4 mounting the transducer – Cleveland Motion Controls ULTRA ISC CARTRIDGE TRANSDUCER REV AA User Manual

Page 28

U

LTRA

S

ERIES

S

TATIONARY

S

HAFT

T

RANSDUCER

T

ECHNICAL

M

ANUAL

MAN-70430-0

R

EV

AA

20

4.4 Mounting the Transducer

The mounting surfaces for the transducer should be flat and parallel to each other. Remove any loose paint,

rust or scale from the machine frame before mounting. A clean metallic surface helps ensure that the body

of the transducer is at frame potential.

Table F – Steps for Mounting an Ultra Series Transducer

If you are using this

type of Mounting

style:

Then, perform these steps:

Stud (S)

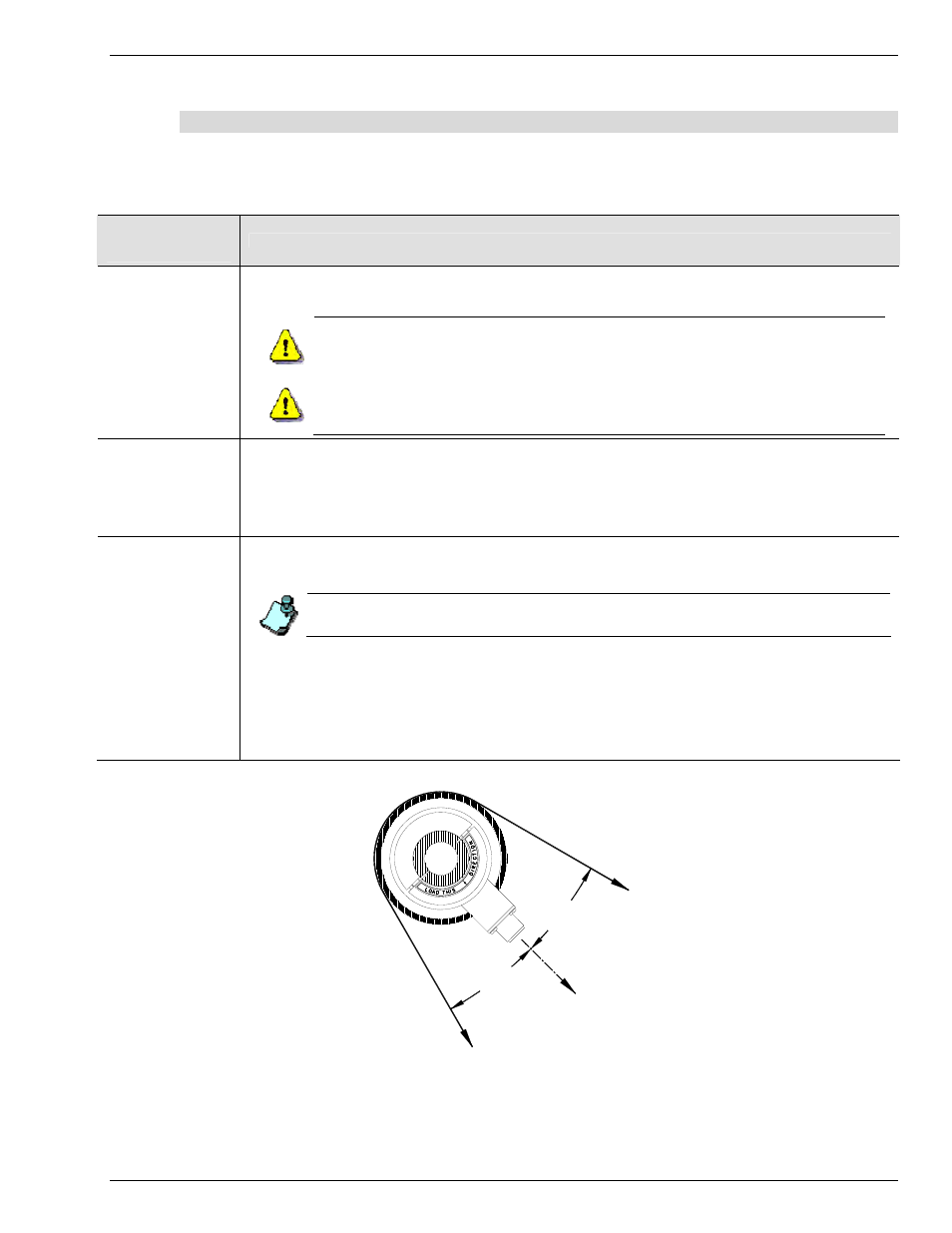

1. Before tightening the mounting bolt, rotate the transducer body until the force direction (indicated by the arrow

on the label) is aligned with the vector of the web force. The vector of the web force is the bisector of the wrap

angle. Refer to Figure 13.

Rolls often have an uninterrupted shaft that extends to form the journals. Though the roll

may be described as having a “dead shaft”, neither journal end can rotate independently of

the other. Attempting to rotate one transducer, while the other end of the roll is clamped

can result in damage to the transducer.

Make sure that the bolt is not too long so that it bottoms inside the transducer and causes

damage.

Pillow Block and

Bearing

Replacement (PB,

BR)

1. Loosely mount the transducer by lightly tightening the four (4) socket head cap screws that hold the lock plate to

the back of the transducer.

2. Rotate the body of the transducer body until the direction of the force (indicated by the arrow on the label) is

aligned with the vector of the web force.

3. Tighten the four (4) socket head cap screws to securely clamp the transducer in position.

Flange (F)

1. Before drilling the four (4) mounting holes, contemplate the orientation of the transducer taking into

consideration the location of the mounting screws. Be sure that the screws do not interfere with the position of

the connector. An optimal location for mounting holes also lets you maximize rotational alignment range.

Do not use the flange assembly as a drill template while not mounted to the transducer. The spacing

between flange halves is different when the transducer body is added.

2. Adjust the alignment of the transducer. First, be sure that the four (4) flange bolts are loose and then, loosen the

two (2) bolts that draw the flange halves together.

3. Rotate the body of the transducer body until the direction of the force, indicated by the arrow on the label, is

aligned with the vector of the web force.

4. Secure the flange to the transducer by tightening the two (2) socket head cap screws that draw the flange halves

together. Finish by tightening the four (4) bolts that draw the flange to the mounting surface.

WRAP

ANGLE

BISCETOR

WRAP

ANGLE

BISECTOR

LOAD

DIRECTION

W

E

B

W

EB

Figure 13 - Proper Orientation of the Cartridge Transducer