Part 2 - transducer installation, Unpacking – Dynasonics DDFXD Doppler Ultrasonic Flow Meter User Manual

Page 13

06-DPP-UM-00147 02/12

13

PART 2 - TRANSDUCER INSTALLATION

UNPACKING

After unpacking, it is recommended to save the shipping carton and packing materials in case the instru-

ment is stored or re-shipped. Inspect the equipment and carton for damage. If there is evidence of ship-

ping damage, notify the carrier immediately.

MOUNTING LOCATIONS

The transducers that are utilized by the DFX contain piezoelectric crystals for transmitting and receiv-

ing ultrasonic sound energy through the pipe wall in the case of the series DT9 transducer and from the

probe tip of the series DP7. Placement of the ultrasonic transducer is the most critical step in achieving

an accurate and reliable flow reading. All flow meters of this type rely on a full-pipe of fluid that is flowing

symmetrically (evenly) in the pipe. Flow in partially filled pipes and immediately downstream of elbows,

valves and pumps is unstable and will lead to unstable readings and non-linearity.

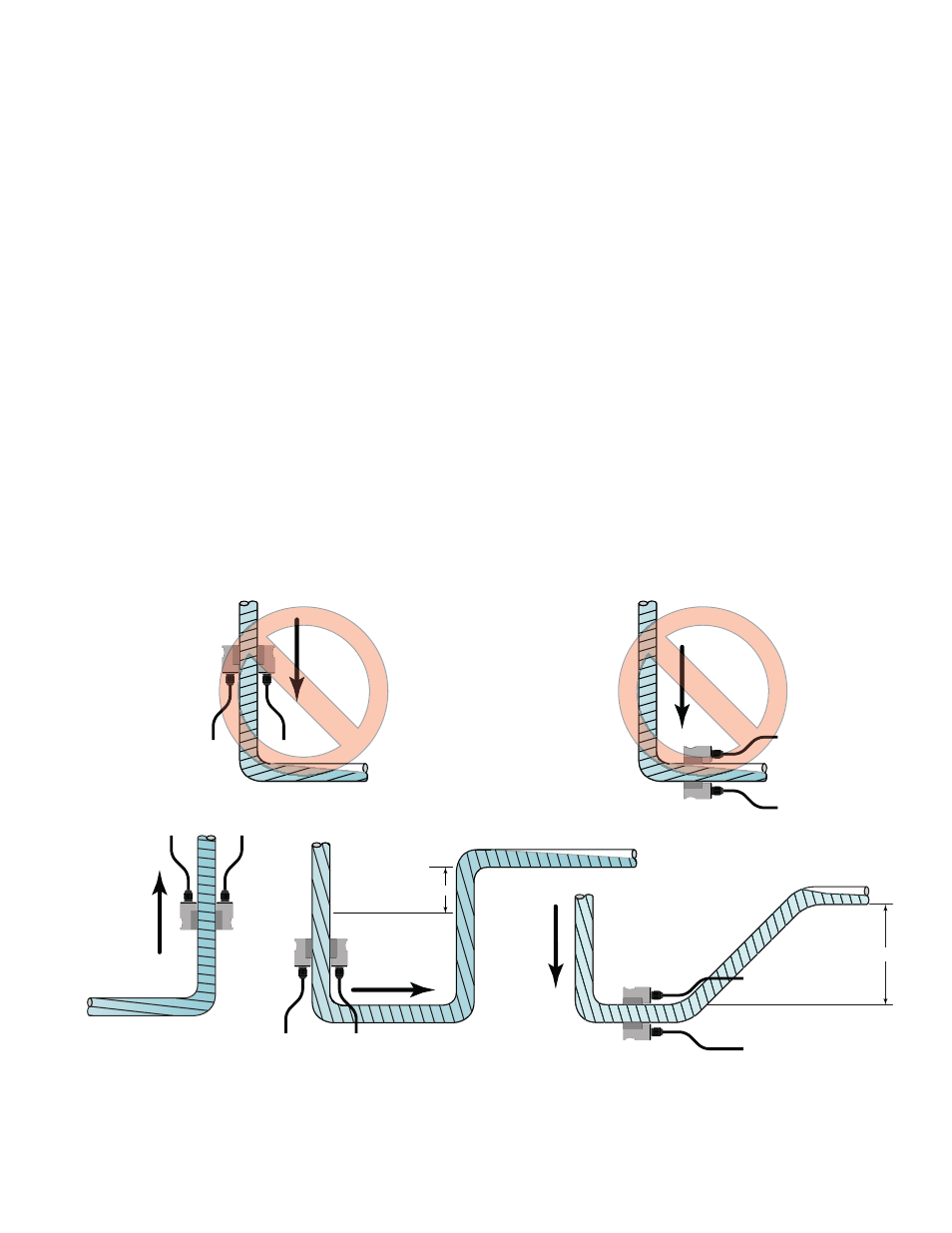

Figure 2.1 illustrates five possible pipe configurations and recommends installation only in locations

where it can be guaranteed that the pipe will be filled at all times when flow measurements are required.

The two locations illustrated in the top two drawings may allow the meter to operate, but it is unlikely

that stable and accurate flow readings will be realized over a very large range of flow. Since products like

the DFX have software algorithms that assume a full-pipe of liquid, partially-filled pipes can lead to very

large flow measurement errors and should be avoided.

h

h

FIGURE 2.1 - PIPE CONFIGURATIONS AND INSTALLATION RECOMMENDATIONS