Cashco 987 User Manual

Page 10

10

IOM-987

SECTION VII

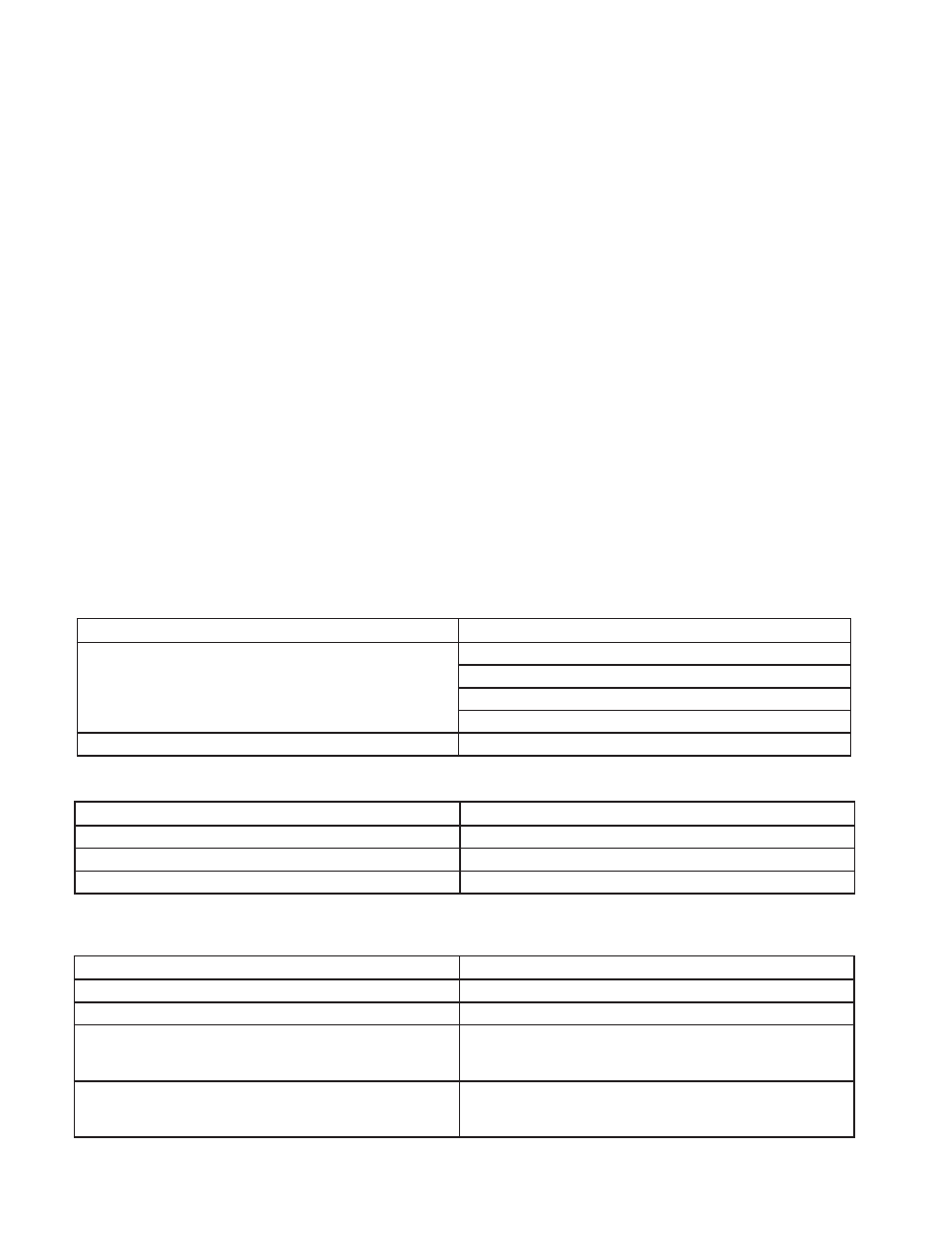

Possible Cause

Remedy

A. Excess packing friction.

A1. Realign body–stem–actuator.

A2. Packing follower too tight.

A3. Install Positioner.

A4. Increase bench.

B. Installed backwards.

B. Install per fl ow arrow.

Possible Cause

Remedy

A. Excess pressure drop.

A. Bring pressure drop within design limits.

B. Bushing wear.

B. Replace bushing and stem.

C. Misalignment.

C. Realign body-stem-actuator.

Possible Cause

Remedy

A. Excess pressure drop.

A. Bring pressure drop within design limits.

B. Bushing wear.

B. Replace bushing and stem.

C. Excessive cavitation in liquid service.

C1. Change operation parameters to relieve causes

of cavitation.

C2. Replace valve with valve equipped for cavitation control.

D. High outlet velocity.

D1. Reduce fl ow rate and/or pressure drop.

D2. Use multiple valves in series or in parallel.

D3. Increase outlet pipe size.

2. Valve makes "screeching" noise.

3. Valve exhibits "excess" vibration.

1. Valve is "jumpy" in stroking

VII. TROUBLE-SHOOTING GUIDE

NOTE: The proper calibration of the ac tu a tor/

valve unit will occur when at the upper pres-

sure level of bench setting, the valve plug (4)

will be in the "C" po si tion. At the lower level

of bench set the actuator pressure should be

within ± 8% of the lower bench setting for the

designed stroke length.

12. Release all pres sure from actuator.