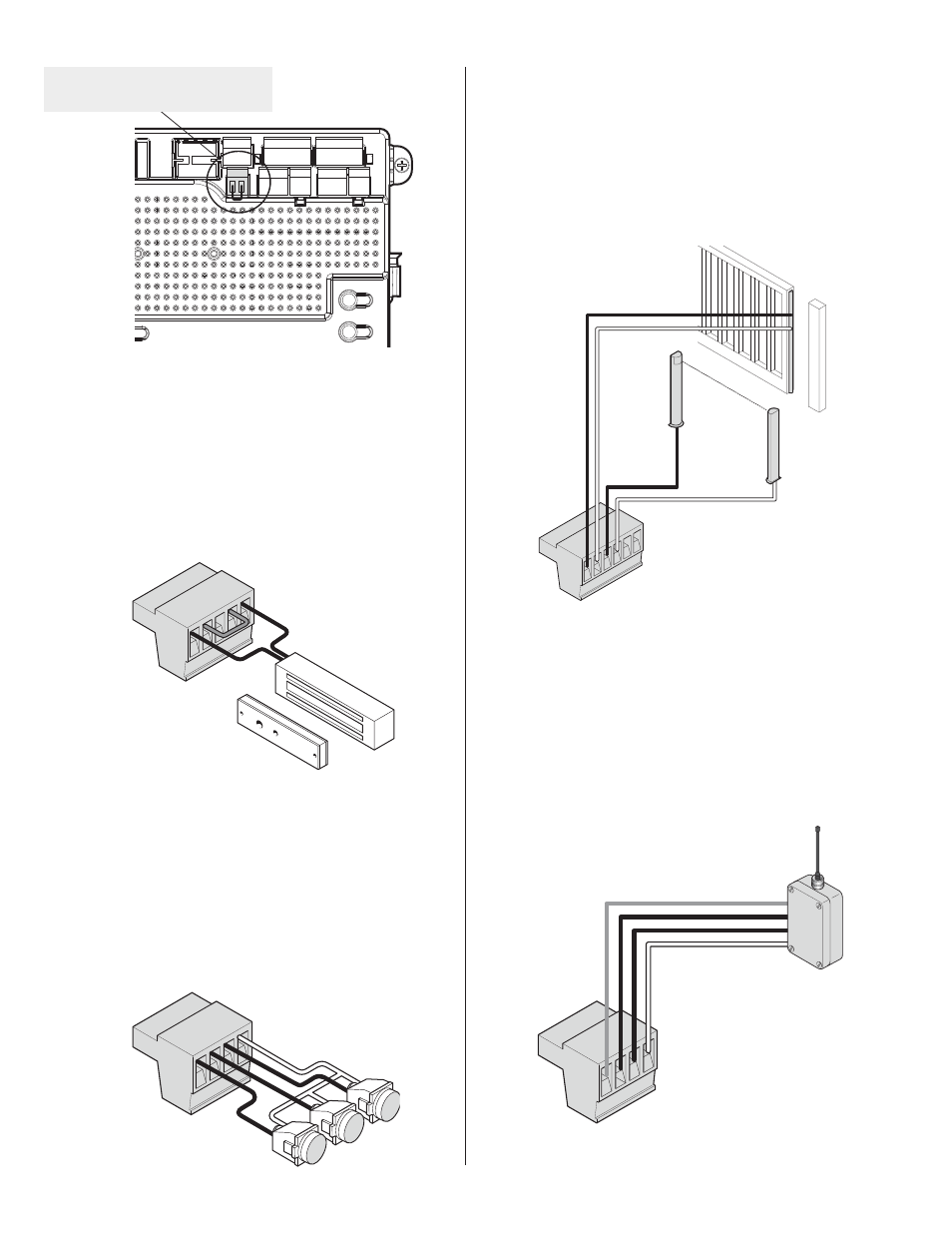

5 - exit and edge inputs wiring diagram, 6 - radio receiver connection (third party), 3 - magnetic lock connection – Controlled Products Systems Group 8300SL User Manual

Page 15: 4 - guard station connection

13

10.5 - Exit and edge inputs wiring diagram

28 EDGE

29 GND

30 EXIT

31 GND

3GD$#&$HMOTSL@XADBNMjFTQDC@R@LNMHSNQDC - +.&HMOTSNQ#(&(-

TAL (NC or NO) input. The EDGE sensor input is intended for ANSI/UL 325

listed gate edge sensors to protect against entrapment and hazardous pinch

points along the moving edge of the closing gate. The EXIT sensor input is

provided to activate to open the gate, or re-open a closing gate, upon sens-

ing an exiting vehicle.

Figure 24 - EXIT AND EDGE INPUTS

10.6 - Radio receiver connection (third party)

38 12V

39 OPEN

40 CLOSE

41 GND

The customer supplied radio receiver allows the gate operator to be operated

via remote, such as wireless key-card readers or user remote controls. Con-

necting the Open (39) and Close (40) pins together with a receiver enables

RHMFKDATSSNMF@SDBNMSQNK

3GHRBNMjFTQ@SHNM@KKNVR@RHMFKDATSSNMSNBNMSQNK

the gate in the following sequence:

Press - Gate Open

Press - Gate Stop

Press - Gate Close

Press - Gate Stop

Figure 25 - RADIO RECEIVER CONNECTION

Figure 21 - FAIL SAFE CONNECTION

10.3 - Magnetic lock connection

7 NC

8 Com (Common)

9 NO

10 GND

11 V+

This connection is used to install the magnetic lock. In this instance a gate

can be locked magnetically to prevent a forced opening. Connections to this

L@XADCHEEDQDMSSG@MRGNVM

"NMRTKSKNBJL@MT@KENQRODBHjBRNMHMRS@KK@SHNM

and wiring.

Figure 22 - MAGNETIC LOCK

CONNECTION

10.4 - Guard station connection

34 OPEN

35 STOP

36 CLOSE

37 GND

With a Guard Station switch in place, a user could operate the gate by push-

ing the respective buttons for the command that is desired. Gate Open, Stop,

@MC"[email protected], ++8./$--.@MC

-.1, ++8"+.2$#-"LNLDMS@QXRVHSBGDR

NOTE: If guard station inputs are not used, STOP (35) and GND (32) need

to be tied together.

Figure 23 - GUARD STATION

CONNECTION

*36:,

:;67

67,5

56

5*

56

Fail Safe connector with jumper installed on

the Primary motor control connectors

28

29

30

31

32

33

38

39

40

41