Burkert Type 0344 User Manual

Page 4

8

Danger!

Discharge of medium due to leaking device!

If the O-rings are forgotten or incorrectly inserted during installation

of the pilot valve, the device will be damaged and medium will be

discharged.

▶ Before screwing in the pilot valve, correctly insert O-rings into the

depressions.

5.5 electrical connection of the cable plug

Warning!

Risk of injury due to electrical shock!

▶ Before reaching into the system, switch off the power supply and

secure to prevent reactivation!

▶ Observe applicable accident prevention and safety regulations for

electrical equipment!

If the protective conductor contact between the coil and body is

missing, there is danger of electrical shock!

▶ Always connect protective conductor.

▶ Check electrical continuity between coil and body.

Procedure:

→

Tighten cable plug (for permitted types see data sheet), observing

max. torque 1 Nm.

→

Check that seal is fitted correctly.

→

Connect protective conductor and check electrical continuity between

coil and body.

english

9

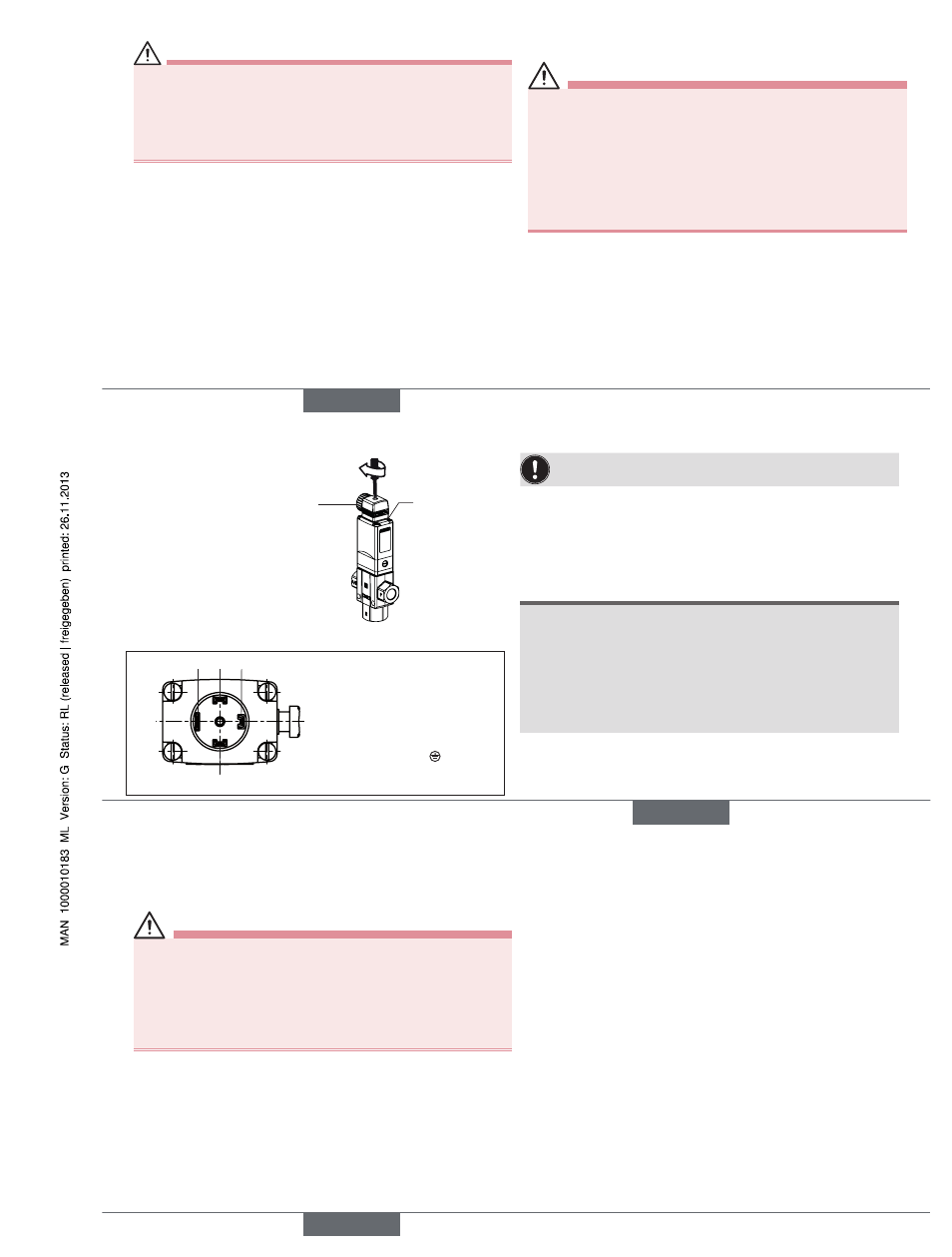

Authorized cable plug e.g.

Type 2508 or other suitable

cable plug in accordance with

DIN EN 175301-803 Form A

Seal

max. 1 Nm

5.5.1 electrical connection - pulse

DC connections:

Terminal 1 = closed +

Terminal 2 = open +

Terminal 3 = GND -

Terminal 4 = Protective conductor

Protective conductor

connection

2

4

3

1

The connection terminals in the cable plug are identified with

the numbers 1 to 3 according to the terminals on the valve.

Procedure:

→

Connect the pulse valves (variable code CF 02).

→

For direct current versions connect negative terminal to terminal 3.

note!

Important information:

• Avoid emitting pulses simultaneously to both coil windings.

• Do not switch any other consumers (relays, etc.) at the same time

as the terminals.

• The coil connection, to which voltage is not applied, must be galvani-

cally isolated (open).

• If two or more valves are switched in parallel, ensure that this

requirement is met by using 2-pole or multi-pole switches.

english

10

6

MainTenance, TrOuBleshOOTing

6.1 safety instructions

Warning!

Risk of injury from improper maintenance!

▶ Maintenance may be carried out by authorized technicians only and

with the appropriate tools!

Risk of injury from unintentional activation of the system and an

uncontrolled restart!

▶ Secure system from unintentional activation.

▶ Following maintenance, ensure a controlled restart.

6.2 Malfunctions

Type 0340: Shipment may have caused the position to occupy a

middle position.

Procedure:

→

Apply pressure to connection P and briefly seal connection A/B,

→

Using your finger, press piston through connection R into the end

position.

If malfunctions occur, check:

→

the device has been installed according to the instructions,

→

the electrical and fluid connections are correct,

→

the device is not damaged and all screws have been tightened,

→

the voltage and pressure have been switched on,

→

the pipelines are clean,

→

corresponding orifice is used in vacuum mode of the pump

capacity (Type 0343 / 0344).

→

Type 0343: operating and control pressure (control pressure must

be at least 2 bar above operating pressure).

Valve does not switch

Possible cause:

• Short-circuit or coil interrupted.

• Medium pressure outside the permitted pressure range.

• Manual emergency actuation locked.

Valve does not close

Possible cause:

• Internal space of the valve is dirty.

• Manual emergency actuation locked.

english

Type 0340, 0343, 0344