Fluid Components International FS10 Button Setup Quick Guide User Manual

Page 2

Fluid Components International LLC

06EN003398 Rev. B

Bank Selection of Stored Parameters

The FS10A has 7 storage banks. Banks 1-6 are factory set defaults of common applications or specific factory calibrations. Bank 7 is available for

user saved parameters. Bank 0 is always the “operating” bank. Function 4 is used to move parameters from a selected bank to operational Bank 0.

Function 15 is used to store new field set-up parameters into Bank 7 for future retrieval.

Un-calibrated units are shipped with default parameters from Bank 1 active in the 0 Bank. The parameters permit operation over the entire range of

the meter as it may be applied to any gas or liquid.

Recommended Set-up Order

1.

Scale the FS10A over the desired flow range — Adjustment of flow over useable range is recommended if possible. This span setting will be

reflected on the LEDs (1-10) as well as the 4-20 mA output (0% - 100%). If it is impossible to throttle the flow, it is recommended a span be

established initially with normal flow, then use the LEDs to set a trip-point below that value for low flow alarm. Dynamic Mode, FUNCTION 5,

automatically establishes the highest flow rate as the span and could be considered to aid in setup in these cases. Refer to Operating Manual

for complete instructions on using Dynamic Mode.

a.

Set the Zero using Button FUNCTION 6 (no-flow full tube is suggested in liquid service) to capture the zero point.

b.

Set the Span using Button FUNCTION 7. Capture this setting while simulating highest flow rate in the tube.

2.

Set the trip point using either method below:

a.

10% increment method, Button FUCNTION 1, allows setting against the 10 LEDs on the display. Each LED represents 10% of the flow

range established in 1. Flashing LED confirms value of trip point.

b.

Capture method, Button FUNCTION 2, allows setting the trip-point at precisely the flow rate through the tube at the time of capture.

Flashing LED indicates approximate value of trip point.

3.

Final adjustments

a.

Set Failsafe using Button FUNCTION 3; relay normally activated above trip point (default condition) or below trip point.

b.

Other settings are available through the buttons if required, including hysteresis, time delay and filtering. Refer to the Operating Manual

for complete descriptions. After all adjustments are finalized, the new settings now in operational Bank 0 may be saved to Bank 7, 8 or 9

using Button FUNCTION 15.

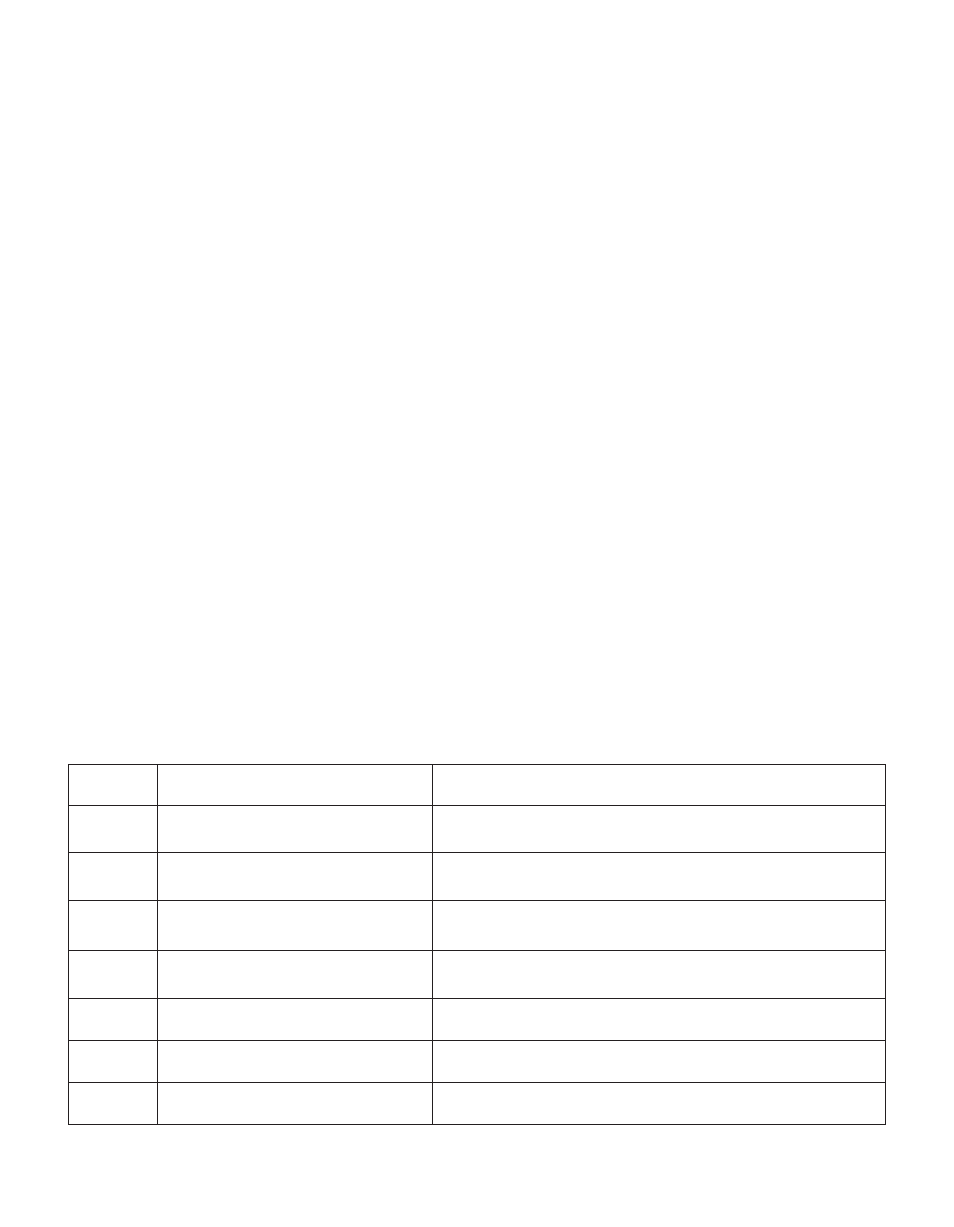

Bank Default Values

Bank No.

Process Fluid

Range Setting

0

FS10 Current Active Parameters

1

Universal Default Setting A - Low flow

sensitivity

Un-calibrated output - low sensor excitation power setting

Full range gas or liquid

2

Air/Gas -40 °F to 250 °F (1/4 ″ tube and SP76

adapter)

1 SFPS to 50 SFPS (200 cc/min to 10,000 cc/min, [0.4 SCFH to 20 SCFH] in

1/4 “ tube) – trend accuracy 10% full scale

3

Universal Setting B - High flow gas,

liquids

Un-calibrated output – 1.5X sensor excitation power setting

Full range liquid and gas

4

Water/Glycol -40 °F to 250 °F

0.02 SFPS to 0.5 SFPS (4 cc/min to 100 cc/min [0.001 GPM to 0.03 GPM] in

1/4” tube) – trend accuracy 10% full scale

5

Reserved for custom calibration

6

Reserved for custom calibration

7

User defined and stored