Gardner Bender B2000 Series G Cyclone Bender User Manual

Page 3

6.

When bending

1

⁄

2

" - 1" conduit the upper roller and support

arm must be positioned between the shoe and the roller

housing. Position the urethane roller by moving the roller

housing against the frame stop and removing the pin.

7.

Lift the roller support arm to clear the nylon rollers and

swing the arm (toward shoe) over the roller housing.

Lower the arm into the support bracket and insert the ring

pin. See Figure 4.

Figure 4. Position Roller Support

8.

Insert the conduit in the shoe groove marked with the

number matching the size conduit being bent. The conduit

must set in the shoe and in the jaw. The end of the conduit

must extend a minimum of 2" beyond the jaw. See Figure

3. Refer to table A or B on page 5 for bending data.

9.

Each time a different size and type of conduit is being

bent, three facts must be determined and set into the

bender shoe control system. The required settings are:

conduit size, material and desired bend angle. Prior to

setting, be sure the desired size indicator scale is toward

the operator and the correct shoe grooves are also toward

the operator.

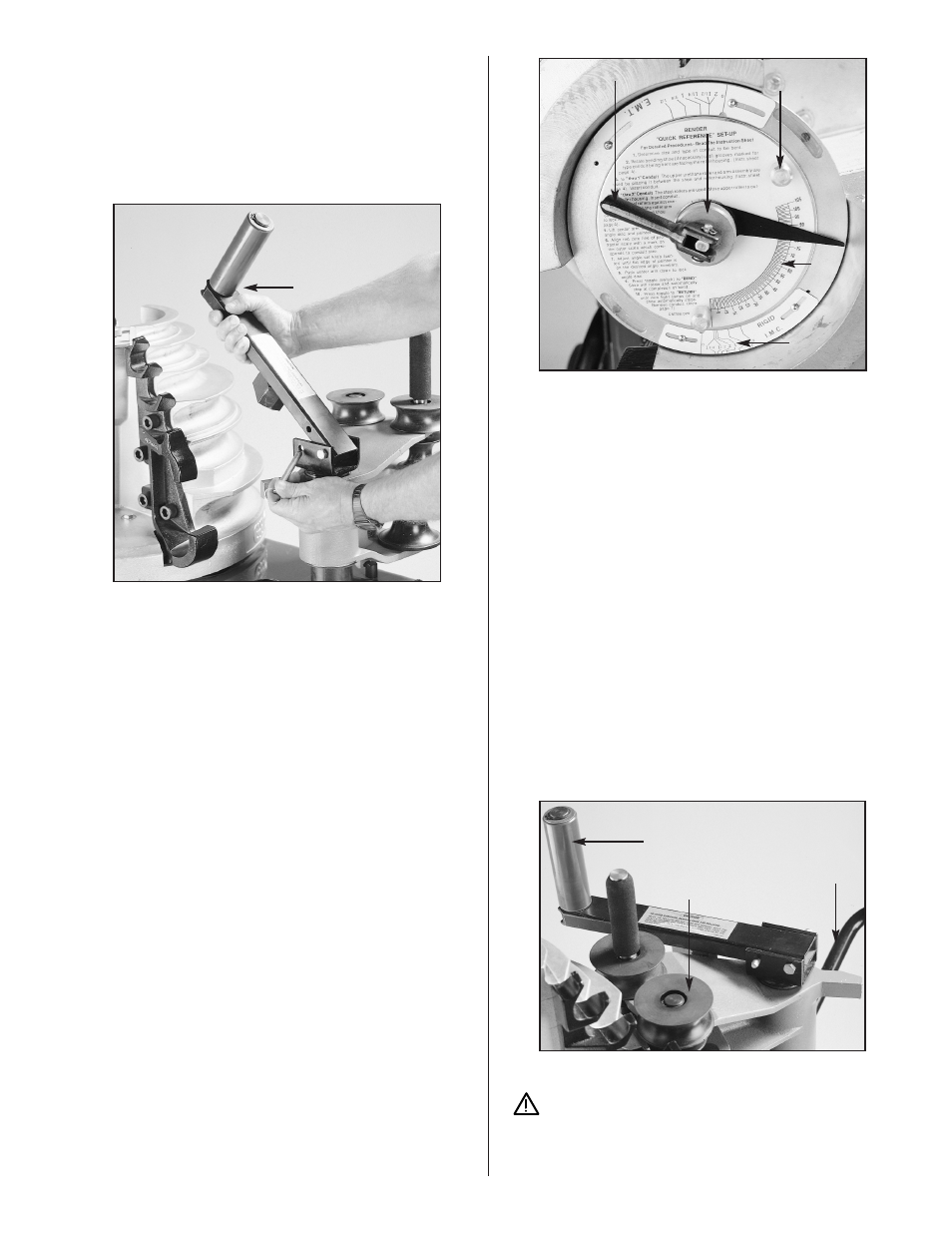

a.

Lift the locking handle. See Figure 5. Use the two

small pins to rotate the angle disc, clockwise, until the

red zero line is directly in line with the zero line on the

size scale.

b.

Set the bender for specific conduit size by turning the

angle disc until the red line is on the size indicator

mark which matches the size conduit being bent. Be

sure the correct size scale is being used (EMT, lMC,

or Rigid).

c.

Move the bend angle set knob (See Figure 5) until the

flat edge of the pointer is on a line indicating the exact

degree of bend desired. Lower the center arm to lock

the pointer and scale and to prevent inadvertent

movement during bending.

Figure 5. Set Angle Scale

10. Activate the bending shoe by holding the pendant control

toggle switch in the “Bend” position. The shoe will rotate

until the angle set on the pointer is reached.

11. To remove the conduit, hold the toggle switch in “Return”.

The shoe will return to the start position and stop

automatically. The zero set light will come on. Bending

more conduit of the same type and size is accomplished

by loading conduit and pressing the toggle switch.

4.2 Bending 1

1

⁄

4

", 1

1

⁄

2

" and 2" Conduit

NOTE: All operations referring to “toward the operator” are

viewed from the lifting handle end of the bender frame.

1.

Bending 1

1

⁄

4

" through 2" requires using one of the three

sets of nylon rollers and one of the grooves on the lower

half of the bending shoe.

2.

Move the roller housing against the frame stop. See

Figure 10. The upper urethane roller must be on the

outside (toward frame handle) of the roller housing. See

Figure 6. If it’s not, pull the ring pin. Lift the roller support

arm, swing it over the roller housing, lower the handle into

the bracket and insert the ring pin.

Figure 6. Position Roller Support

CAUTION: To avoid damage to the bending shoe,

always place the roller housing against the frame stop,

prior to activating the bending shoe.

3

Roller Support Arm

Locking Handle

Angle

Disk

Size Scale

Angle

Set Knob

Rotating Pins

Frame Handle

Nylon Rollers

Upper Urethane Roller