2 unbalance optimisation, 3 self-diagnostics, 4 calibration – CEMB USA ER80 (B) User Manual

Page 16: English, Tyre position rim position

16

Use and maintenance manual Rev. 10-2011

ENGLISH

6.2 UNBALANCE

OPTIMISATION

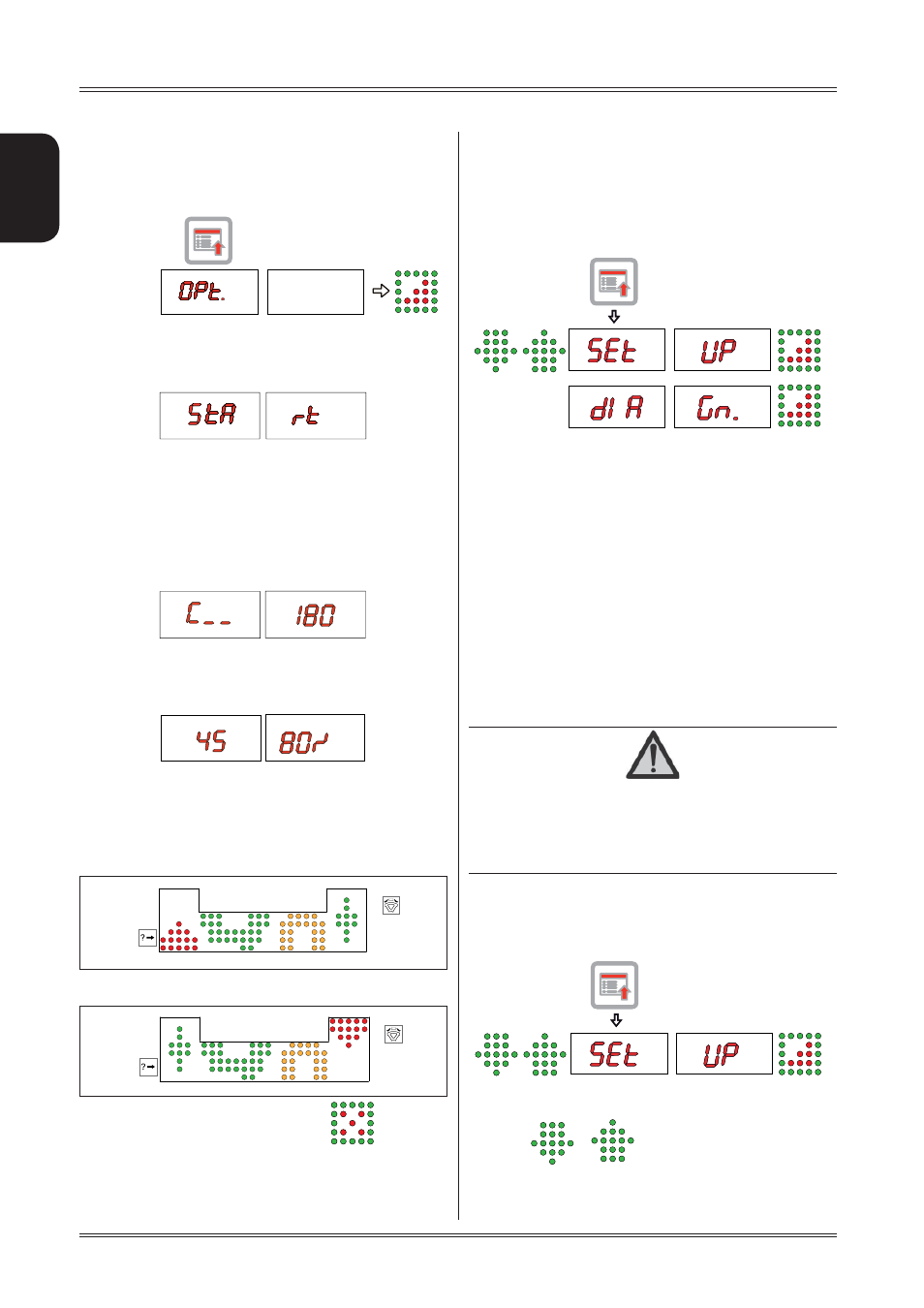

This operation is performed to reduce the static unba-

lance of the wheel.

It is suitable for static unbalance values in excess of 30

grams.

I

a. f no unbalance was measured before, START appears

on the display. Press this button to proceed. Close the

guard to perform a spin.

Mak

b.

e a reference mark on the flange and the rim (using

a piece of chalk, for example).

With the aid of a tyre remover, turn the tyre on the rim

by 180°.

Refi t the wheel in such a way that the reference marks

on the rim and the fl ange coincide.

Close the guard to perform a spin.

RH displ

c.

ay: percentage reduction value

LH display: actual static unbalance value which can be

reduced by rotation

Ma

d.

rk the two positions of the rim and tyre, and turn the

tyre on the rim until the positions coincide to achieve

the optimisation shown on the display

To finish optimisation, press the button

when indi-

cated on the displays. When optimisation is complete, close

the guard to perform a new spin or press anywhere on the

touch panel to return to the measurement screen.

6.3

SELF-DIAGNOSTICS

The machine can perform self-diagnostics to check the

LED’s on the control panel and make sure the encoder

reads correctly.

To perform this operation, view the SETUP menu.

In the self-diagnostics sequence, all the LED’s on the pa-

nel light up for a few seconds in order to check operation.

When the LED’s go out, the machine automatically moves

on to the encoder reading phase. When the wheel is turned

manually (forwards and backwards), the display shows its

exact position. The value lies between 0 (zero) and 255.

6.4

CALIBRATION

To calibrate the machine, proceed as follows:

Fit an average size wheel with a metal rim on the shaft.

▪

Example: 6” x 15” (± 1”).

Set the wheel measurements as described in paragraph

▪

USE OF THE WHEEL BALANCER.

CAUTION

S

ETTING

INCORRECT

DIMENSIONS

WOULD

MEAN

THAT

THE

MACHINE

IS

NOT

CORRECTLY

CALIBRATED

, T

HEREFORE

,

ALL

SUBSEQUENT

MEASUREMENTS

WILL

BE

INCORRECT

UNTIL

CALIBRATION

IS

PER

-

FORMED

ONCE

AGAIN

WITH

THE

CORRECT

DIMENSIONS

.

Display the SETUP menu:

TYRE POSITION

RIM POSITION

Setup

P

1. ress

/

to view the CALIBRATION

function.