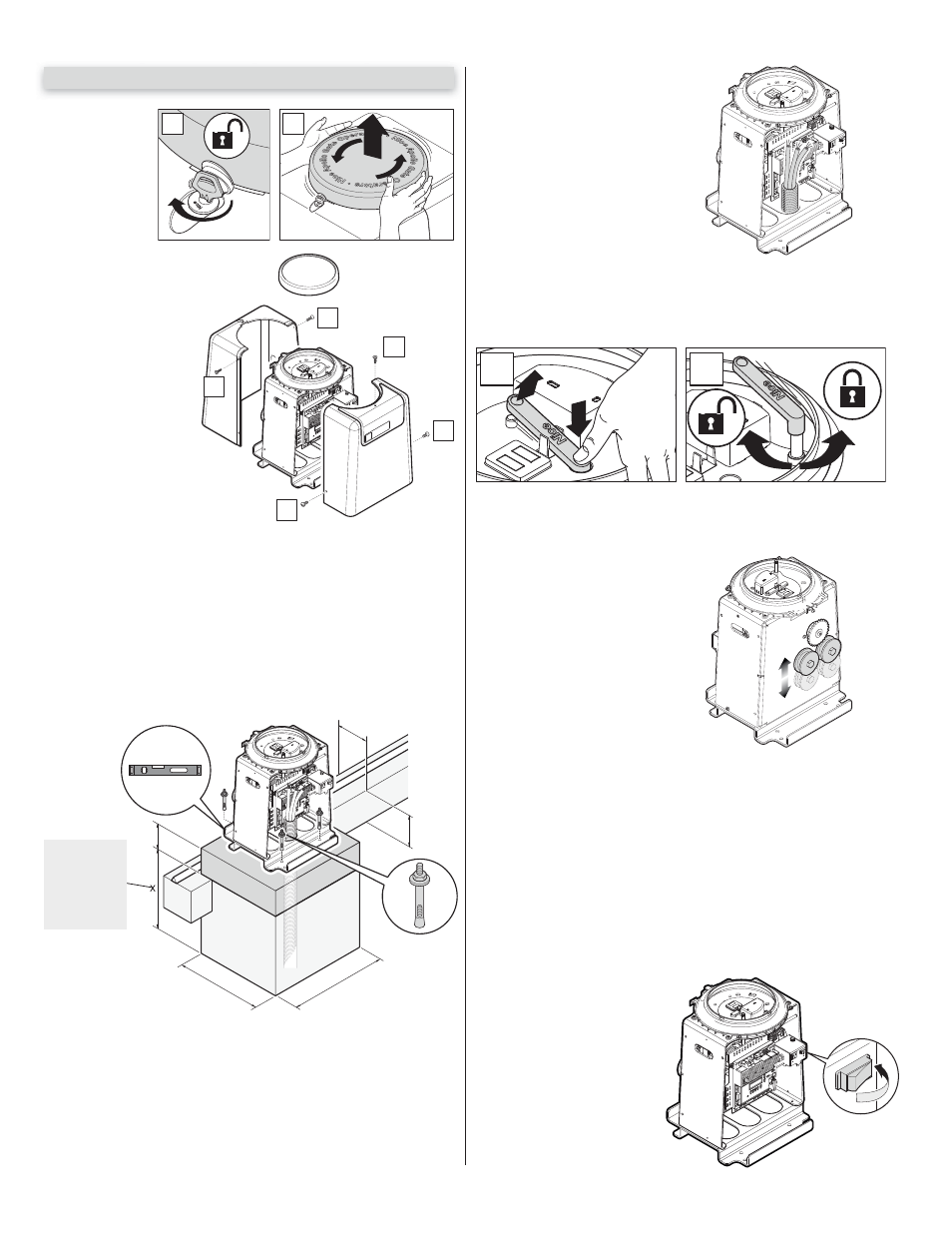

6.4 - Step four-manual release

Locate the manual release handle. Turn the manual release handle counter-

clockwise until the handle stops. The chain drive assembly is now disengaged

and the gate may be operated by hand.

1

2

Figure 6 - MANUAL RELEASE

6WHSƄYHFKDLQDVVHPEO\

Connect Chain assembly to sprocket

assembly and test gate for free move-

ment. (Should move freely in both

directions) Push the gate by hand to

the full movement in each direction

to ensure it does not bind or catch in

@MXL@MMDQ

1DEDQSNjFTQDR@MC

30 for diagrams of correct and incor-

rect installation).

Figure 7 - BRACKET

6.6 - Learning and programming

These steps begin the basic “Learning” programming of the gate opener unit.

Most all of the features and programming are pre-set and already set up for

most standard installations. The installer most often will only be required to

plug the unit into electrical power, connect the chain to the sprocket assembly

and by setting the limits on the gate movement, and then “learning” the unit. In

most cases this is the extent of the basic programming procedure. If the unit

is not in LEARNING MODE see section 6.9 to place the unit into this mode.

Apollo has taken great care to simplify the installation, operation and safety

of this device and to ensure longevity and reliability of the unit over time. The

learning procedure consists of the following steps.

+RZWRVHWXSIRUƄUVWXVH

1. Install electrical power con-

nections to the gate opener

unit. Ensure the power switch

is in the OFF position prior to

touching any of the power

connections. Install all gate

accessories such as Photo-

Eye’s, Sensors, Loops and

other safety devices.

6.1 - Step one-location

Locate the area in which the opener shall be located.

6.2 - Step two-concrete

%@AQHB@SD@BNMBQDSDO@CRSQTBSTQDRTEjBHDMSSNRS@AHKHYD@MCLNTMSSGDF@SD

opener. Please consult the local building dept. and/or a structural engineer to

ATHKC@BNMBQDSDO@CSG@SLDDSRATHKCHMFBNCDR@MCHRRTEjBHDMSENQSGDRNHK

type and climate and capable of supporting the lateral loads imposed by the

NODQ@SNQCTQHMFNODQ@SHNM

2DDjFTQDENQOQNODQHMRS@KK@SHNM

6.3 - Step three-physical mounting

Drill and insert Redhead (1/2” x 3 1/3”) concrete anchors into the concrete

RTEjBHDMSSNOQNODQKXLNTMSSGDF@SDNODMDQ

,NTMSHMFONRHSHNMLTRSAD@

minimum distance of 4 inches distance between the gate and center chain

CQHUDROQNBJDS

1DEDQSNjFTQD.ODMSGDSNOBNUDQTRHMFSGDRTOOKHDCJDX

1DEDQSNjFTQD

1DLNUDSGDSNO@MCRHCDBNUDQRSNF@HM@BBDRRSNLNTMS-

ing holes. Set the unit in place and attach wiring as indicated in the wiring

section 9.0 Wiring and Connections of this manual.

10”

8”

x 4

6”

24”

20”

6 - INSTALLATION PROCEDURES

3

3

1

2

2

0

I

Figure 3 - COVER REMOVAL

Remove side bolts and

covers to access interior

for installation.

Remove gate operator

cover screws accor-

ding to the numbered

sequence as shown.

1

2

1. Remove top

cover assembly by

unlocking the lid

with the supplied

key.

2. Turn lid counter-

clockwise then

remove.

MAKE SURE ALL POWER IS

DISCONNECTED PRIOR TO

ANY SERVICE OR INSTALLA-

TION.

Figure 5 - WIRING

BELOW

THE FROST

LINE

CHECK

ALL LOCAL

CODES

Figure 8 - SETTING UP POWER

Figure 4

SAMPL$+ 8.43