Sensing element installation, Control circuit installation, Wiring installation – Fluid Components International 8-66B_12-64B Series Manual Installation User Manual

Page 2

FLUID COMPONENTS INTL

CHAPTER 2 - INSTALLATION

Models 12-64/8-66 Basic Switch

2 - 2

Doc. No. 06EN003264 Rev. A

The above precautions are minimum requirements to be used. The complete use of ESD precautions can be found in

the U.S. Department of Defense Handbook 263.

Verify Installation Location

Prepare the vessel for installation, or inspect the already prepared location to ensure that the instrument will fit into

the system. Prepare the necessary sealants or gaskets to provide a leakproof installation for the application if

required. The location of the 12-64 that should have been prepared at the time of order should be at least 20 pipe

diameters downstream and 10 pipe diameters upstream from any bends or interference in the process pipe or duct to

achieve the greatest accuracy.

Sensing Element Installation

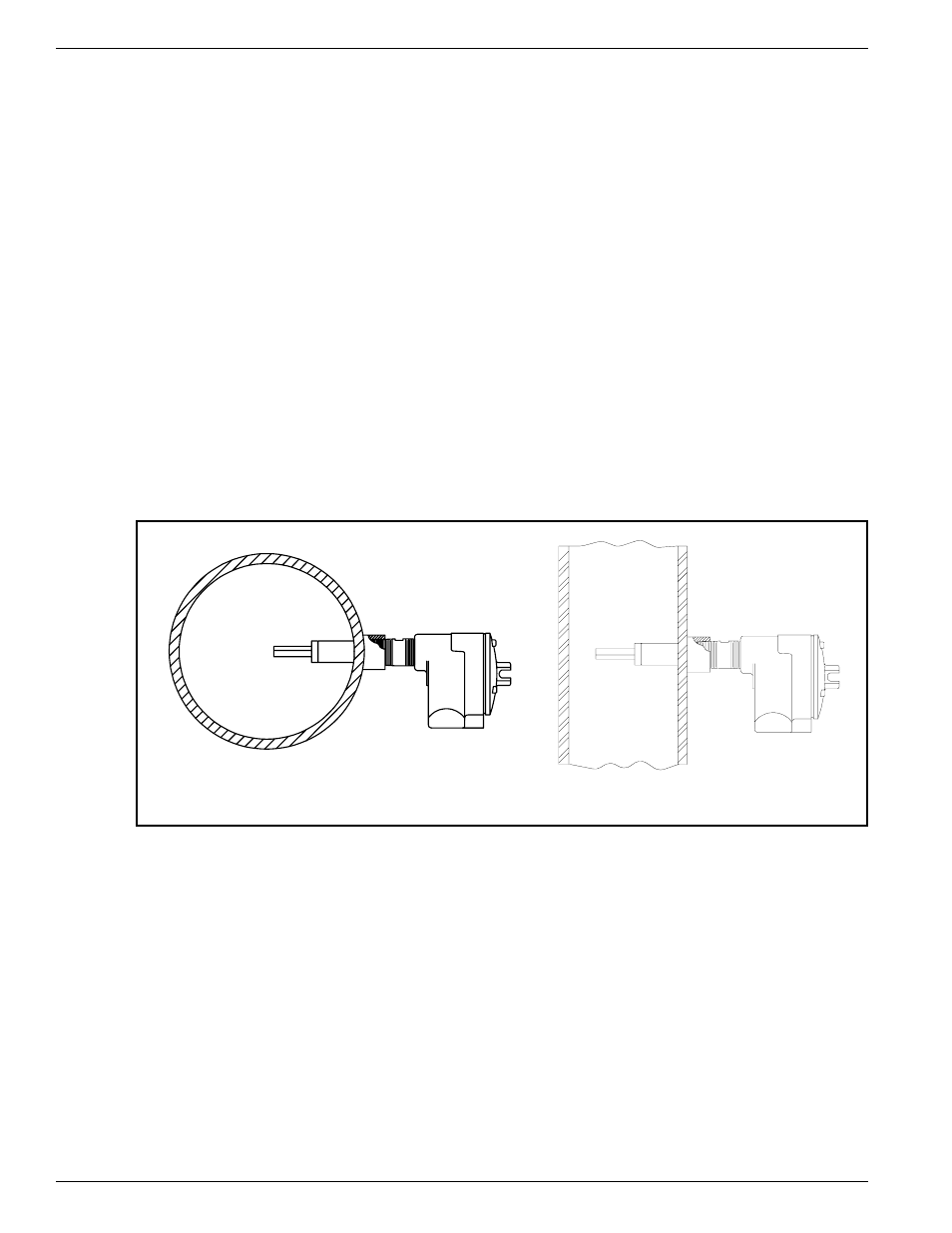

Install the sensing element in the process piping at the desired location. Verify that the flat area machined into the

sensing element is flat and level. If the flat is present it is machined on the sensing element near where it is screwed

into the enclosure. "FLAT UP & LEVEL" is also etched on the flat surface.

Apply a lubricant/sealant compatible with the process to all threads. Use a pipe wrench for 1-1/4 inch (32 mm) NPT

and larger connections, or an open-end wrench for 1-1/4 inch (32mm) NPT and smaller connections. All

connections should be tightened firmly. To avoid leaks, do not overtighten or cross-thread connections. The figures

in Appendix A and Figure 2-1, show this configuration.

If the sensing element is mounted in a downward direction, moisture build up in the enclosure needs to be avoided.

FCI recommends that an O-ring be used on the enclosure cover. In addition, attached conduits must be isolated by

using a conduit potting Y.

Figure 2-1. Sensing Element Threaded Mounting

Control Circuit Installation

The configuration of the instrument is with the control circuit already installed in the local enclosure (the control

circuit is physically mounted with the sensing element).

Wiring Installation

Conduit Routing

All socket and/or terminal block connections are to be made through the 1 inch female NPT openings in the

enclosure. FCI strongly recommends that all electrical cables be run through an appropriate conduit for the

protection of the instrument and personnel.

Protection of the control circuit from moisture is an important consideration. Keep the entry of the conduit into the

12-64 BASIC

8-66 BASIC

C00166-1

C00033-1