D. chain installation (continued) – FlexLink Конвейерная цепь Монтаж User Manual

Page 2

470

D. Chain installation

D. Chain installation (continued)

Using a beam section for chain installation

The beam section X_CC 160/XKCC 200 is used to per-

mit chain installation anywhere along the conveyor.

Tools required

Procedure

Length adjustment of the conveyor chain

End drive, intermediate drive and catenary drive units

1 Adjustment of the conveyor chain is carried out at the

drive end of the conveyor.

2 Remove catenary protection plates to allow easy

access for the pin insertion tool.

3 The conveyor chain should be tensioned within the

conveyor system by pulling down the conveyor chain

at the chain catenary in the underside of the drive unit.

Clamp across the conveyor chain to trap the chain on

to the beam profile. The clamp should be placed over

the edges of the drive unit to reduce the risk of dam-

age to the aluminium profile.

4 Remove all slack links from the conveyor chain using

the pin insertion tool.

5 Rejoin the conveyor chain.

6 Remove the chain clamp and reinstall the catenary

protection plates. The conveyor is now ready for oper-

ation.

Horizontal bend drive units

In a wheel bend drive, the outer aluminium profile can be

removed by slackening the set screws in the beam con-

necting strips. The slide rail must be fitted to allow the

removal of this section. A slide rail fastened with rivets

must not be longer than the outer bend section.

1 After removal of the outer aluminium profile, the con-

veyor chain can be pulled out of the wheel bend disc.

Lift the chain upwards.

2 Remove chain links using the pin insertion tool.

3 Rejoin the chain ends.

4 The tensioned chain can now be pulled back into

position on the bend guide disc, and the outer profile

put into place.

Guided drive units

Drive unit types X_EB HLG/HRG, X_EB HLGP/HRGP.

1 Adjustment of the conveyor chain is carried out at the

idler end unit.

2 Undo the screws on one side plate and remove it.

3 Undo the screw holding the shaft. Remove the idler

wheel together with the shaft.

4 Remove the required number of links.

5 Reinstall the idler wheel and shaft together with the

chain. Tighten the screw that holds the shaft.

6 Reinstall the side plates, make sure that the slide rails

are properly installed. Tighten the screws.

3 Join 5 meter lengths of

chain when necessary.

4 Remove links if neces-

sary, so that the chain

will exhibit some slack

at the drive unit. Length

adjustment, see

page 470.

Join the chain ends.

See page 469.

Allen key

Pin insertion tool

X..MJ

Clamp

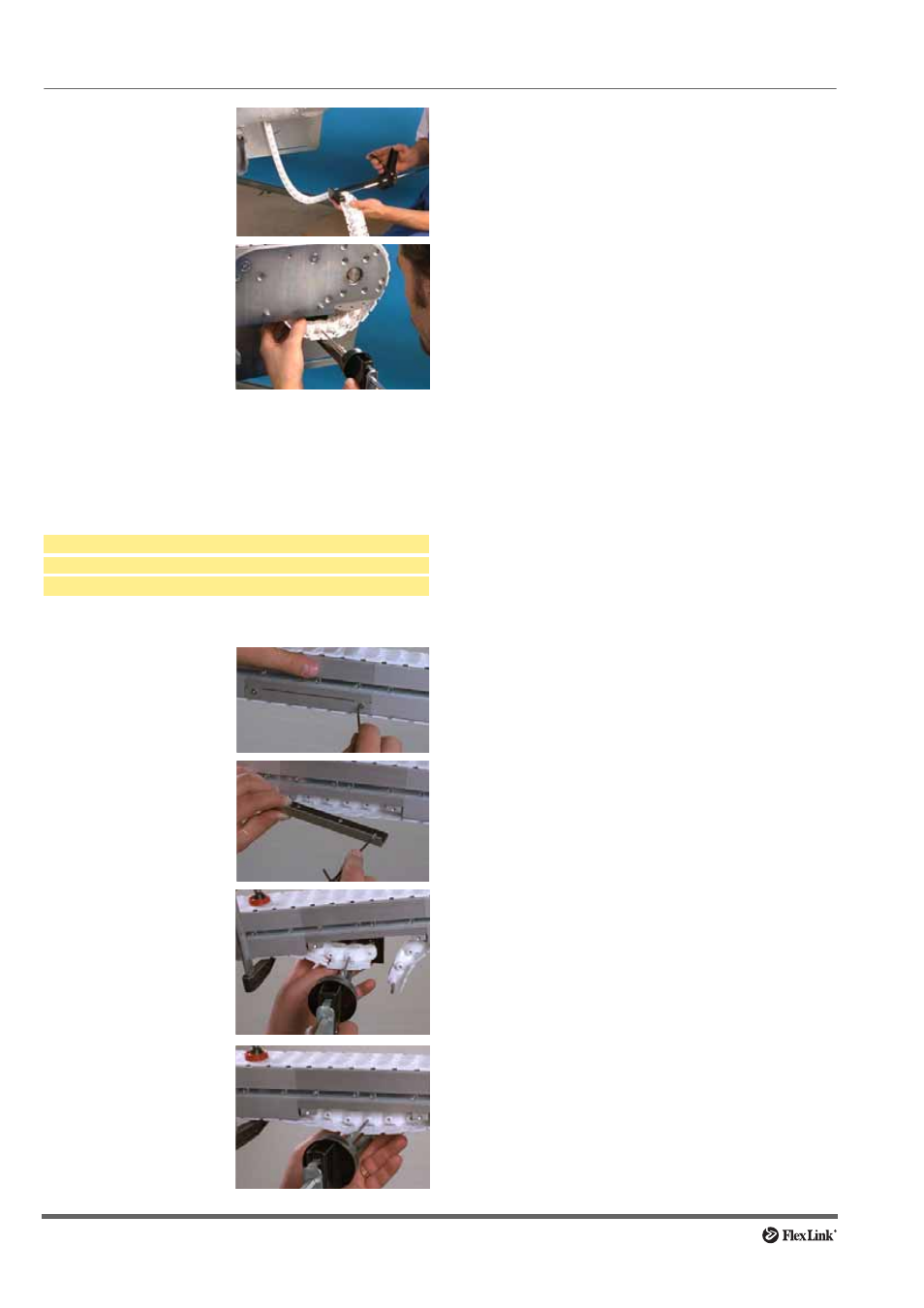

1 Loosen the screws on

the beam section

flanges

2 Remove the flange so

that the chain becomes

accessible.

3 Clamp the chain to the

beam profile. Use the

chain tool to remove a

steel pin from the chain,

so that two links are

separated.

4 Remove excess links

and use the chain tool to

join the chain ends.