5installation – Burkert Type 0344 User Manual

Page 3

5

Operating principle 3/2-way valve Type 0343:

Standard Version

C

(NC)

A

P R

T

Z

Continuity A → R normally open,

connect vacuum generator to R,

external air to P, auxiliary control air to Z

D

(NO)

B

P R

T

Z

Continuity P → B normally open,

connect vacuum generator to R,

external air to P, auxiliary control air to Z

1)

The externally controlled valve, Type 0343, requires auxiliary control air which

is at least 2 bar above operating pressure

Protection class:

IP65 in accordance with DIN EN 60529 /

IEC 60529 with cable plug, e. g. Bürkert

Type 2508

4.2 application conditions

Ambient temperature:

0 °C ... +55 °C

Medium temperature:

0 °C ... +90 °C

Viscosity (Type 0340):

21 mm

2

/s

Media

Type 0340:

neutral media, compressed air, water,

hydraulic oil

Type 0343 / 0344:

neutral gas, compressed air, vacuum

Operating duration:

Unless otherwise indicated on the type label,

the solenoid system is suitable for continuous

operation

Important information for functional reliability during continuous

operation! If standstill for a long period at least 1-2 operation

per day are recommended.

Service life:

High switching frequency and high pressures

reduce the service life

4.3 conformity

In accordance with the EC Declaration of conformity, the solenoid valve

Type 0340, 0343 and 0344 is compliant with the EC Directives.

4.4 standards

The applied standards, which verify conformity with the EC Directives,

can be found on the EC Type Examination Certificate and / or the EC

Declaration of Conformity.

english

6

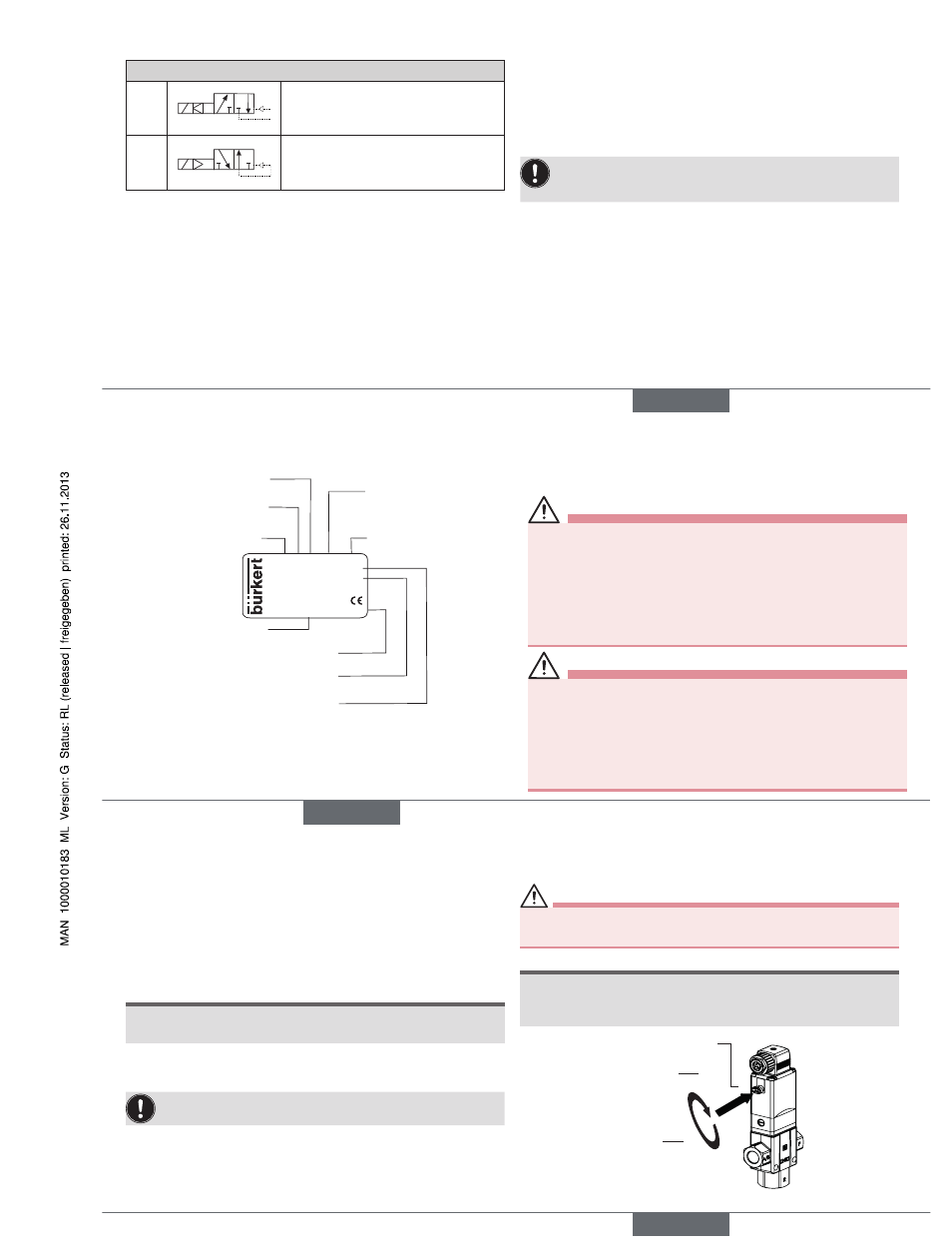

4.5 Type label

Type

Operating

principle

Orifice

Seal material

Body material

Id.- Number

Manufacture-Code

Voltage, Frequency, Power

consumption

Connection thread, Operating

pressure

0340 C 12,0 NBR MS

Made in Germany

00041346

W17MG

230V 50 Hz 8W

G1/2 P

N 0,5

- 1

6 bar

5

insTallaTiOn

5.1 safety instructions

Danger!

Risk of injury from high pressure in the equipment!

▶ Before loosening the lines and valves, turn off the pressure and

vent the lines.

Risk of injury due to electrical shock!

▶ Before reaching into the system, switch off the power supply and

secure to prevent reactivation!

▶ Observe applicable accident prevention and safety regulations for

electrical equipment!

Warning!

Risk of injury from improper installation!

▶ Installation may be carried out by authorized technicians only and

with the appropriate tools!

Risk of injury from unintentional activation of the system and an

uncontrolled restart!

▶ Secure system from unintentional activation.

▶ Following installation, ensure a controlled restart.

english

7

5.2 Before installation

Installation position: any, actuator preferably upwards.

Procedure:

→

Check pipelines for dirt and clean.

→

Install a dirt filter before the valve inlet (≤ 500 µm).

5.3 installation

note!

Caution risk of breakage!

• Do not use the coil as a lifting arm.

→

Hold the device with a open-end wrench on the body and screw

into the pipeline.

Valve body must not be installed under tension.

→

Observe pin assignment according to switching function and

identification.

5.4 Manual emergency actuation

Caution!

Discharge of medium due to loss of the O-rings!

▶ If the O-rings are lost, the valve will leak. Medium may be discharged.

note!

Caution!

• When the manual emergency actuation is locked, the valve can no

longer be actuated electrically.

Manual emergency

actuation

Press

Turn

1

2

english

Type 0340, 0343, 0344