5 running the feed – PA Industries Magnum Servo Roll Feed SRF-M12/18/24/32/36/48 - Installation and Operating Instructions User Manual

Page 9

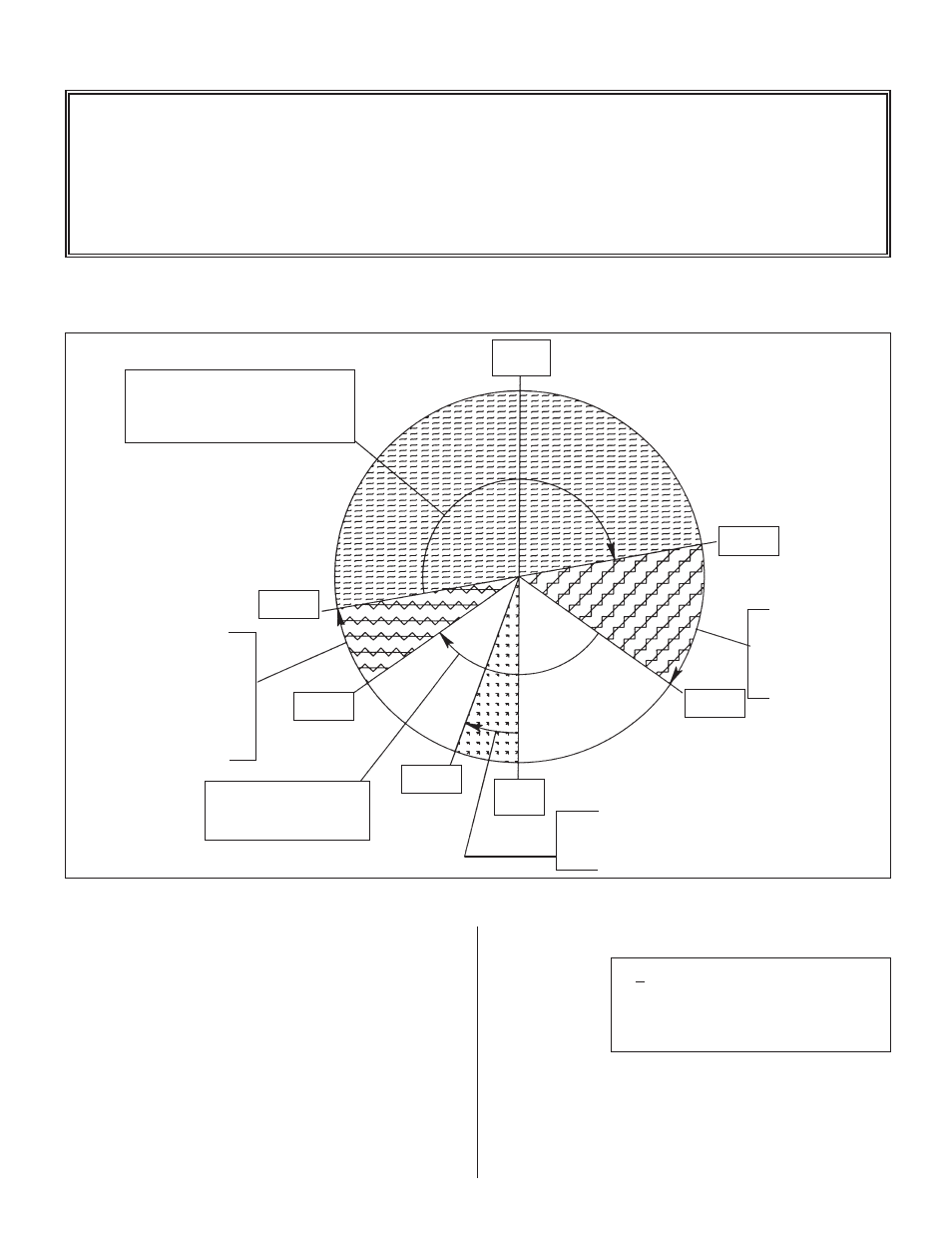

TYPICAL 180 DEGREE FEED ANGLE (FROM 260 DEGREES TO 80 DEGREES)

WITH MECHANICAL PILOT RELEASE:

9

FEED ADVANCE CAM

180° FEED ANGLE

FEEDER STARTS FEEDING AT 260°

AND MUST BE IN POSITION AT 80°

WORKING ANGLE

(PUNCHES IN STRIP)

FEED CAM

“ON”

FEED CAM

“OFF”

FEED MUST BE

“IN POSITION”

SAFETY ANGLE

;

PRESS RAM MUST

STOP IN THIS ZONE

IN EVENT OF A

FEED ERROR

ROLL OPENING

ZONE FOR PNEUMATIC

PILOT RELEASE

DRAWING 17141-02

CONTINUE CAM SIGNAL

CONTINUE CAM

“ON” AT 180°

CONTINUE CAM

“OFF” AT 200°

Figure 5. FEED ANGLE

260°

80°

125°

TDC

0°

180°

BDC

235°

200°

ROLL CLOSING

ZONE;

FEED ROLLS

MUST FULLY CLOSE

IN THIS ZONE

TO PREVENT ROLL

SLIPPAGE AT START

OF FEEDING

5.5 RUNNING THE FEED

NOTE ABOUT CAMS:

The Feed Advance Cam (open tool): The feed

system uses this press cam for timing the feeder

to the press crankshaft. Although no shafting or

belts actually connect the press to the feeder, the

feed must be “told” when it is safe to move the

strip and when the feed move must be completed.

• This “connection” is an electrical one, and not a

mechanical one. This gives the operator/set-up

personnel total flexibility in deciding when the feed

progression should take place.

• Each die set can have a unique “feed angle”. This “feed

angle” is dependent upon many variables; pilot and

punch length, press stroke, strip forming in the die, etc.

All the adjustments to the feed system and press

have now been made. The press is at Top Dead

Center (

TDC

) and ready for automatic cycling.

Proceed by inching the press thru another stroke,

verifying that things are happening at the correct

time (pilot release, feed advance). If the system is

operating properly you can make a few more "hits",

check your parts and then put the press into

continuous mode.

The Magnum Servo Roll Feed will now follow

the press until it is stopped by the Operator,

counter, emergency stop, or feed error.

The display will show:

The speed performance chart (Figure 6) is to be

used as a guide only. Actual feeder/press speeds

may vary depending on factors such as material

thickness, width, rigidity, surface finish, and line

payoff/straightener conditions.

LENGTH

00001.253

COUNT

001000

SPEED

0060/SEC

BATCH RUNNING