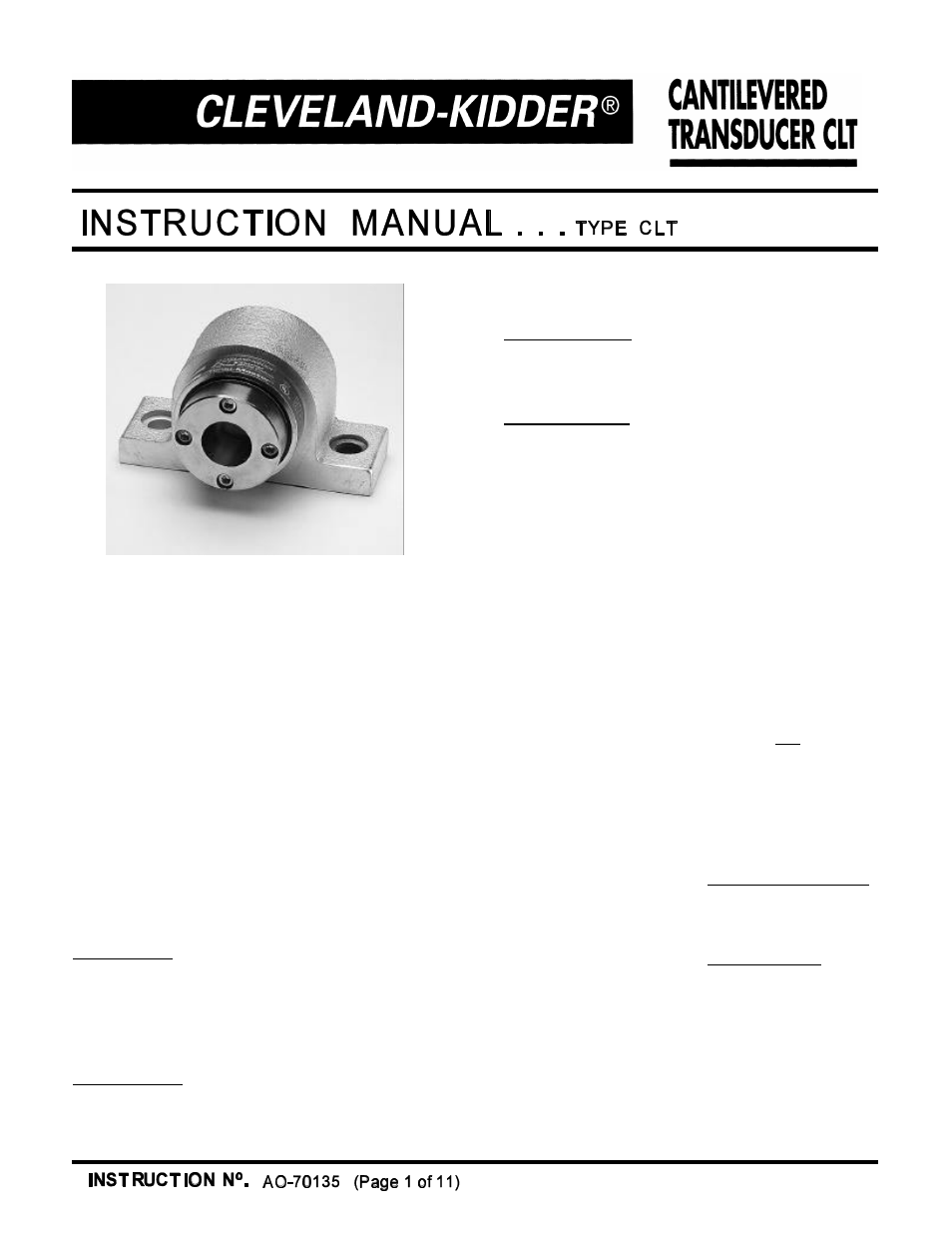

Cleveland Motion Controls Classic CLT Cantilevered Transducer REV AA User Manual

Cleveland Motion Controls Sensors

1.0 GENERAL INFORMATION

1.1

RECEIVING AND UNPACKING

Handle and unpack the equipment carefully.

Immediately upon arrival, check the shipment against the

packing list. Any damage should be reported

immediately to the carrier and to the nearest CMC®

representative.

Equipment which will not be installed immediately should

be stored in a clean, dry location. Precautions should be

taken to prevent moisture, dust and dirt from

accumulating in storage and installation area.

1.2

PRECAUTIONS

1.2.1 Shipping - It is recommended that the sensing roll

be removed when the machine is shipped with the

transducers mounted. The shock and vibration

transmitted to the transducers by the sensing roll during

transporting can damage them.

1.2.2 Handling - An impact such as dropping the

transducer or a sharp blow to the transducer can

damage it. The unit should be completely surrounded by

a soft foam cushion when being transported.

1.2.3 Overloading - Repetitive overloading above the

maximum working force, shock or severe overloading

should be avoided because they can damage the unit.

1.2.4 Overvoltage - The excitation voltage should not

exceed 10 VDC or AC (RMS). Excessive voltage can

destroy the semiconductor strain gages.

The voltage between the gage and beam or base

(ground) should not exceed a peak of 50 volts.

Exceeding this voltage can cause an insulation

breakdown between the gage and the beam.

1.3

SPECIFICATIONS

Gage Resistance

- 220 ohms per leg nominal

Gage Factor

- 100 nominal

Excitation Voltage

- 5.6 VDC or VAC (RMS)

nominal. Not to exceed

10 VDC or VAC (RMS)

Output Signal

at Rated MWF

- 20mV/V, 30mV/V

(Alum, Steel)

Size 1 Steel, Size 2 Steel

Output Impedance

- Approximately 850 ohms

at 25

EC

Size 1 Aluminum

- Approximately 120 ohms

at 25

EC

Required Input

Impedance of

Tension Amplifier

- 5000 ohms

Insulation Breakdown

Voltage Gage to Beam

- 50 volts peak

Operating Temperature

- 0

EF to +150EF