Measures to be taken before putting into service, Faults, English – Burkert Type 6525 User Manual

Page 18

16 - 6524/6525

I

NSTALLATION

, C

OMMISSIONING

AND

M

AINTENANCE

english

Measures to be taken before putting into service

Check all connections, voltages and the operational pressure!

Ensure that the max. operational conditions (see rating plate) will not be exceeded!

Unlock the manual actuator for electrical operation!

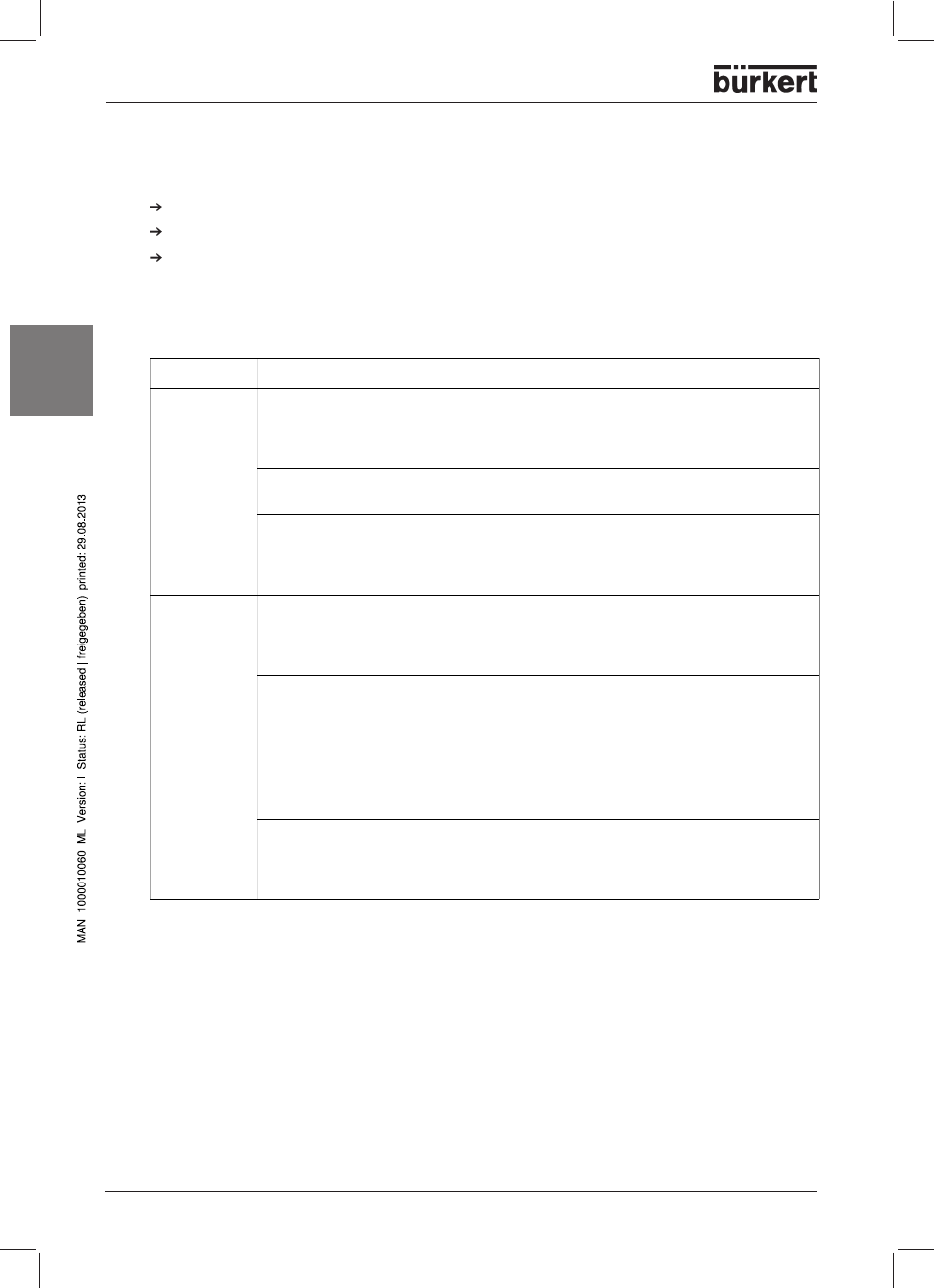

Faults

Fault

Possible cause

Correction

Valves does

not switch

Operational voltage too low or

not present

Check the electrical supply connections.

Ensure that the electrical power supply is the same as

that specified on the rating plate.

Manual override not in neutral

position

Set the manual override to the zero position.

Compressed air supply not

available or insufficient

Carry out the dimensioning of the compressed air

connection with volumes as large as possible (including

that of upstream pressure regulators, service units, cut-

off valves etc.).

Valves switch

with a delay, or

exhaust

through the

venting ports

Compressed air supply not

available or insufficient

Carry out the dimensioning of the compressed air

connection with volumes as large as possible (including

that of upstream pressure regulators, service units, cut-

off valves etc.).

Valves are not in the starting

position (without current)

during pressure build-up

Apply pressure to the valve block before you switch the

valves!

Insufficient venting of the

exhaust channels due to

silencers that are too small or

are soiled (backpressure)

Use silencers or expansion channels with sufficient

dimensions.

Clean soiled silencers.

Impurities or foreign matter in

the pilot valve or main valve

Blast through the exhaust channels with pulsed

compressed air, to blow out impurities.

Install a new pilot or main valve if these measures bring

no improvement.