Burkert Type 6027 User Manual

Page 4

12

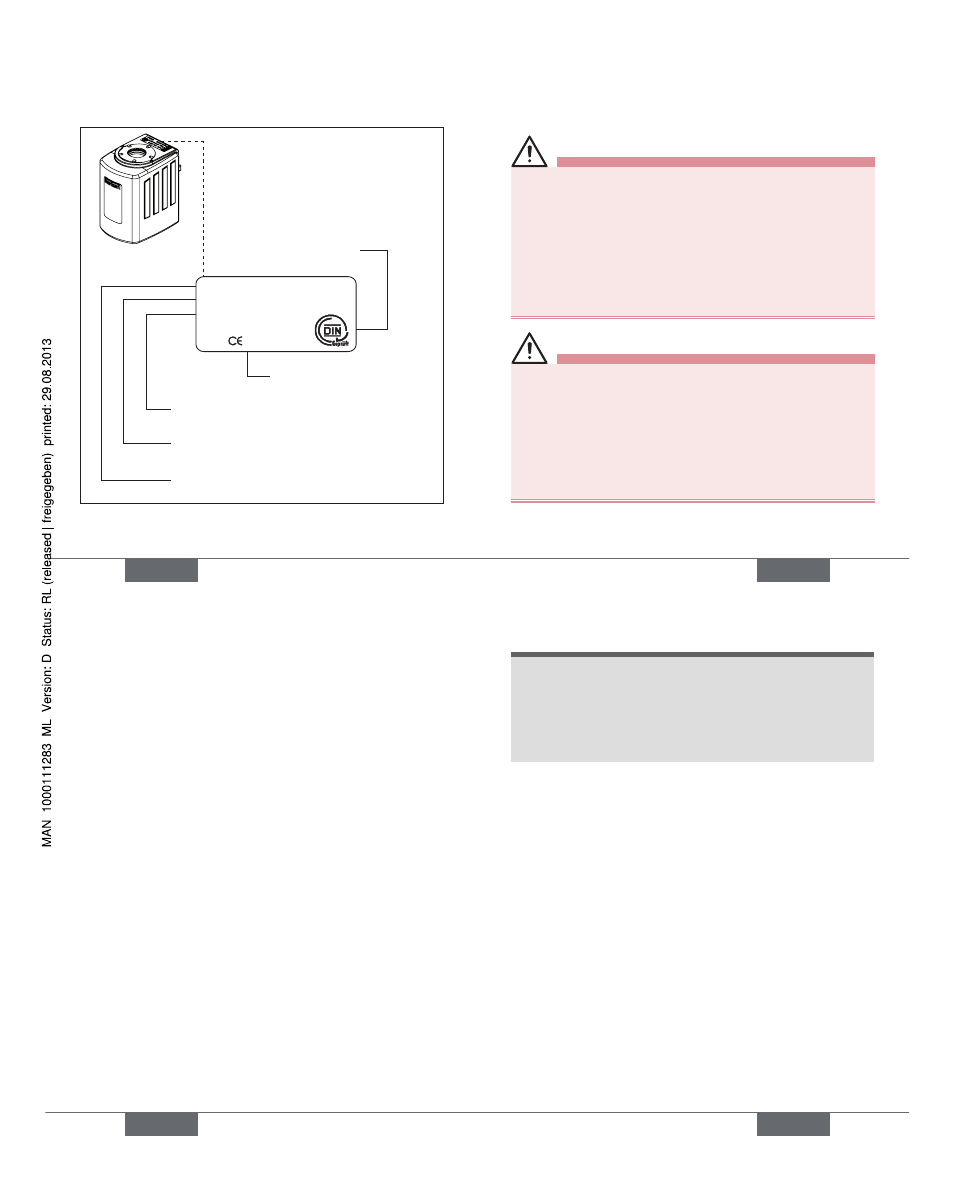

6.1.2. Type label approval

(depending on version)

Register number

Permitted ambient temperature

Max. permitted medium temperature

T med. Max. 160°C

T Umg. -15°C bis 60°C

Reg.Nr. XXXXX

0036

Inspection body

Certification mark

Fig. 2:

Location and description of the additional plate

english

13

7. INSTALLATION

7.1. Safety instructions

DANGER!

Risk of injury from high pressure in the system!

• Before loosening the lines and valves, turn off the

pressure and vent the lines.

Risk of injury due to electrical shock!

• Before reaching into the system , switch off the power

supply and secure to prevent reactivation!

• Observe applicable accident prevention and safety

regulations for electrical equipment!

WARNING!

Risk of injury from improper installation!

• Installation may only be carried out by authorized tech-

nicians with the appropriate tools!

Risk of injury from unintentional activation of the

system and an uncontrolled restart!

• Secure system from unintentional activation.

• Following assembly, ensure a controlled restart.

english

13

14

7.2. Before Installation

Installation position:

Installation can be in any position.

Preferably: Drive at the top.

→

Prior to installation check pipelines for dirt and clean if

necessary.

Dirt filter:

A dirt filter with a mesh width of ≤ 0.5 mm must be installed

in front of any safety shut-off devices along the flow path

before the burner nozzle. This is not necessary if a dirt filter

is integrated in the valve inlet. This does not apply for use as

a nozzle return flow valve.

7.3. Installation

→

Clean pipelines.

→

Only use new seals.

→

Hold the device with a suitable tool (open-end wrench)

on the housing and screw into the pipeline.

→

Observe flow direction:

When used in the feed flow: from 1 → 2 (from P → A)

or in the direction of the arrows.

When used in the return flow: from 2 → 1 (from A → P)

or in the opposite direction of the arrows.

english

15

NOTE!

Caution risk of breakage!

• Do not use the coil as a lifting arm.

If installed in the wrong direction it can lead to a mal-

function of the firing equipment.

• Observe direction of installation.

english

15

Type 6027