Drill Doctor 250_300 User Manual

Step 1, Step 2, Step 3

B

Drill Doctor

®

250 Handyman

Warranty

Your Drill Doctor® 250 Handyman is warranted to be free of

defects due to workmanship and design for 1 year from

purchase date.

If your Drill Doctor® fails to operate or if any operating

problem occurs, contact Drill Doctor® Technical Service toll

free at:

1-800-597-6170

.

See warranty card for instructions on warranty service.

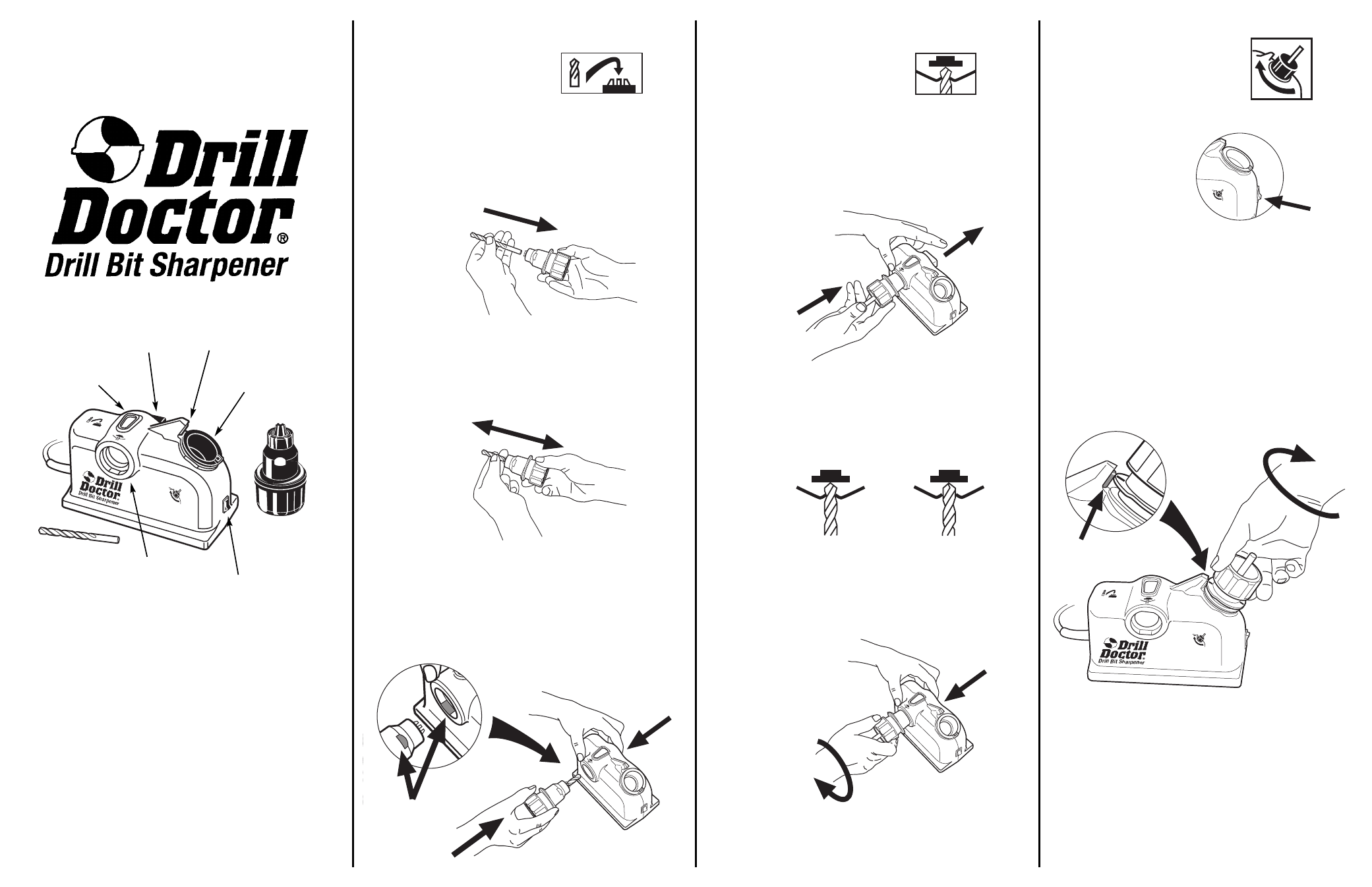

step 1

SIZING

THE CHUCK

ALIGNING

THE DRILL BIT

SHARPENING

THE DRILL BIT

A

Insert the drill bit into the chuck. Turn the chuck knob

clockwise until it is tight.

B

Now, loosen the chuck knob slightly, turning counterclockwise,

just until the drill bit begins to slide through the chuck jaws.

C

Press the pusher button in and insert the chucked drill bit

into the alignment tube. Take care to match the flats on

the chuck with the flats on the top and bottom of the tube.

step 2

A

C

Release the pusher button and rotate the drill bit until the

clamp arms grip the bit at its narrowest width.

1. Tighten the chuck clockwise until the bit is securely

held in the chuck.

2. Press the pusher button in once more, and then

remove the chuck and drill bit together from the alignment

tube. Your bit is ready to sharpen.

Gently push the drill bit forward until it meets the drill stop,

which is visible through the alignment viewer.

step 3

A

B

Turn the Drill Doctor® on.

1

2

Owners Instruction Sheet

PP20500KF REV 2 (06/00)

1

2

ON / OFF

Drill Stop

CORRECT

INCORRECT

FLATS

Clamp

Arms

Insert the chucked drill bit into the sharpening tube,

matching either white mark on the chuck with the cam

post at the top of the tube. With a direct, easy

pressure, turn the chuck clockwise, white mark to white

mark and repeat. Remember you are grinding steel.

A small bit requires a light pressure and may only take

a couple of turns to sharpen. A large bit will need

greater pressure and will take additional turns or more

to sharpen.

Make sure the chuck follows the steel cam post.

Avoid putting downward pressure on the chuck.

Keep the pressure even, and directed into the tube.

The correct sharpening action will naturally rock the

chuck back and forth. This motion should not be

prevented. A 1/4” bit will need about 6 complete

rotations of the chuck, or 12-20 half rotations, to

achieve a perfectly sharp point. More sharpening may

be required for very dull or broken bits.

CAM POST

Pusher

Button

Alignment

Viewer

Alignment

Tube

Sharpening

Tube

3/32” to 1/2”

Chuck

Cam Post

On/Off Switch