Burkert Type 8112 User Manual

Page 29

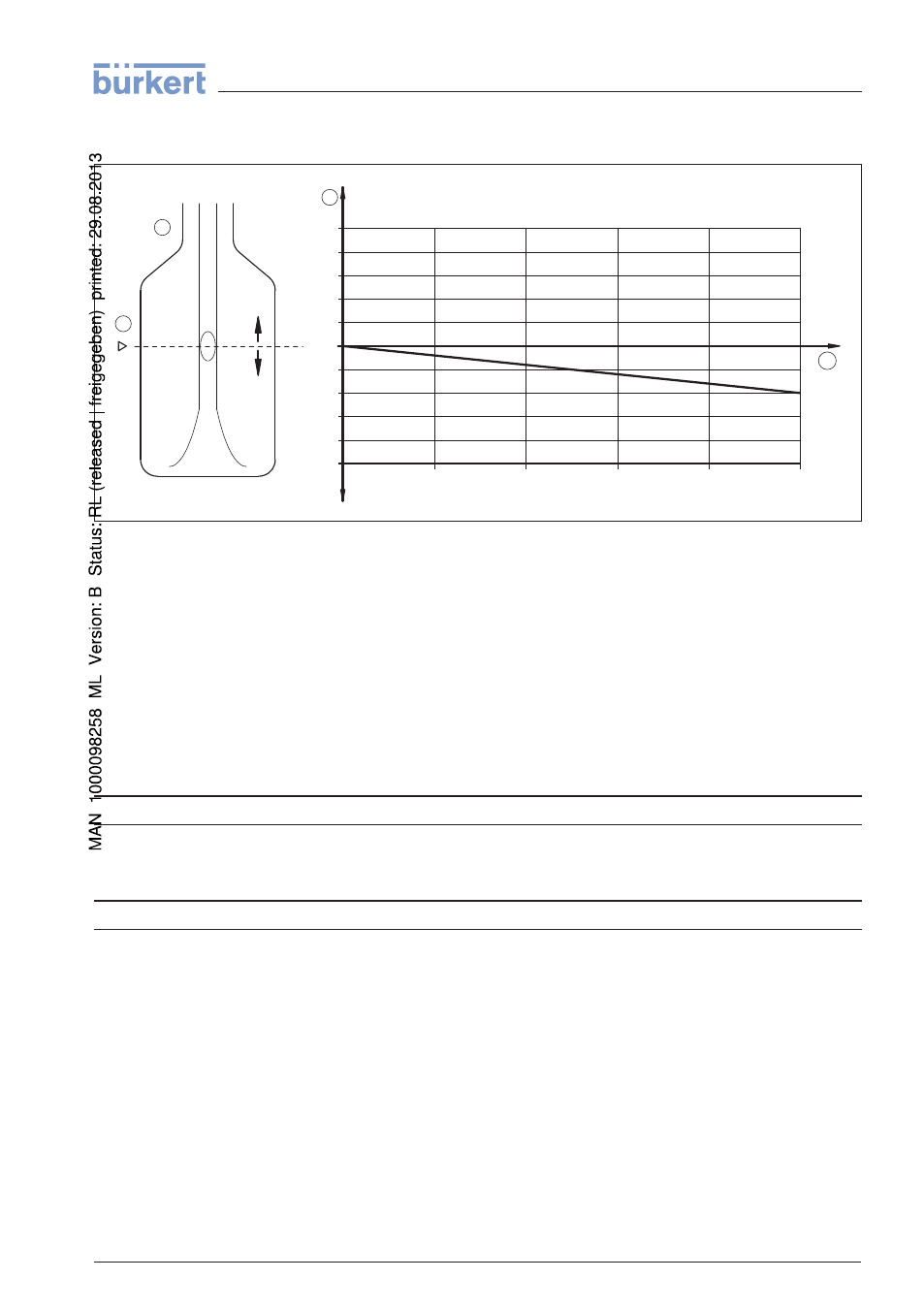

Influence of the process pressure to the switching point

1

2

3

4

12

(174,1)

38

(551,1)

25

(362,6)

51

(739,7)

64

(928,2)

10

(

25

/

64

")

8

(

5

/

16

")

6

(

15

/

64

")

4

(

5

/

32

")

2

(

5

/

64

")

-2

(

-5

/

64

")

-4

(

-5

/

32

")

-6

(

-15

/

64

")

-8

(

-5

/

16

")

-10

(

-25

/

64

")

0

Fig. 24: Influence of the process pressure to the switching point

1

Shifting of the switching point in mm (in)

2

Process pressure in bar (psig)

3

Switching point at reference conditions (notch)

4

Tuning fork

Repeatability

0.1 mm (0.004 in)

Hysteresis

approx. 2 mm (0.08 in) with vertical installation

Switching delay

approx. 500 ms (on/off)

Frequency

approx. 1200 Hz

Ambient conditions

Ambient temperature on the housing

-40 … +70 °C (-40 … +158 °F)

Storage and transport temperature

-40 … +80 °C (-40 … +176 °F)

Process conditions

Measured variable

Limit level of liquids

Process pressure

-1 … 64 bar/-100 … 6400 kPa (-14.5 … 928 psig)

depending on the process fitting, e.g. flange (see

following diagrams)

Process temperature (thread or flange tem-

perature)

-

LEVEL SWITCH

8112 of 316L/Hastelloy

C

22 (2.4602)

-50 … +150 °C (-58 … +302 °F)

Process temperature (thread or flange tem-

perature) with temperature adapter (option)

-

LEVEL SWITCH

8112 of 316L/Hastelloy

C

22 (2.4602)

-50 … +250 °C (-58 … +482 °F)

LEVEL SWITCH

8112 • with NAMUR output

29

9 Supplement

32052

-

EN

-

120418