Burkert Type 6027 User Manual

Page 5

16

7.4. Connecting the device socket

to the power supply

WARNING!

Risk of injury due to electrical shock!

• Before reaching into the system, switch off the electri-

cal power supply and secure to prevent reactivation!

• Observe applicable accident prevention and safety

regulations for electrical equipment!

If the protective conductor contact between the coil and

housing is missing, there is danger of electrical shock!

• Always connect protective conductor.

• Check electrical continuity between coil and housing.

Seal

max. 1 Nm

Approved device socket,

e.g. type 2508 or similar

Fig. 3:

Connecting the device socket to the power supply

english

17

8. MAINTENANCE AND REPAIRS

8.1. Safety instructions

DANGER!

Risk of injury from high pressure in the equipment!

• Before loosening the lines and valves, turn off the

pressure and vent the lines.

Risk of injury due to electrical shock!

• Before reaching into the system , switch off the power

supply and secure to prevent reactivation!

• Observe applicable accident prevention and safety

regulations for electrical equipment!

Risk of injury from improper repair work!

• Maintenance may only be carried out by authorized

technicians with the appropriate tools!

Risk of injury from unintentional activation of the

system and an uncontrolled restart!

• Secure system from unintentional activation.

• Following maintenance, ensure a controlled restart.

english

17

18

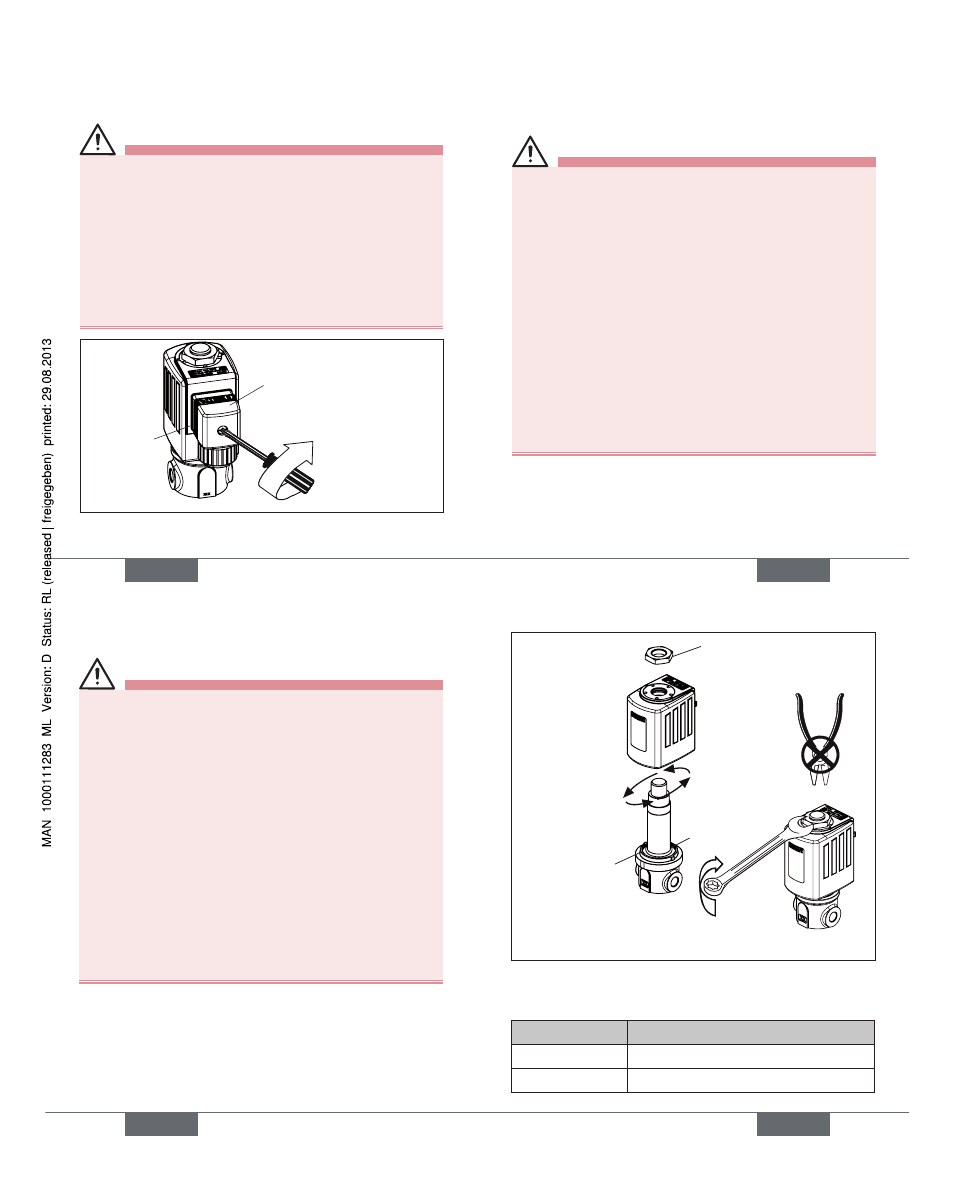

8.2. Installation of coil

WARNING!

Escaping medium!

When a sticking nut is loosened, medium may escape.

• Do not tighten sticking nut any further.

Electric shock!

If the protective conductor contact between the coil and

housing is missing, there is danger of electrical shock!

• During installation insert the plastic ring (optional) into

the housing journal. The plastic ring must not project

over the octagonal nipple.

• Check protective conductor contact after installing the

coil.

Overheating, risk of fire!

Connection of the coil without pre-assembled valve will

result in overheating and destroy the coil.

• Connect the coil with pre-assembled valve only.

english

19

Observe torque!

(See table below)

O-ring

Nut

Plastic ring

(optional)

Fig. 4:

Coil installation

The rotational position of the coil on the valve housing is arbitrary.

Wrench size

Coil installation torque

SW 14

5 Nm

SW 22

15 Nm

english

19

Type 6027