Sharpening the drill bit, Problem – Drill Doctor XP User Manual

Page 7

www.drilldoctor.com

11

10

www.drilldoctor.com

Sharpening the Drill Bit

Before sharpening you should know:

•

Keep the Cam in contact with the Cam Guide as you

sharpen—push the Chuck straight into the port.

•

Only light pressure is required.

•

You will hear a grinding noise (

z

z

z

z

z

z

z

z

z

) as you

complete each half-turn and each side of the bit face is

ground.

•

The Chuck will rock as you turn it and the Cam rides

on the Cam Guide.

•

It will be easier to sharpen bits standing up

The number of turns needed to sharpen the bit

depends on the size.

•

Turn the Chuck an even number of half-turns with

light, inward pressure:

3/32 inch bits

—use 2 to 4 half-turns,

1/8 inch bits

—use 4 to 6 half-turns,

3/8 inch bits

—use 16 to 20 half-turns.

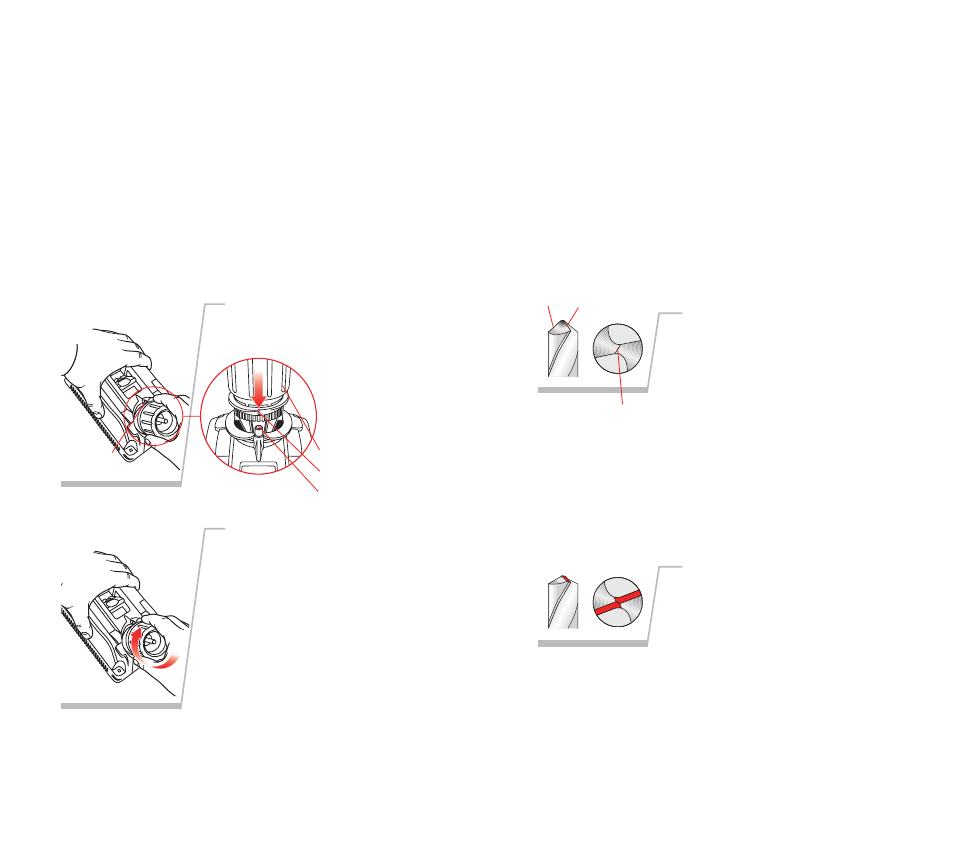

Identifying Correctly Sharpened Drill Bits

(and what to do with those that aren’t!)

Correctly Sharpened Bits

Incorrectly Sharpened Bits

1.

Align Guides

Turn the Drill Doctor on.

Align either of the Sharpening

Guides with the

Cam Guide on the

machine. Insert

Chuck in Align-

ment Port.

2.

Insert Chuck and turn

until sharp

Insert the Chuck in the

Sharpening Port. Making

sure you keep the cam

against the cam guide, rotate

the Chuck one half-turn in a

clockwise direction—from

Sharpening Guide to Sharp-

ening Guide — an even num-

ber of times. Your motion

should be smooth and even.

To sharpen both sides of the

bit evenly, always use an

even number of half-turns.

Cam

Cam Guide

Heel

Chisel Edge

Cutting Edge

Sharpening Guide

Sharpening

Guide

The entire surface from the Cut-

ting Edge to the Heel will have a

finely ground surface without

ridges or indentations. The Heel

will always be lower than the

Cutting Edge (positive relief.)

The Chisel Edge will be clean and

straight.

Cause

Chuck Jaws did not grip drill bit

properly in the aligning process

(Page 8).

Solution

Realign the bit by carefully fol-

lowing steps 1 through 5 on

Pages 8 to 9.

Problem

The Chisel Edge is

ground flat.