Gardner Bender CO2 CONDUIT FISHING SYSTEMS User Manual

Page 6

2. Unfurl the Inflatable line carrier and place it in the conduit-bag

portion first (Refer to Figure 8).

3. In large conduit (4, 5, and 6” diameter), it may be necessary to

point the seal-off nozzle at the plastic sleeve of the Inflatable

to achieve initial inflation. This is accomplished by tilting the

seal-off in the conduit entrance. Otherwise the collapsed

Inflatable may allow the small diameter stream of CO2 to blow

past it.

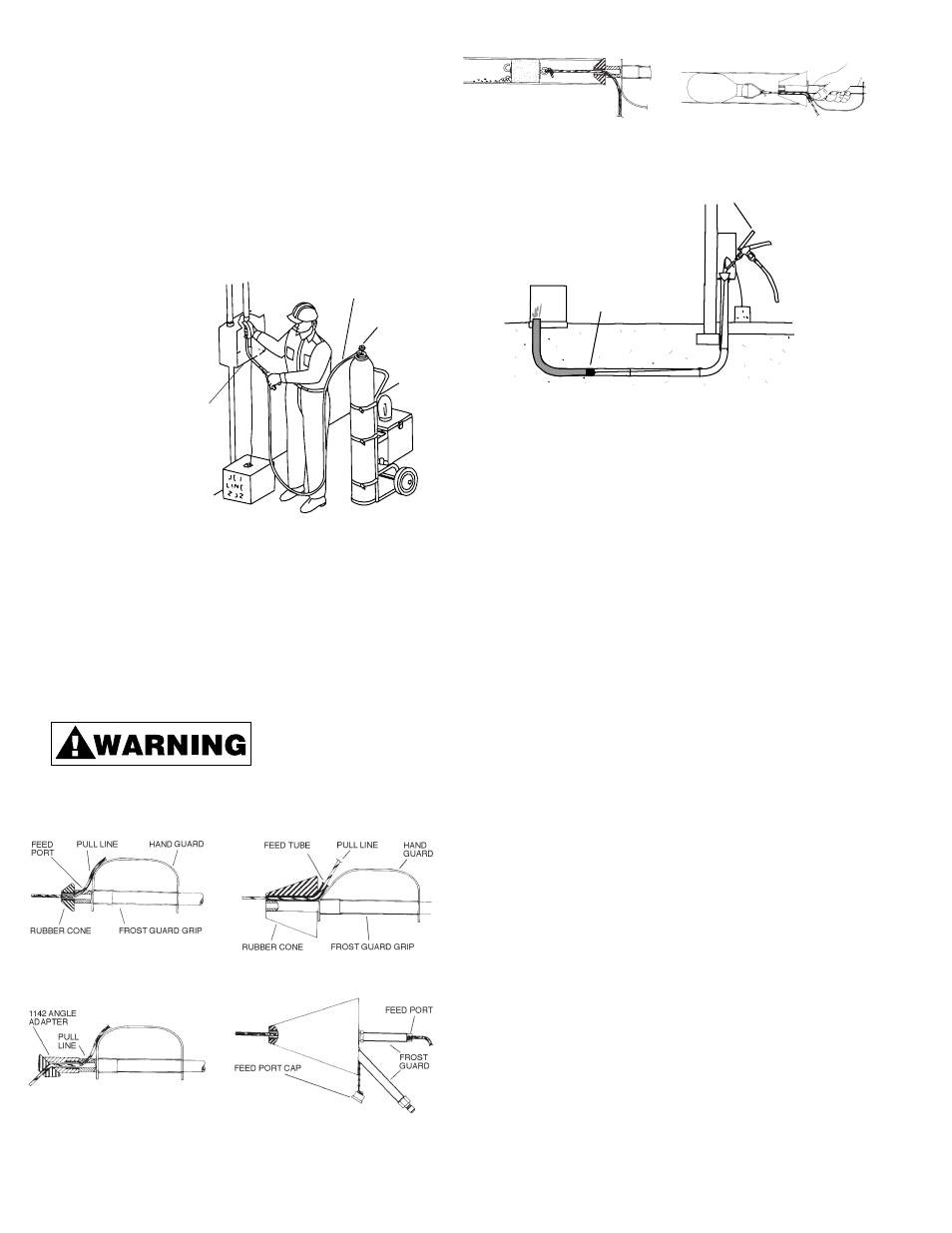

BLOWING PULL LINE IN THE CONDUIT

All CO

2

systems may be used to blow pull line or nylon line in the

Conduit. Position cart

transported cylinder

and pull line in a loca-

tion that will allow good

access to the conduit

entrance (Refer to Fig-

ure 9).

Set up as follows:

1. Connect the 1105

Operating Valve and

hose assembly cou-

pling nut to the CO

2

cylinder valve.

Hand tight is suffi-

cient for a good

seal.

2. Open the CO

2

cylinder rotary valve one or two turns is suffi-

cient to pressurize the hose up to the operating valve.

3. Connect the seal-off to the operating valve and make a prelim-

inary operating valve adjustment for moderate flow of CO

2

.

This is accomplished by backing out the operating valve han-

dle regulating screw and operating the valve until the desired

flow of CO

2

gas is obtained (Refer to Figure 9).

Always maintain a firm grip

on the seal-off hose frost

guard to prevent it from whip-

ping around while making this adjustment and discharging CO

2

.

4. Disconnect the seal-off from the operating valve while thread-

ing pull line through the feed port and attaching the line

carrier.

5.

Thread the pull line through the seal-off feed

port (Refer to Figures 10, 11, 12 and 13).

6. Tie the pull line securely to the line carrier to prevent loss in

the conduit (Refer to Figures 14 and 15).

7. Re-connect the seal-off to the operating valve and insert the

line carrier in the conduit.

8. Hold the seal-off hose frost guard, force seal-off firmly into the

conduit entrance and squeeze the operating valve to start the

flow of CO

2

. Continue the flow of CO

2

until the line carrier

comes out the other end of the conduit. This should take

approximately 20 to 30 seconds in a clear 3” or 4” duct that is

300 ft. long. If the duct contains water as shown in Figure 16,

the run time will be longer.

REFILLING THE 5 LB CYLINDER

To refill a 5 Ib. cylinder from a 50 Ib. cylinder, invert the 50 Ib.

cylinder sufficiently to

allow the CO

2

liquid to

flow to the top of the

valve end of the cylin-

der. The liquid in the 50

Ib. cylinder must cover

the valve so that it will

drain to the 5 Ib. cylin-

der, otherwise the 5 Ib.

cylinder will be filled

only with CO

2

gas.

Weigh the empty 5 Ib.

cylinder before begin-

ning the refill opera-

tion. Refer to step 9.

1.

Invert the 50 Ib. cylinder to an angle of approximately 30°

with the valve end down. Make sure the 50 Ib. cylinder is

held securely to prevent rolling or sliding and damage to the

cylinder valve.

2.

Attach the threaded hex nut on the RV5 Refill Connector to

the 50 Ib. cylinder valve. Finger tight is sufficient.

6

1105 OPERATING VALVE

AND HOSE ASSEMBLY

CYLINDER

ROTARY VALVE

Figure 9

Blowing Pull Lines in Conduit

Figure 10

1215 Seal-Off for

1

/

2

",

3

/

4

", 1", and 1

1

/

4

"

Conduit

Figure 11

1215 Seal-Off with 1142 Angle

Adapter

Figure 12

1216 Seal-Off for 1

1

/

4

" to 2

1

/

2

" Conduit

Figure 13

1206 Seal-Off for 1

1

/

2

" to 6" Conduit

Install on port

when flushing out

conduit or when blowing

Tag-Along line packages

Figure 14

Pull Line Attached to Foam Line

Carrier

Figure 15

Pull Line Attached to the Inflatable

Line Carrier

FOAM LINE CARRIER

1105 OPERATING VALVE AND HOSE

ASSEMBLY WITH 1206 SEAL-OFF

Figure 16

Water Being Pushed Ahead of Foam Line Carrier

Figure 17

Refilling the 5 Lb. CO

2

from the 50 Lb. Cylinder

SEAL-OFF