Gardner Bender CO2 CONDUIT FISHING SYSTEMS User Manual

Page 5

Connection to the 20 Ib. or 50 Ib. CO

2

cylinder rotary valve is

made with the special thread coupling nut and O-ring face seal

on the hose stem. The coupling nut screwed hand tight on the

valve port is all that is required for a good seal. When the cylinder

rotary valve is opened (opening one or two turns is sufficient) the

hose is pressurized up to the operator held hand valve.

Any of the GB/Jet Line CO

2

seal-offs may be threaded up with

pull line and line carrier and then connected to the operating

valve quick coupling. An adjusting screw is provided on the oper-

ating valve handle to limit the valve travel and regulate the flow of

CO

2

gas as required by the user.

When not in use, disconnect the seal-off from the operating

valve, close the cylinder rotary valve, operate the operating valve

to depressurize the hose and remove it from the cylinder valve.

Store the hose on the cylinder cart hose hanger hooks or in the

cart tool box.

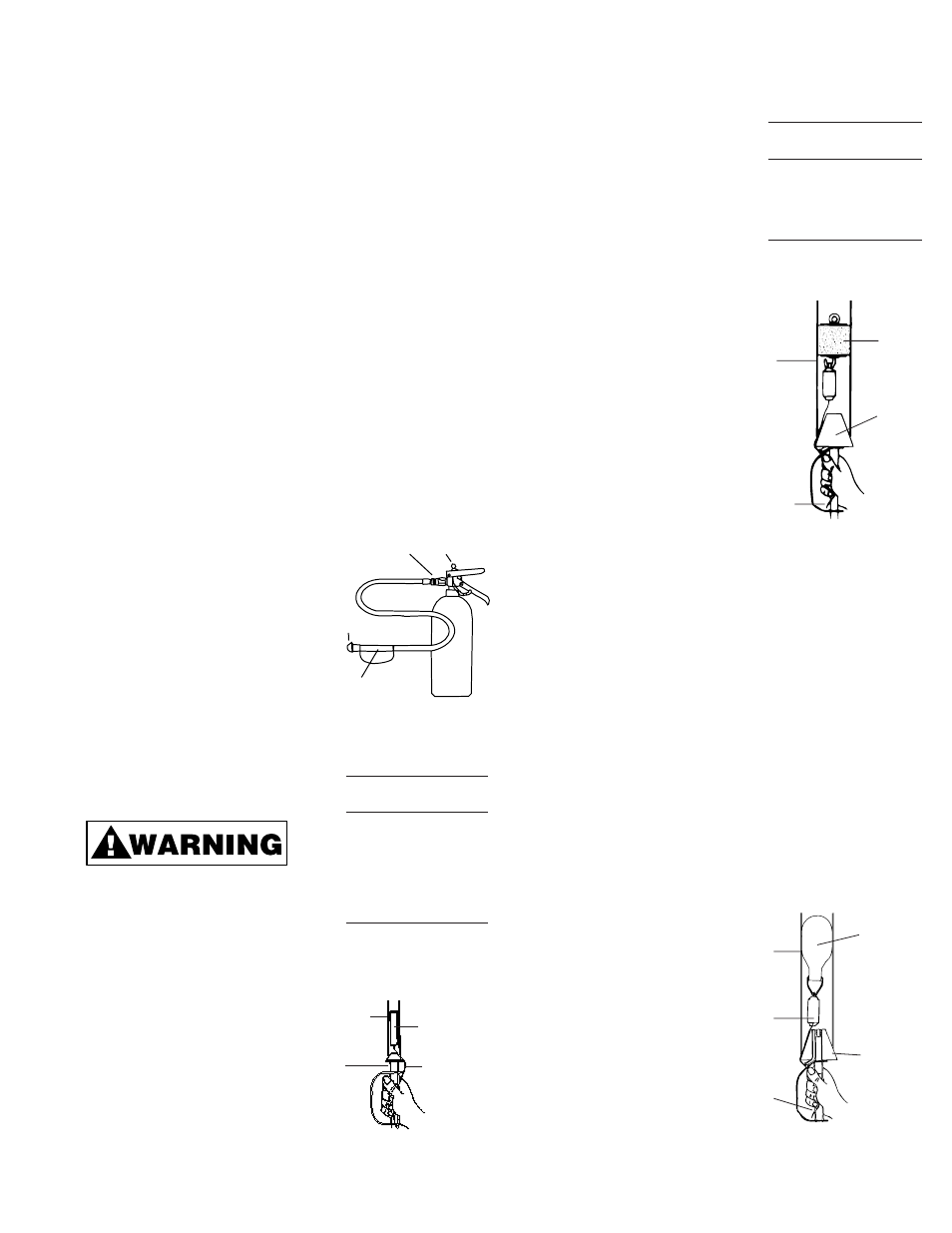

Model 1142 Angle Adapter (See Figure 11) – The 1142 Angle

Adapter is provided for use with the 1215 seal-off for installing

line in small junction boxes and hard-to-get-to conduit.

To use, remove the rubber cone on the 1215 seal-off and screw

the angle adapter on the threaded end of the brass feed through

fitting.

Always maintain a firm grip on the seal-off hose behind the feed

through fitting to counteract the recoil force of the high velocity

CO

2

gas.

Blowing Line Packages through

Conduit – This is the easiest

method of placing a light weight pull

line in the conduit. The line package

or seal-off requires no thread up for

this operation. However, it is recom-

mended that the seal-off be connect-

ed to the operating valve and a pre-

liminary CO

2

flow adjustment be

made by alternately operating the

valve and adjusting the regulating

screw. If more CO

2

flow is required,

back out the regulating screw one

or two more turns (Refer to Figure 4

and 5).

Always maintain a firm grip on the

frost guard of the seal-off hose to

prevent it from whipping around.

Power Saver Line Package –

Select the Power Saver line pack-

age for size and length of line to fit

up to 1” diameter conduit. It is

recommended that you flex the

package back and forth two or

three times to loosen it prior to its

use. This will make the line easi-

er to dispense.

Proceed as follows:

1. Pull out approximately two

feet of line. Hold on to this trail-

ing end to prevent its loss in the

conduit.

2. Insert the line package in the conduit-foam tip first.

3. Hold the seal-off hose frost

guard, force rubber cone firmly in

the conduit entrance and give the

line package two or three quick

spurts of CO

2

. The package

should be blown through the con-

duit trailing a line as it goes

(Refer to Figure 6 and Table 1).

4. It is recommended that

the ends of the line be

tied off until ready for use

to prevent the end from

being accidentally pulled

back into the conduit.

Tag-Along Line Package -

Tag-Along Line Packages

perform the same function

as Power Saver line pack-

ages except they are used

in 1

1

/

4

” diameter and larger

conduit. Tag-Along pack-

ages must be used with a

line carrier to supply the

pulling force.

Select the Tag-Along Line

Package and a line carrier

either foam or inflatable that fits the conduit diameter and pro-

ceed as follows:

1. If a foam line carrier is selected, attach the Tag-Along pack-

age plastic eye to the foam line carrier hook. Pull out approxi-

mately two feet of line and hold on to the trailing end (Refer to

Figure 7).

2. Insert the foam line carrier and Tag-Along package in the

conduit.

3. Hold the seal-off hose frost guard, force rubber cone firmly in

the conduit entrance and squeeze the CO

2

operating valve

handle. Continue to apply a flow of CO

2

until line carrier

comes out the other end of the conduit. The run time will be

longer than for the Power Saver line package because of the

larger conduit and greater volume of CO

2

required. However,

the run time in 3” and 4” conduit 200 and 300 feet long should

be completed in a matter of seconds (Refer to Figure 7).

4. Tie off the ends of the

line to prevent it from

being accidentally

pulled into the conduit.

Inflatable Line Carrier

1. Select an Inflatable line

carrier within its conduit

diameter range and

attach the Tag-Along

Line Package to the

wire bail. Pull out

approximately two feet

of line and hold on to

the trailing end.

5

Figure 6

Blowing a Power Saver Line

Package In Conduit

Conduit

Length

Model

Dia.

Ft.

LP2150

1

/

2

”

150’

LP3200

3

/

4

”

200’

LP3300

3

/

4

”

300’

LP3450

3

/

4

”

450’

LP4200

1”

200’

LP4300

1”

300’

LP4450

1”

450’

Table 1

Power Saver Line Packages

CONDUIT

1215

SEAL-OFF

POWER SAVER

LINE PACKAGE

TRAILING END

OF LINE

Figure 7

Blowing a Foam Line Carrier and

Tag-Along in Conduit

FOAM

LINE

CARRIER

1216

SEAL-OFF

TRAILING

END OF LINE

CONDUIT

Length

Strength

Model

Ft.

Lbs.

LP2206T

400

22

LP2208T

600

22

LP2207T

800

22

LP1704T

1200

22

LP1705T

600

50

Table 2

Tag-Along Line Packages

Figure 8

Blowing an Inflatable Line Carrier and

Tag-Along in Conduit

THE

INFLATABLE®

LINE CARRIER

1216 SEAL-OFF

CONDUIT

TAG-A-LONG

LINE PACKAGE

TRAILING

END OF LINE

LOCK BALL

COUPLING

REG ULATING

SCREW

1215 SEAL-OFF

FROST GUARD

GRIP HERE

Figure 5

1103N Cylinder with 1215

Seal-Off Connected