Cashco Premier User Manual

Page 15

IOM-48

15

Benchset Range

Quantity

psig

(Barg)

of Springs

Array

5-15 (0.34-1.03)

6

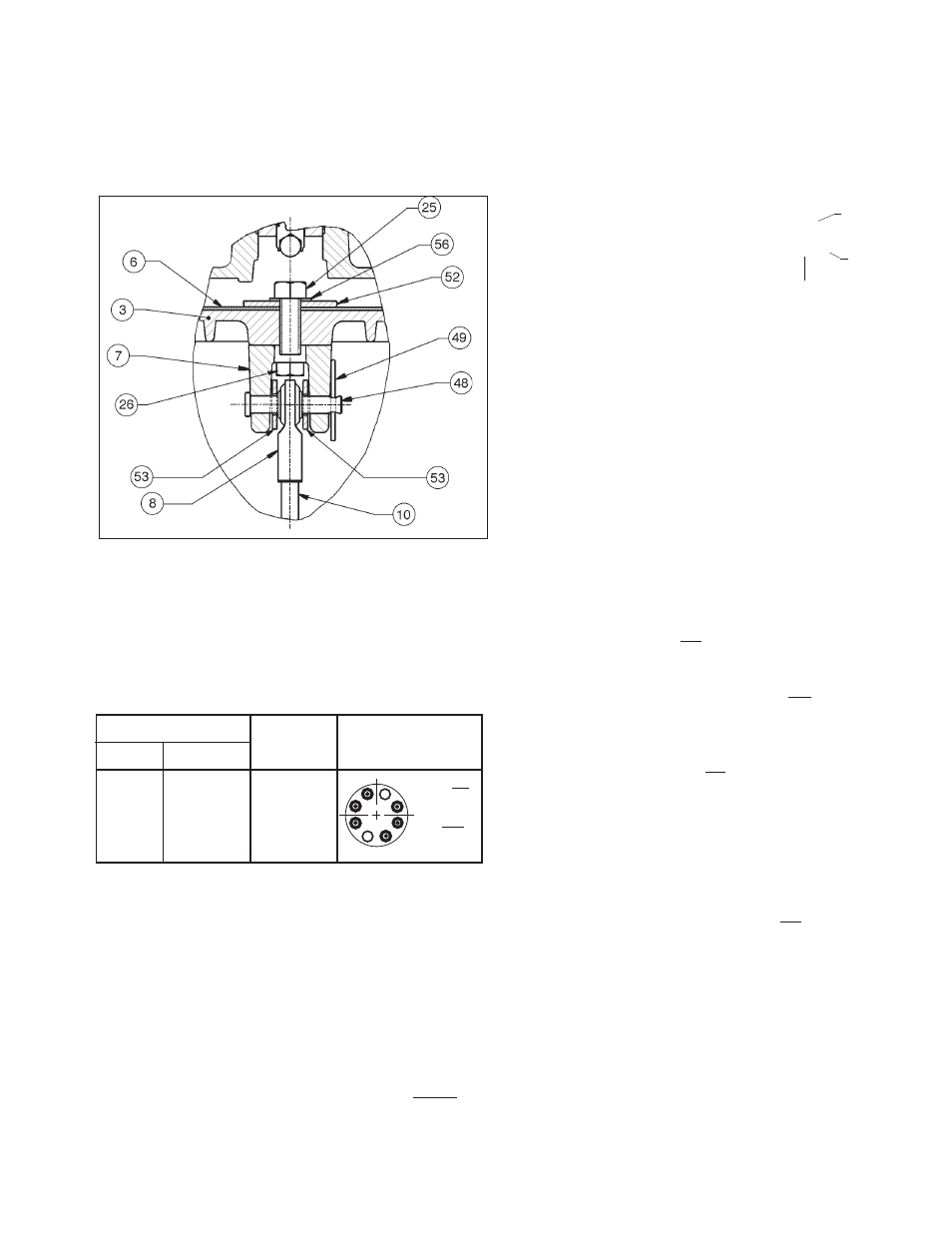

9. Inspect clevis (7), upper R.H. rod end (8), clevis

pin (48), washers (53) and hairpin (49) for signs

of looseness and/or wear; re place any worn

parts. Check bolting (26) for loose ness; tighten

as necessary to 15-18 ft-lbs (20-23 N-m).

Hub w/NO

Spring (11)

Hub With

Spring

(11)

Figure 12

Piston & Clevis Close-up

12. Reinstall a new diaphragm (6) and re as sem ble

the upper casing (1) as described in this Sec-

tion, V.E.12 through V.E.24.

13. Using air pressure of V.E.24., pressurize

the actuator upper casing (1) to the upper

value of the stated benchset range plus 2 psi

(0.14 Bar); i.e. for 5-15 psig (0.34-1.03 Barg)

benchset range, pressurize to 15+2 = 17 psig

(1.03+0.14 = 1.17 Barg). This pressure level

should cause the piston’s (3) lower skirt-edge

to bottom out on the lower casing (2).

14. Using only tools (i.e. no fi ngers within arm

housing (4)) to grasp the actuator stem/push

rod (10), insert push rod (10) with in ter con-

nect ed parts (9) (43) (43) (44) (54) into arm

housing (4) and engage into dangling upper

R.H. rod end (8) by rotating CW (viewed from

lower L.H. rod end (9)). Count number of

revolutions of push rod (10) en gage ment to

match those recorded in Article 4., previous,

at removal.

15. Release all air pressure into actuator upper

casing (1); remove air source from 1/4" FPT

connection.

16. Join the actuator assembly (AA) to the body

assembly (BA) as described in this Section,

V.I.

I. Joining of Body Assembly (BA) to Actuator

As sem bly (AA):

1. Determine proper orientation of actuator

(AA)-to-body (BA) for the following consid-

erations:

•

failsafe

action

• installed piping orientation.

Reference Sub-sections V.C. and V.D. to see

sche mat ics of orientations available.

2. Position body assembly (BA) on a fl at work

surface. Orient such that the actuator as-

sem bly (AA) can be ori ent ed with the top of

the actuator upper casing (1) on topside; i.e.

man u al handwheel operator sub-assembly

(MHWO) stem (58.2) vertically oriented, if

supplied.

3. Using an overhead hoist, lift the actuator

as sem bly (AA) (with position indicator ap-

pa ra tus (13,14,15,16,17,31,31,34), lever arm

ap pa ra tus (5,5,12,40,46,50,50), end-of-shaft

10. Place range springs (11) back onto hubs of

lower casing (2) per following table:

NOTE: Every spring (11) has another spring (11) 180°

across/opposite.

11. Aligning matchmarks of Article 7. above,

re po si tion piston (3) back onto top side of

range spring (11) array. Using a mirror tool

and fl ashlight, look through the rect an gu lar

open ing in the lower casing (2) from within the

arm housing (4) to ensure that the piston (3)

hubs are centered within the ID of the range

spring (11) coil. It may be necessary to use

a tool to move the upper end of the range

spring (11) as necessary to be “captured” by

a piston (3) hub. Each spring (11) MUST be

captured by a hub on top and bottom ends.