English, Pneumatic installation, Installation of the valve – Burkert Type 2700 User Manual

Page 10

8 - 2700

C

OMMISSIONING

english

The control valve is driven by compressed air via the Top

Control.

Control medium:

instrument air,

Class 3 to DIN ISO 8573-1

£

£

£

£

£

Remove the protective caps from the ports.

➔

➔

➔

➔

➔

Apply the supply pressure to port ”1”.

The supply pressure necessary for complete opening or closing of the valve

may lie between the minimum values of 3 and 6 bar, depending on the

actuator. The permissible maximum value for the control pressure is 7 bar. The

values for the pressure supply are given under p

Pilot

on the rating plate of each

control valve.

➔

➔

➔

➔

➔

Attach the exhaust line or silencer to port ”3”.

Pneumatic installation

May be installed in any position, but preferably with the drive unit above.

Observe the flow direction - general rule for control valves: flow input under

seat!

Clean the piping of contamination!

Before connecting the valve housing, take care that piping is aligned!

In the case of weld-on housings, be sure to remove the drive unit before

welding.

Procedure:

1. Remove the electrical and pneumatic supplies from the Top

Control.

2. Pull off the pneumatic hose between Top

Control and drive unit at control

connection of drive unit.

Installation of the valve

3. Control function A: Pressurize the lowr port of the actuator with

compressed air (6 bar), so that the control cone is lifted from the valve

seat and is not damaged.

Control function B: With control function B, no compressed air must be

applied for this purpose.

4. Remove the actuator in the open valve position by unscrewing the nipple

from the housing.

5. Before reinstalling the actuator (in the open valve position), grease the

nipple thread with stainless steel lubricant, e. g. Klüberpaste UH1 96-402

from Messrs. Klüber.

6. Replace the graphite seal.

7. After tightening the threaded nipple, align the control ports by turning the actuator.

ATTENTION!

The valve must be for this in the opened position

.

NOTE

When using in an aggressive environment, you are advised to connect pneumatic hoses to all free control

connections and place their other ends in a neutral atmosphere.

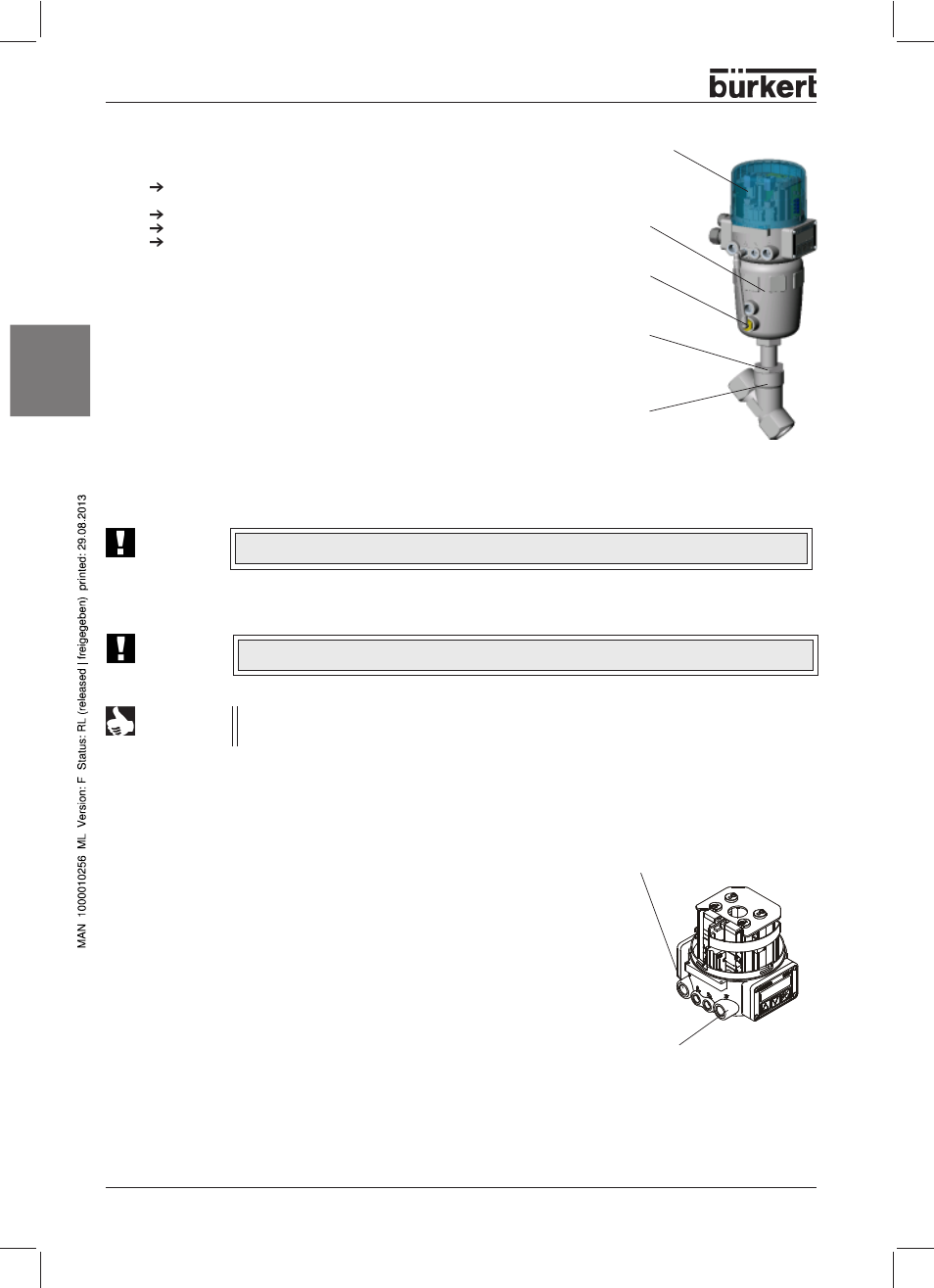

Fluidic connections of the

TopControl Continuous

Outlet air connector

(inscription: 3)

Supply pressure connector

(inscription: 1)

threaded

nipple

Top

Control

actuator

housing

lower

control port

ATTENTION!

For special applications such as for oxygen and analysis, use only the approved lubricants.