Cashco 987 User Manual

Page 7

7

IOM-987

11. Remove seat ring O-ring seal (5) from seat

ring (3). Inspect O-ring (5) for signs of failure

to seal, then discard.

12. Remove body (1) from vise and place body

(1) and seat ring (3) into a suitable cleaning

sol vent.

13. For valves equipped with Opt-27 Viscous

Service Bonnet, ensure that the two equal-

iz ing passageways located in bonnet (2) are

fully open.

14. For valves equipped with a composition seat

as a part of the plug/stem sub as sem bly (4), the

parts are mechanically pressed together such

that the com po si tion seat is non-re place able.

A new plug/stem subassembly (4) must be

sup plied in order to replace the com po si tion

seat.

15. After soaking, remove all parts (1,2,3,4,7,11)

and inspect for any signs of wear or cor ro sion;

replace all worn parts with new parts. Bonnet

(2) pack ing box and stem (4) sealing zones

must be fi nished to a 16R

a

surface or better.

16. Place body (1) into a vise with bonnet-zone

on topside.

17. Place a new O-ring seal (5) onto the seat ring

(3). Reinstall the seat ring (3) into the body (1)

by rotating the seat ring (3) CW (viewed from

above). Using the steel bar tool, fi rmly tighten

the seat ring (3). NOTE: Do not over-tighten

the seat ring (3) to prevent galling of threads.

18. Place a new O-ring seal (6) into the bon net's

(2) recess in the body (1).

19. Place TFE sealant tape over threaded-end of

stem (4), cov er ing all the peaks.

20. Place plug/stem subassembly (4) with the plug-

end into the seat ring (3), and the thread ed-end

directed upwards. Place lower end of bon net

(2) over thread ed end of stem (4) and fully

lower bonnet (2) until prop er ly aligned in body

(1) recess.

21. Place bonnet fl ange (7) over bonnet (2) and

down over the bonnet studs (8), align match

marks.

22. Install bonnet fl ange nuts (9) and fi nger-tight en.

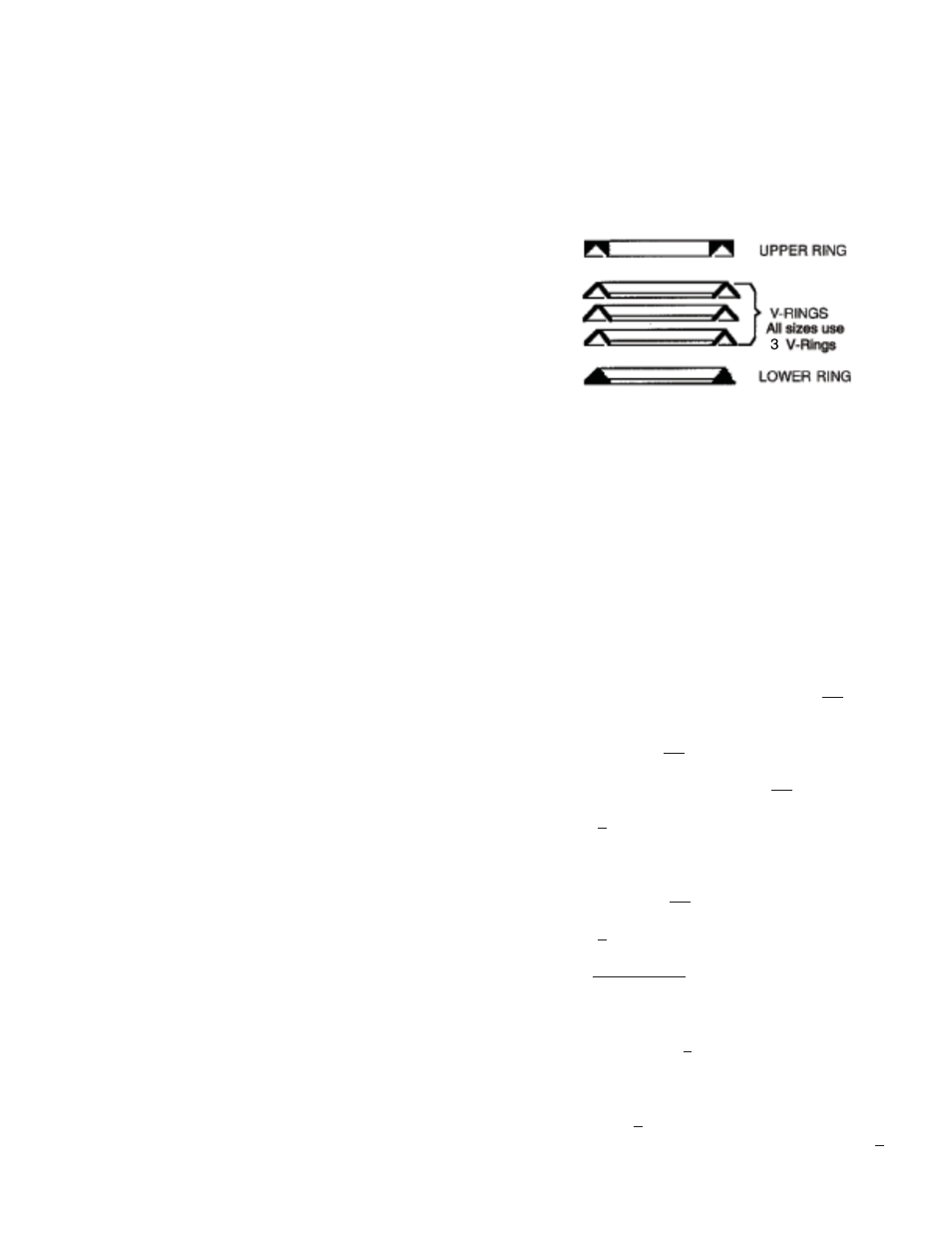

23. See Figure 5. Place a lower adapter packing

ring (10.1) over the stem-end (4) and press

it into the bonnet (2) packing box using the

pack ing follower (11). Repeat for the three

middle packing v-rings (10.2). Press upper

adapter ring (10.3) into the box; leave the

pack ing fol low er (11) in po si tion.

Packing Orientation

24. Wiggle stem (4) around to align parts

(2,3,4,7,10) as much as possible. Wrench-

tighten bonnet fl ange nuts (9) equally with a 1/4

turn revolution each, in alternating, cross-

pat tern. Using a torque wrench, tighten the

nuts (9) to 25 - 30 ft-lbs (33.8 - 40.6 N•m).

25. Using hand pressure, push plug/stem (4)

assembly down into the body (1) until the

plug touches the seating surface in the body.

Remove TFE tape from threaded end of

stem (4).

26. Raise Model C27or C53 actuator (AA) above

the threaded end of the stem assembly. Use

matchmarks from B.1. previous to assist with

(BA) and (AA) alignment.

27. Lower actuator assembly (AA) until the valve

stem (4) penetrates the opening in the yoke

(3). Re po si tion the “dangling parts” - packing

fl ange (23), yoke nut (15), ac ces so ry plate

((AP)) and in di cat ing washer (16) - over the

body stem (4). Con tin ue to lower the actuator

assembly (AA) until there is ap prox i mate ly

1/4" (6 mm) space between the two stems

(6) (4).

28. For ATC-FO: Connect a temporary air supply

hose that has an ad just able airset with gauge

to the ac tu a tor inlet to allow pres sur iza tion.

Slowly pressurize actuator to bring the ac-

tu a tor stem (6) to be with in 1/8" (3 mm) of

contacting the valve stem (4).

29. With hand lift stem (4) up to touch ac tu a tor

stem (6). Rotate valve stem (4) CCW (viewed

from above) to en gage w/ ac tu a tor stem (6).