Gardner Bender CO2 CONDUIT FISHING SYSTEMS User Manual

Page 4

BLOWING LINE IN THE CONDUIT

The GB/Jet Line CO

2

system is designed to blow a line in

“sealed” conduit such as EMT with compression type couplings,

rigid conduit, and plastic conduit with adhesive bonded joints.

These types of conduit generally require very little effort to install

a pull line with the CO

2

system.

There are some conduit runs that will be difficult or impossible to

blow a line in with the CO

2

system, such as:

• Conduit containing hard packed sand, silt, debris, or concrete.

• Conduit with separated joints.

• Conduit with two sizes of duct connected by a reducer coupling.

• Conduit with unsealed set screw couplings.

• Small diameter conduit of several hundred feet with multiple

bends.

PREPARATION

It is helpful to know the purpose for which a line is to be used

once it has been blown into the conduit. This will aid the user in

selecting the appropriate line for the job.

Knowing the approximate length of the conduit will prevent

selecting a line that is too short for the run; i.e., if the user wishes

to place a light line in a

3

/

4

” conduit with an estimated length of

195 to 200 feet, a 300 ft. power saver line package should be

selected for the run. An alternate solution would be to use a

3

/

4

”

foam line carrier pulling bulk nylon line. Either selection would

insure an adequate length of line.

Selecting the Pull Line – The following list is presented as a

guide in selecting a pull line. Users must determine for them-

selves which best fits their needs.

1. Identification of a conduit run termination where multiple con-

duit runs originate at a single location.

Recommended Line: Power Saver Line Packages or Bulk

Nylon Line.

2. Placing a line in the conduit for use at a later date.

Recommended Line: Small conduit

1

/

2

”,

3

/

4

”, and 1” Power

Saver Line Packages, Bulk Nylon Line or PL232. Larger con-

duit 1

1

/

4

” through 6” Tag-Along Line Packages, PL Series

Line PL232, PL235, and PL2310.

3. Pulling in a larger line, rope or steel winch cable.

Recommended Line: Small conduit

1

/

2

”,

3

/

4

” and 1”. Same as

2 above. Larger conduit PL232 or PL235.

4. Pulling wire in conduit.

Recommended Line: PL232, PL235, and PL2310.

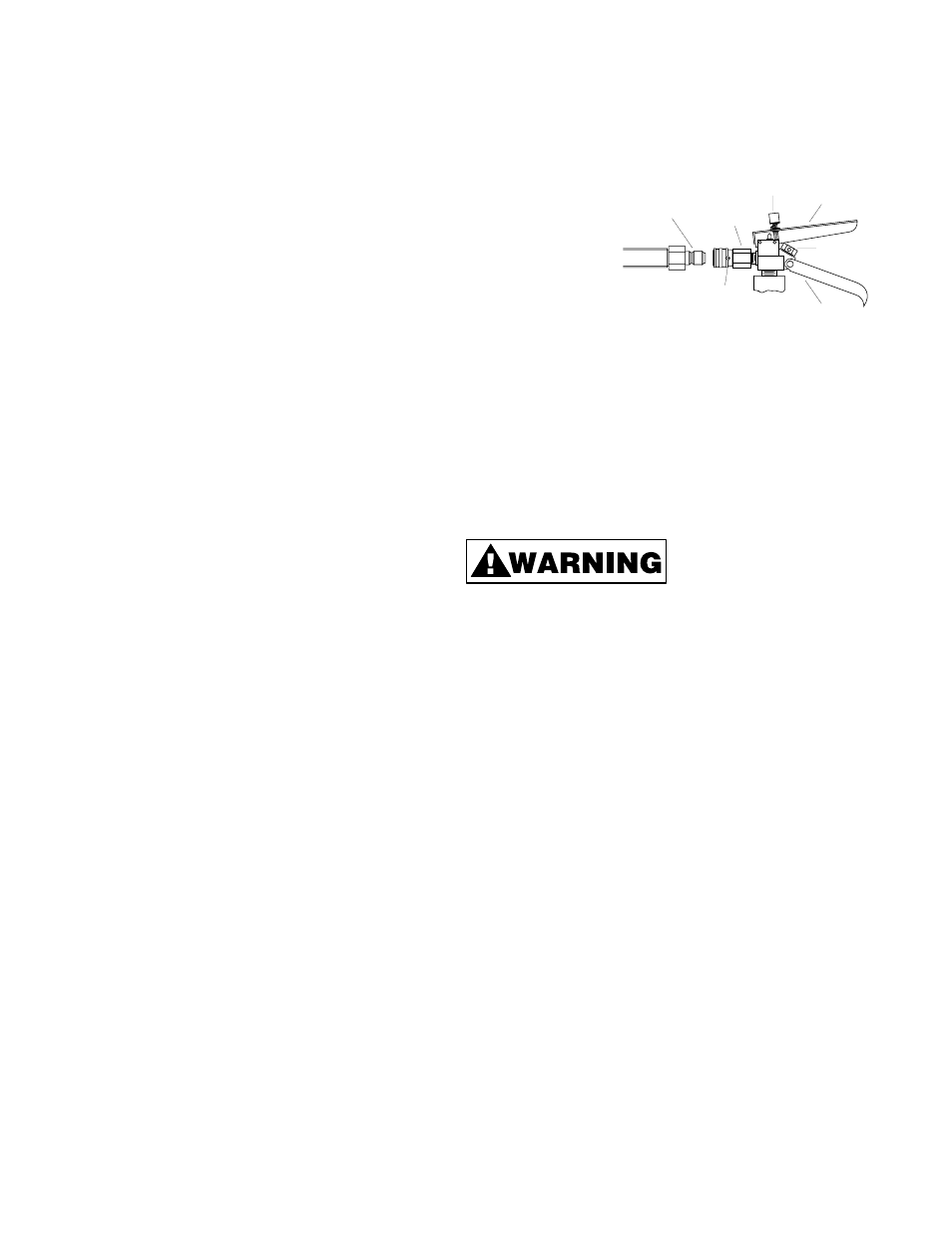

SEAL-OFFS

Seal-offs provide a means of making the final connection

between the CO

2

operating valve and the conduit, as well as pro-

viding a means of feeding pull line into the conduit. The tapered

rubber cone that forms the seal at the conduit entrance must be

held firmly in the conduit when flushing out water and debris or

blowing line in the conduit. Be sure to keep a firm hold on the

seal-off hose frost guard while operating unit.

All CO

2

seal-offs are equipped with a male quick disconnect plug

that plugs into the operating valve ball lock coupling on the 5 Ib.

CO

2

cylinder valve or the 1105 operating valve and hose assem-

bly used with the 20 Ib. and 50 Ib. CO

2

cylinders (Refer to

Figure 4).

Connect the seal-off to the 5 Ib. CO

2

cylinder valve or the 1105

operating valve as fol-

lows:

1. Rotate the valve ball

lock coupling sleeve

to align notch with

embedded ball

(Refer to Figure 4).

2. Retract the ball lock

sleeve.

3. Plug in seal-off connector.

4. Release the sleeve to lock coupling.

5. Rotate sleeve notch away from embedded ball to prevent acci-

dental disconnection.

Disconnect the seal-off from the CO

2

operating valve when

threading pull line through the feed port and attaching a line carri-

er. This step will make the preparation job easier and eliminate

the possibility of accidental discharge of CO

2

.

Always maintain a firm grip on

the seal-off hose frost guard

when the seal-off is connected

to the operating valve (See Figure 5). This will prevent the free

end from whipping around while discharging CO

2

.

Model 1215 Seal-Off – The 1215 Seal-Off with two foot hose is

designed for use with the 5 Ib. CO

2

cylinder for blowing line in

3

/

4

”,

1

/

2

”, 1”, and 1

1

/

4

” conduit. This seal-off is required for blowing

power saver line packages in

1

/

2

”,

3

/

4

”, and 1” conduit. The 1215

seal-off works equally well with the larger GB/Jet Line 20 and 50

Ib. systems when connected to the 1105 CO

2

operating valve

and hose assembly.

The feed through port will accept bulk nylon line and pull line up

to

1

/

8

” diameter.

Model 1216 Seal-Off – The 1216 Seal-Off with two foot hose is

similar to the 1215 except for a larger sealing cone. It may be

used in conduit sizes 1

1

/

2

” through 2

1

/

2

” diameter and with pull

line up to

1

/

8

” diameter.

Model 1206 Seal-Off – The 1206 Seal-Off is designed for use

with the larger GB/Jet Line 20 and 50 Ib. CO

2

systems. It must be

used with the 1105 operating valve and hose assembly. The

large rubber cone will fit conduit sizes 1

1

/

2

” through 6”. The feed

through port will accept all GB/Jet Line PL Series pull lines

PL232, PL235, and PL2310.

OPERATING ACCESSORIES

GB/Jet Line provides specially designed easy-to-use operating

accessories for the CO

2

systems that meet most conduit fishing

needs.

Model 1105 Operating Valve and Hose Assembly – The 1105

operating valve and 12 ft. hose assembly connects to the 20 or

50 Ib. CO

2

cylinder and allows the operator a wide range of

movement to reach hard-to-get-to conduit runs.

4

RETAINING NUT

& SAFETY DISC

OPERATING

HANDLE

REGULATING SCREW

BALL LOCK

COUPLING

SEAL-OFF FITTING

MALE PLUG

SLEEVE NOTCH &

EMBEDDED BALL

CARRY HANDLE

Figure 4

Operating Valve and Seal-Off Coupling