English – CEMB USA ER80 (B) User Manual

Page 20

20

Use and maintenance manual Rev. 10-2011

ENGLISH

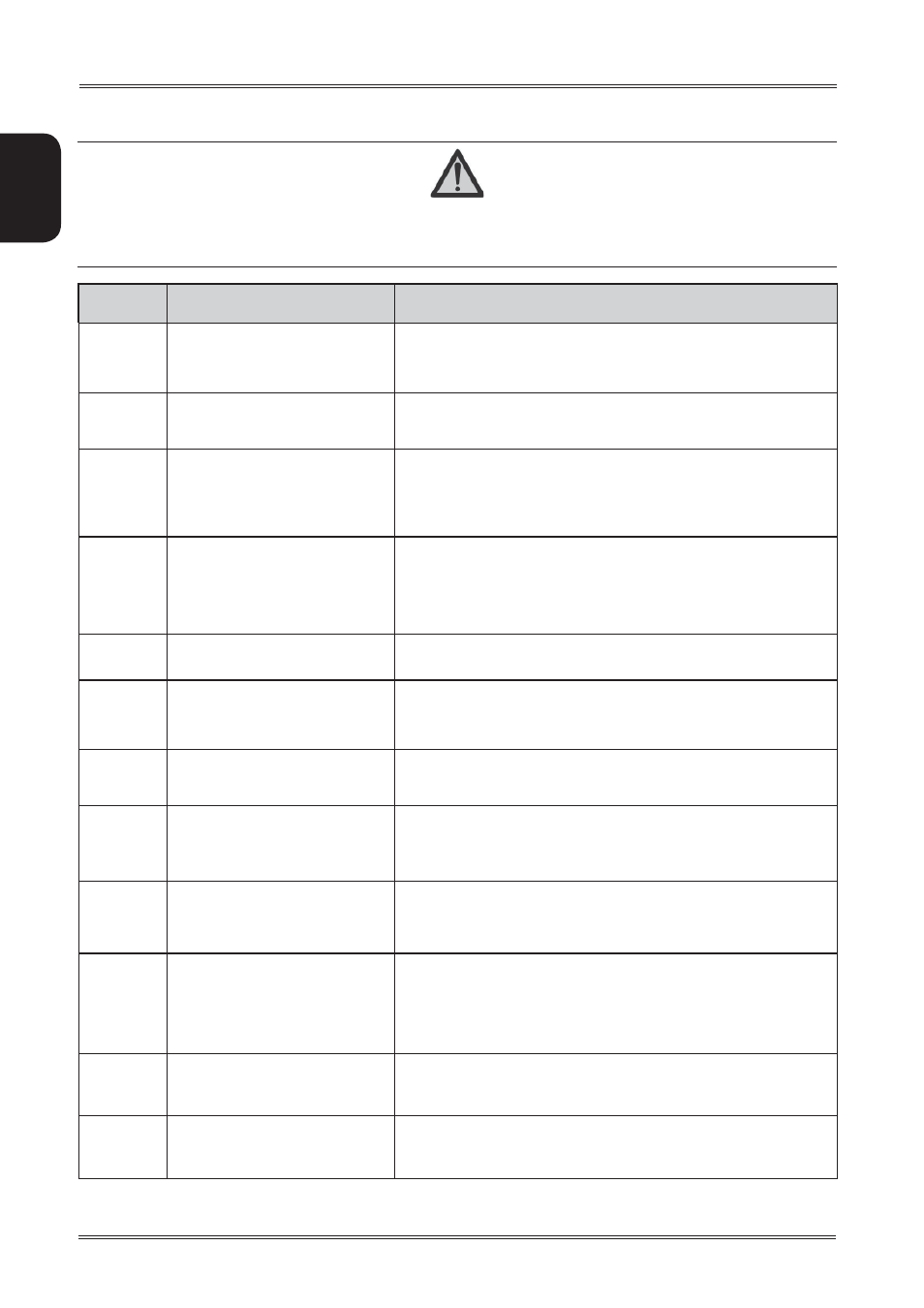

Diagnostics

WARNING

T

HE

INFORMATION

IN

THE

POSSIBLE REMEDY

COLUMN

REQUIRES

WORK

TO

BE

PERFORMED

BY

SPECIALIST

TECHNICIANS

OR

OTHER

AUTHOR

-

ISED

PEOPLE

WHO

MUST

ALWAYS

WORK

USING

THE

P

ERSONAL

P

ROTECTIVE

E

QUIPMENT

INDICATED

IN

THE

INSTALLATION

MANUAL

. I

N

SOME

CASES

,

THIS

WORK

CAN

BE

PERFORMED

BY

A

NORMAL

OPERATOR

.

ERROR

CAUSE

POSSIBLE REMEDY

Black

The wheel balancer does not

switch on.

Check the machine is properly connected to the mains power

1.

supply.

Check the fuses on the power board and replace if necessary.

2.

Replace the CPU board.

3.

Err. 1

No rotation signal.

Use the self-diagnostics function to check the encoder.

1.

Replace the encoder.

2.

Replace the CPU board.

3.

Err. 2

Speed too low during detection.

During the unbalance measure-

ment revolutions, the wheel speed

has fallen to below 42 rpm.

Make sure that a vehicle wheel is mounted on the wheel balancer.

1.

Use the self-diagnostics function to check the encoder.

2.

Disconnect the piezo connectors from the board and do a spin

3.

(if no error is detected, replace the piezo sensors).

Replace the CPU board.

4.

Err. 3

Unbalance too high.

Check the wheel dimensions setting.

1.

Check the detection unit connections.

2.

Run the machine calibration function.

3.

Mount a wheel with more or less know

4.

n unbalance (less than

100 grams) and check the response of the machine.

Replace the CPU board.

5.

Err. 4

Rotation in opposite direction.

Use the self-diagnostics function to check the encoder.

1.

Check the encoder bearing/spring.

2.

Err. 5

Guard open

The [START] pushbutton was

pressed without fi rst closing the

guard.

1. Reset the error.

2. Close the guard.

3. Verify the function of the protection switch.

4. Press the [START] button.

Err. 6

Spindle open (SE version)

The guard has been closed

without fi rst closing the spindle

1. Reset the error

2. Close the spindle

3. Close the guard.

Err. 7

Err. 8

Err. 9

NOVRAM parameter read error

Switch off the machine and wait for at least ~ 1 min;

1.

re-start the machine and check it works properly.

Repeat machine calibration.

2.

Replace the CPU board.

3.

Err. 11

Too high speed error.

The average spinning speed is

more than

240 rpm.

1. Check functioning of the phase encoder and, in particular, the

reset signal.

2. Replace the computer board.

Err.14

Err.15

Err.16

Err.17

Err.18

Err. 19

Unbalance measurement error.

Use the self-diagnostics function to check the encoder.

1.

Check the detection unit connections.

2.

Check the machine earthing connection.

3.

Mount a wheel with more or less known unbalance (less than

4.

100 grams) and check the response of the machine.

Replace the CPU board.

5.

Err. 20

Wheel still. The wheel must

remain still for more than one

second after START.

Use the self-diagnostics function to check the encoder.

1.

Check the connections on the power board.

2.

Replace the CPU board.

3.

Err. 21

Motor on for more than 15

seconds.

1. Use the self-diagnostics function to check the encoder.

2. Check the connections on the power board.

3. Replace the CPU board.