3 pre-installation precautions, 1 roll balance, 2 critical roll speed – Cleveland Motion Controls ULTRA ISC CARTRIDGE TRANSDUCER REV AA User Manual

Page 27: 3 avoiding damage to the transducer

MAN-70430-0

R

EV

AA

U

LTRA

S

ERIES

S

TATIONARY

S

HAFT

T

RANSDUCER

T

ECHNICAL

M

ANUAL

W

1.75 1.88

Y

1/2 1/2

Z

1.50 1.70

W

44.5 47.6

Y

M-12 M12

Z

38.1 43.2

*Maximum shaft

mm

diameter 30.00

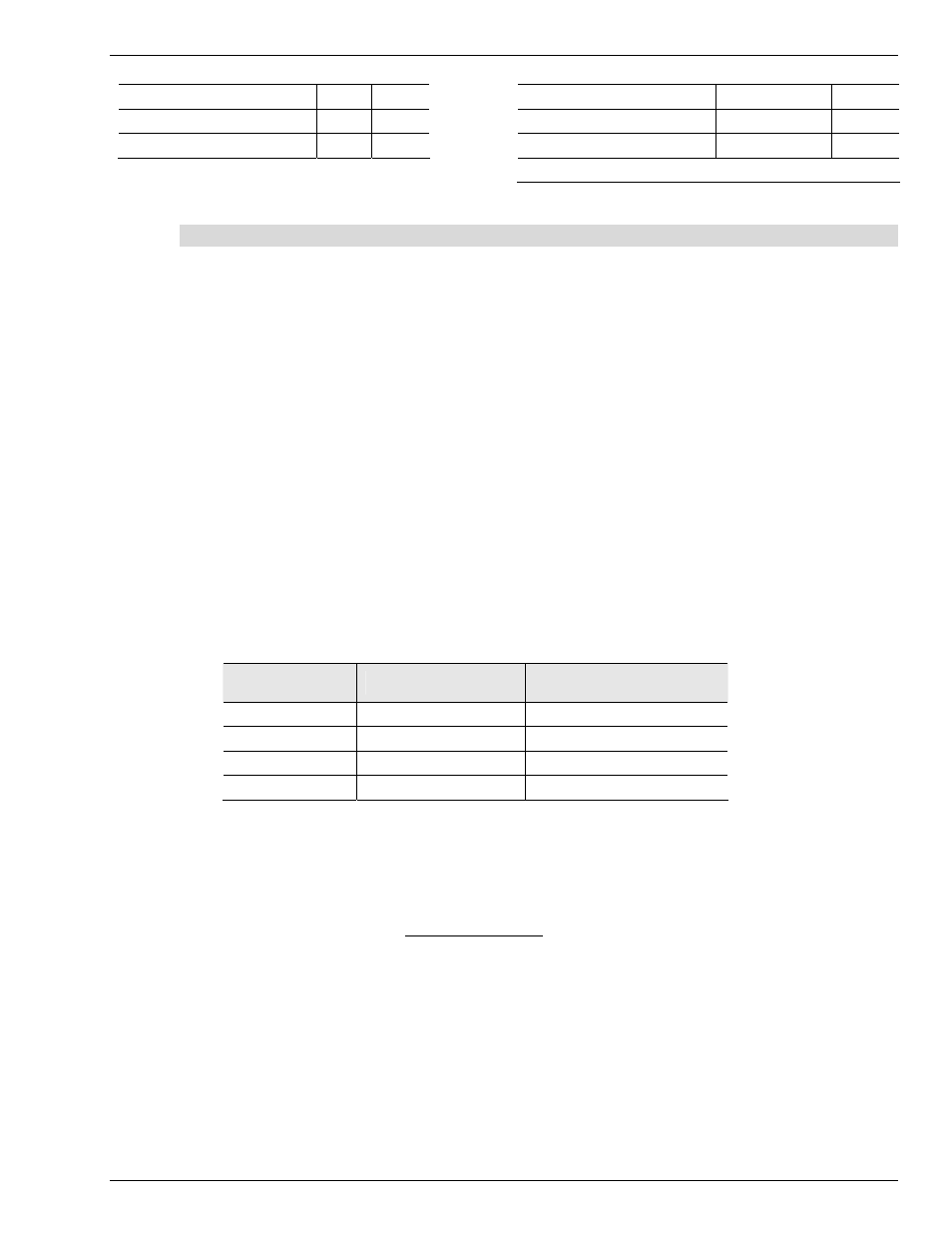

Figure 12 – Mounting Dimensions

4.3 Pre-Installation Precautions

4.3.1 R

OLL

B

ALANCE

The sensing roll must be adequately balanced. Understand that the balance of the sensing roll will be more

demanding than that typically needed in general rotating machinery. The goal goes beyond just limiting the

force to which bearings will be subjected, but rather to minimize the generation of an unintended noise

component in the transducer tension signal. The centrifugal force caused by imbalance can be estimated

using the following formula:

F = (1.77 x 10

-6

) x W x R x (RPM)

2

Where:

F = centrifugal force (in units of lb-f)

W = weight imbalance (in units of ounces)

R = radius of displacement, distance of imbalance weight from roll axis of rotation (in inches)

RPM = Revolution per minute

The force increase is equal to the square of the RPM, or in other words, doubling the RPM causes four

times the imbalance force. Because rolls tend to have a high length-to-diameter ratio, two-plane (dynamic)

balancing is recommended. Balancing is particularly needed where higher RPMs and lower web forces are

involved.

To illustrate how much imbalance induced “noise” could be generated, the following table shows the force

disturbance for various ISO balance grades for an illustrative case of a 20 pound roll (4” diameter x 36”

long, aluminum ) rotating at 1500 RPM.

Balance Grade

(ISO 1940/1)

Residual Imbalance

Resultant Force due to

Residual Imbalance

G16

1.25 oz-in

+/- 5 lb-f at 25 Hz

G6.3

0.5 oz-in

+/- 2 lb-f at 25 Hz

G2.5

0.2 oz-in

+/- 0.8 lb-f at 25 Hz

G1

0.08 oz-in

+/- 0.3 lb-f at 25 Hz

4.3.2 C

RITICAL

R

OLL

S

PEED

Even with a balanced roll, a vibration can be set up in a stationary shaft. If this vibration (in cycles per

minute) occurs at the harmonic frequency of the shaft, the transducers can be damaged. To determine

critical roll speed, use the following formula:

Critical roll speed in RPM = 4.8 x 10

6

x Shaft O.D.

(Shaft Length)

2

(Dimensions are in inches)

To assure that this issue is avoided, the critical roll speed should be at least 20% above the roll speed

attained at maximum web speed.

4.3.3 A

VOIDING

D

AMAGE

T

O THE

T

RANSDUCER

To avoid damaging the transducers, refrain from repetitive overloading above the maximum working force

or severe overloading.

19