Identifying basic drill bits, Anatomy of a drill bit, The drill doctor – Drill Doctor XP User Manual

Page 5: Sharpening process

www.drilldoctor.com

7

6

www.drilldoctor.com

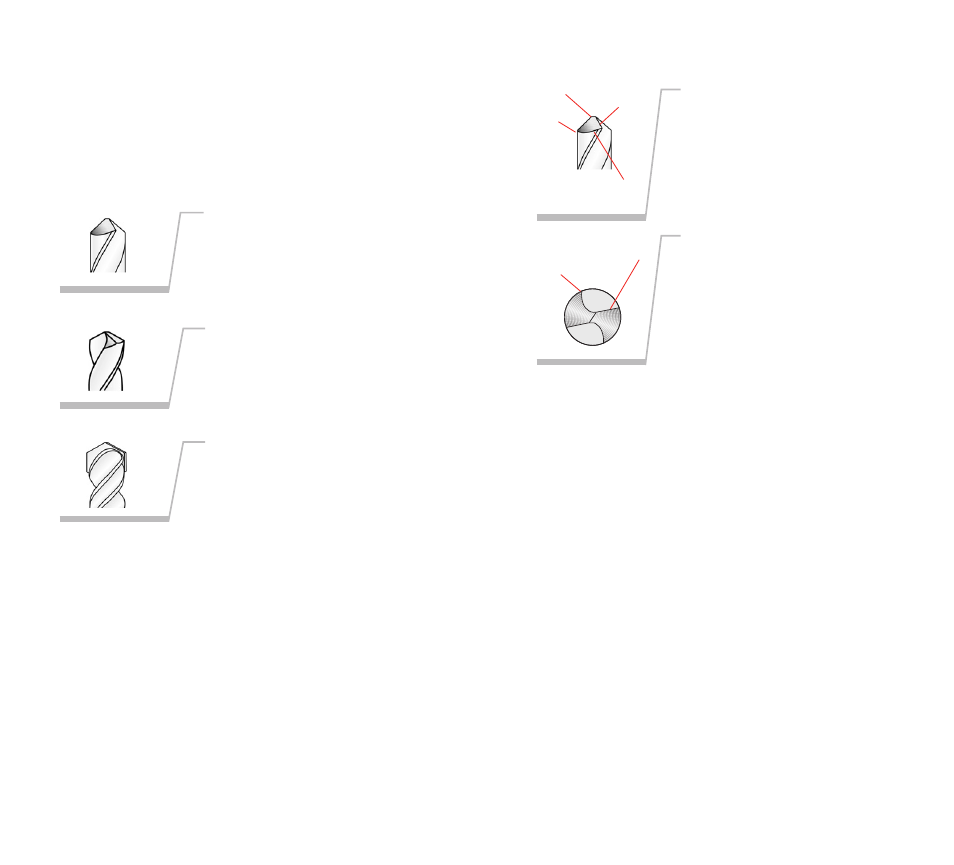

Identifying Basic Drill Bits

The Drill Doctor

®

is most efficient when used to resharpen

a drill bit’s original point angle. With its standard

Diamond Sharpening Wheel it will sharpen high-speed

steel, cobalt, TiN-coated, carbide and masonry drill bits.

It has been designed and engineered to sharpen three of

the most common drill bit types:

Standard Point

This general-purpose point is

used for drilling softer materials

like cold rolled steel, aluminum,

and wood.

Split Point

Split-point bits are self-centering

and are generally used for tem-

pered steels, hard alloys or hard

cast materials.

Masonry Bits

Masonry bits have a carbide

insert at the point and are used

for drilling materials like cement,

brick, and ceramic.

Anatomy of a Drill Bit

Chisel

Edge

It is important to understand that

each bit has all of these charac-

teristics.

Cutting

Edge

Heel

Relief

Angle

When viewing a well-sharpened

bit from the end, the entire sur-

face from the Cutting Edge to the

Heel will have a finely ground

surface without ridges or indenta-

tions. The Heel will always be

lower than the Cutting Edge.

Cutting Edge

The Drill Doctor

®

Sharpening Process

The sharpening process includes 3 easy procedures:

1.

Align the bit in the Chuck.

2.

Sharpen the bit.

3.

Split the point (if you choose).

Be sure to complete all three of the procedures to sharpen

and split a bit and always sharpen the bit prior to splitting it.

Heel