Burkert Type 8112 User Manual

Page 28

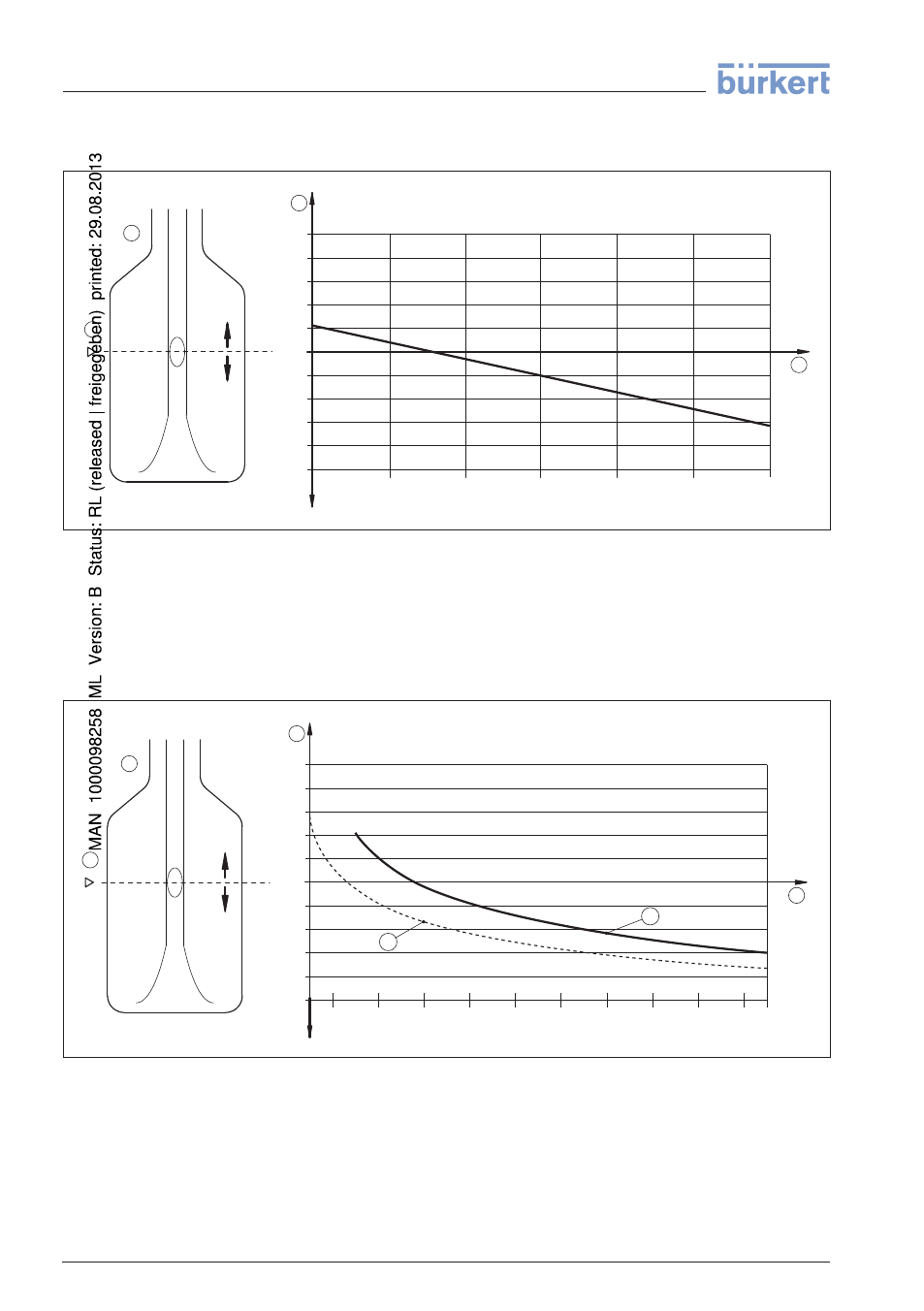

Influence of the process temperature on the switching point

1

3

4

2

10

(

25

/

64

")

8

(

5

/

16

")

6

(

15

/

64

")

4

(

5

/

32

")

2

(

5

/

64

")

-2

(

-5

/

64

")

-4

(

-5

/

32

")

-6

(

-15

/

64

")

-8

(

-5

/

16

")

-10

(

-25

/

64

")

0

0 °C

(32 °F)

100 °C

(212 °F)

150 °C

(302 °F)

200 °C

(392 °F)

250 °C

(482 °F)

50 °C

(122 °F)

Fig. 22: Influence of the process temperature on the switching point

1

Shifting of the switching point in mm (in)

2

Process temperature in °C (°F)

3

Switching point at reference conditions (notch)

4

Tuning fork

Influence of the product density on the switching point

1

2

4

3

5

6

1,2

(0,043)

1

(0,036)

0,8

(0,029)

0,6

(0,022)

1,4

(0,051)

1,6

(0,058)

1,8

(0,065)

2

(0,072)

2,2

(0,079)

2,4

(0,087)

10

(

25

/

64

")

8

(

5

/

16

")

6

(

15

/

64

")

4

(

5

/

32

")

2

(

5

/

64

")

-2

(

-5

/

64

")

-4

(

-5

/

32

")

-6

(

-15

/

64

")

-8

(

-5

/

16

")

-10

(

-25

/

64

")

0

Fig. 23: Influence of the product density on the switching point

1

Shifting of the switching point in mm (in)

2

Product density in g/cm³ (lb/in³)

3

Switch position 0.5 g/cm³ (0.018 lb/in³)

4

Switch position 0.7 g/cm³ (0.025 lb/in³)

5

Switching point at reference conditions (notch)

6

Tuning fork

28

LEVEL SWITCH

8112 • with NAMUR output

9 Supplement

32052

-EN

-120418