Gardner Bender B2000 Series G Cyclone Bender User Manual

Page 2

NOTE: All operations referring to “toward the operator”

are viewed from the lifting handle end of the bender frame.

3.0 SPECIFICATIONS

Power Source .....................................120 V 60 cycle AC

Pendant Control Circuit ......................12 VDC

Motor ..................................................1 HP 100 V 60 cycle DC

Weight ................................................345 lbs.

Height .................................................38 inches

Width ..................................................31 inches

Length.................................................45 inches

Circuit Breaker....................................15 Amp

Bend Capability ..................................

1

⁄

2

" - 2" IMC, EMT

Rigid Steel or

Rigid Aluminum

4.0 OPERATION

4.1 Bending

1

⁄

2

",

3

⁄

4

" and 1" IMC, EMT and

rigid conduit:

1.

Position the bender in a level dry area large enough to

permit loading and unloading various lengths of conduit.

Position the frame, either horizontally or vertically, by

pulling the spring loaded pin on the side of the bender

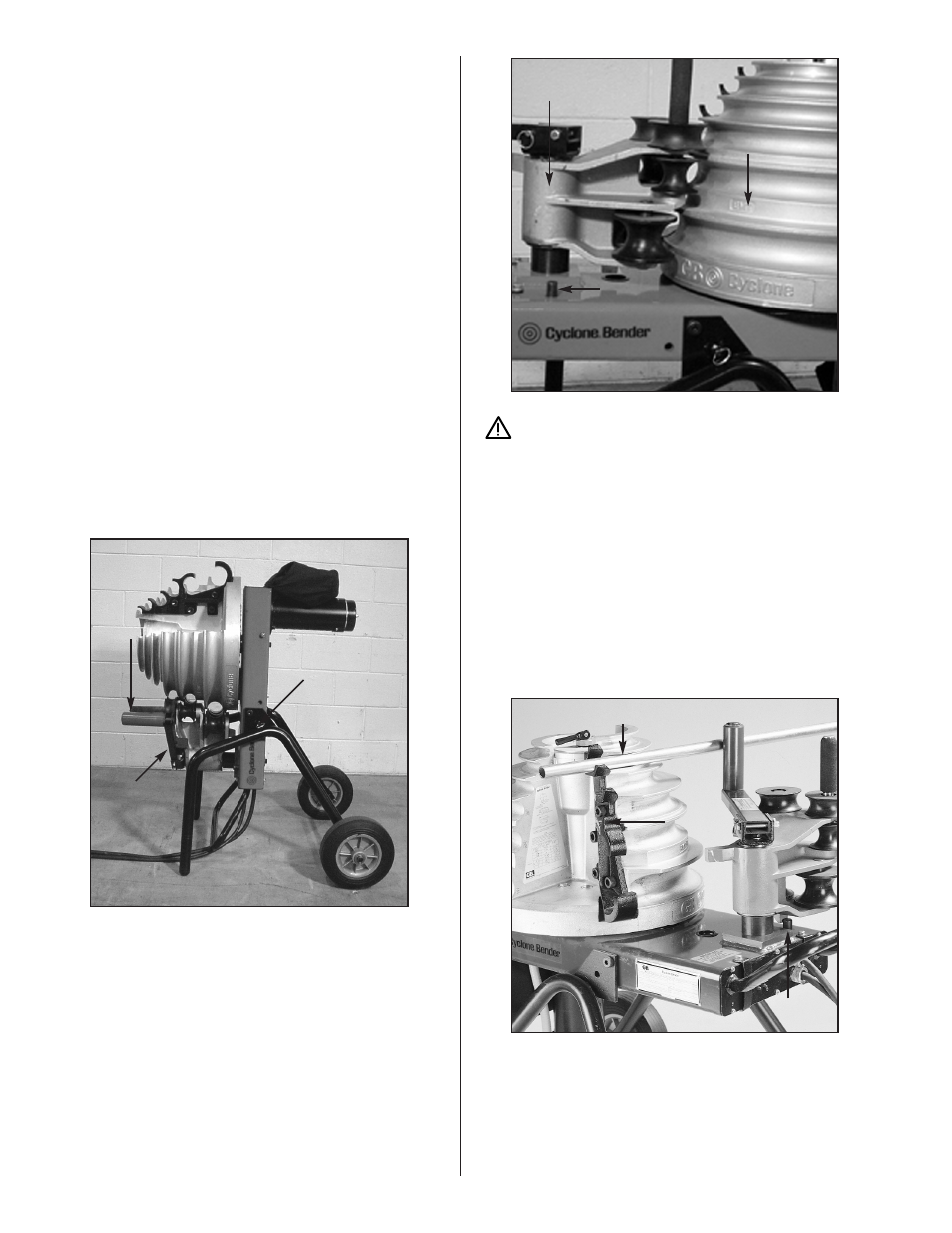

frame. See Figure 1.

Figure 1. Vertical Position

2.

Identify the type (IMC, EMT or Rigid) and size conduit to

be bent.

3.

Locate the markings that indicate which grooves are used

for specific materials, and which grooves are used for

specific size conduit. See Figure 2.

Figure 2. Set Up

CAUTION: To avoid damaging the rollers and roller

housing, always place the roller housing against the

frame stop prior to rotating the shoe.

4.

Push the roller housing against the frame stop.

See Figure 2. Rotate the shoe to bring the required

grooves (EMT, IMC or Rigid) facing toward the operator.

To activate the shoe, hold the pendant toggle switch in

“Return” and press the jog button until the zero light goes

out. The shoe will rotate and stop in the load position. The

zero light will come on.

5.

The upper urethane roller and support arm (See Figure 3)

is used for bending

1

⁄

2

" through 1" conduit. One of the

top three shoe grooves will be used, depending on

conduit size.

Figure 3. Bending 1/2" - 1"

2

Support Arm

Positioning Pin

Upper Roller

Roller Housing

Frame Stop

Material Identifier

Frame Stop

Jaw

Bend Groove