5 resolver alignment -36 – CONTREX CXB2040 User Manual

Page 38

8900 Zachary Lane N., Maple Grove, MN 55369 U.S.A.

35

6.5 RESOLVER ALIGNMENT:

Note:

CONTREX motors with built-in resolvers are factory aligned. Consult a CONTREX

applications engineer prior to attempting a resolver realignment. Failure to do so may void the warranty.

Note:

Consult a CONTREX applications engineer before aligning a non-CONTREX motor/resolver.

Some motor/resolvers require procedures other than that described here.

Note: Dip-switches S3-1, S3-2, S3-3 and S3-4 allow the converter to be operated in one of eight

modes. The first six modes set the number of motor "poles". One pole corresponds to one magnet, thus a

motor with two "north" and two "south" magnets has four poles. The number of electrical revolutions is

equal to one-half the number of poles. An electrical revolution refers to the arc-length the motor will

rotate when one complete sine-wave is applied. Therefore, a four-pole motor has two electrical

revolutions and requires two sine-waves to make one mechanical (shaft) revolution. The significance of

this is, any motor with more than one electrical revolution will have more than one electrical "index" (0

o

position), while there is only one mechanical index. From an electrical viewpoint, any index may be used,

however from a mechanical viewpoint, using a different electrical index may alter the mechanical index

by as much as 180

o

from its previous position. This will show itself as a change in where the encoder

index (channel Z) pulse occurs.

Note that the emulated encoder has an index per mechanical (shaft) revolution.

Of the remaining two modes, the INDEX is used to generate an index output and is used for resolver

alignment.

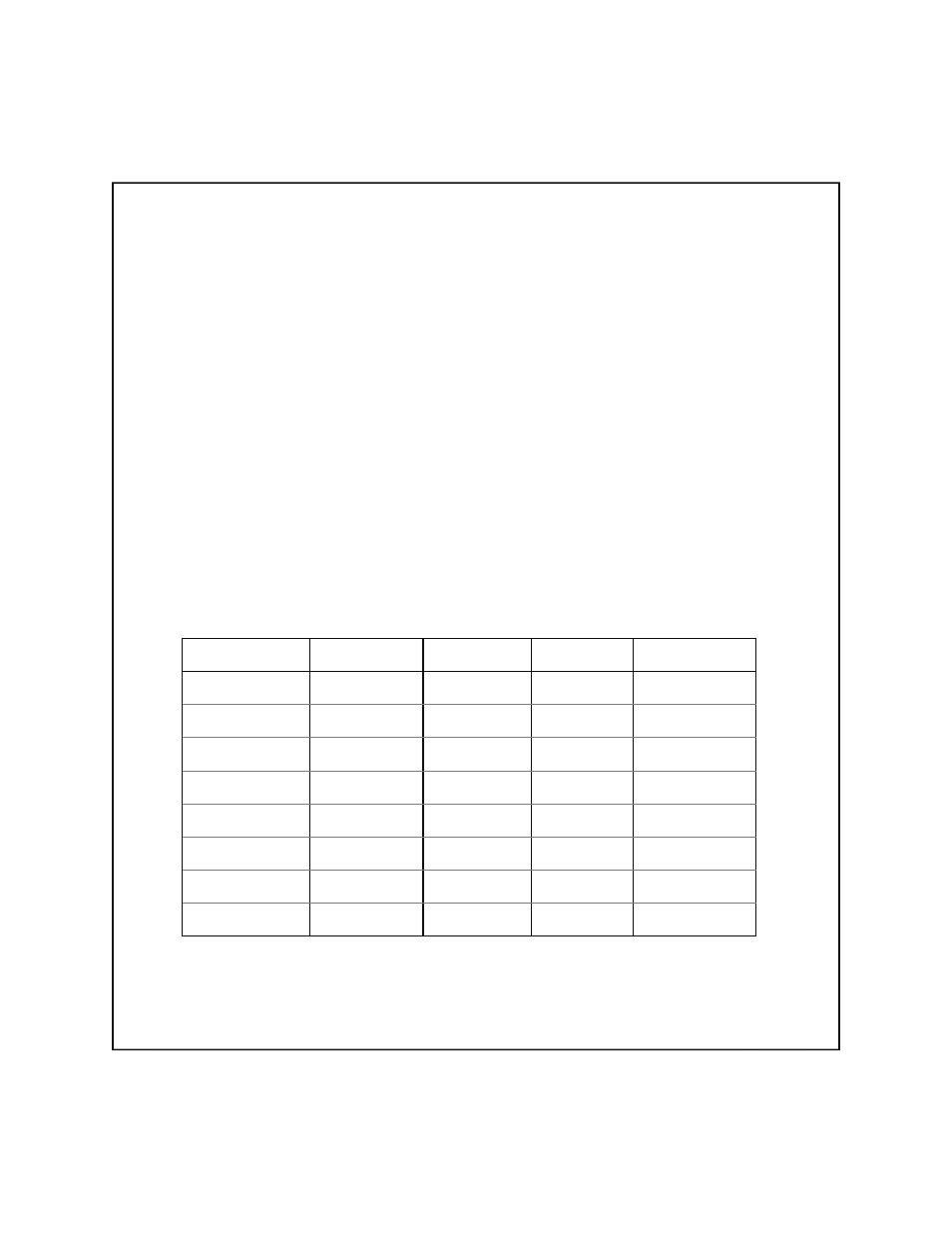

MOTOR:

S3-1

S3-2

S3-3

S3-4

2 POLE

ON

ON

ON

ON

4 POLE

ON

ON

ON

OFF

6 POLE

ON

ON

OFF

ON

8 POLE

ON

ON

OFF

OFF

10 POLE

ON

OFF

ON

ON

12 POLE

ON

OFF

ON

OFF

ZERO

ON

OFF

OFF

ON

INDEX

ON

OFF

OFF

OFF

CHAPTER 6: START UP AND CALIBRATION