Troubleshooting guide – PA Industries Magnum Servo Roll Feed SRF-M12/18/24/32/36/48 - Installation and Operating Instructions User Manual

Page 11

11

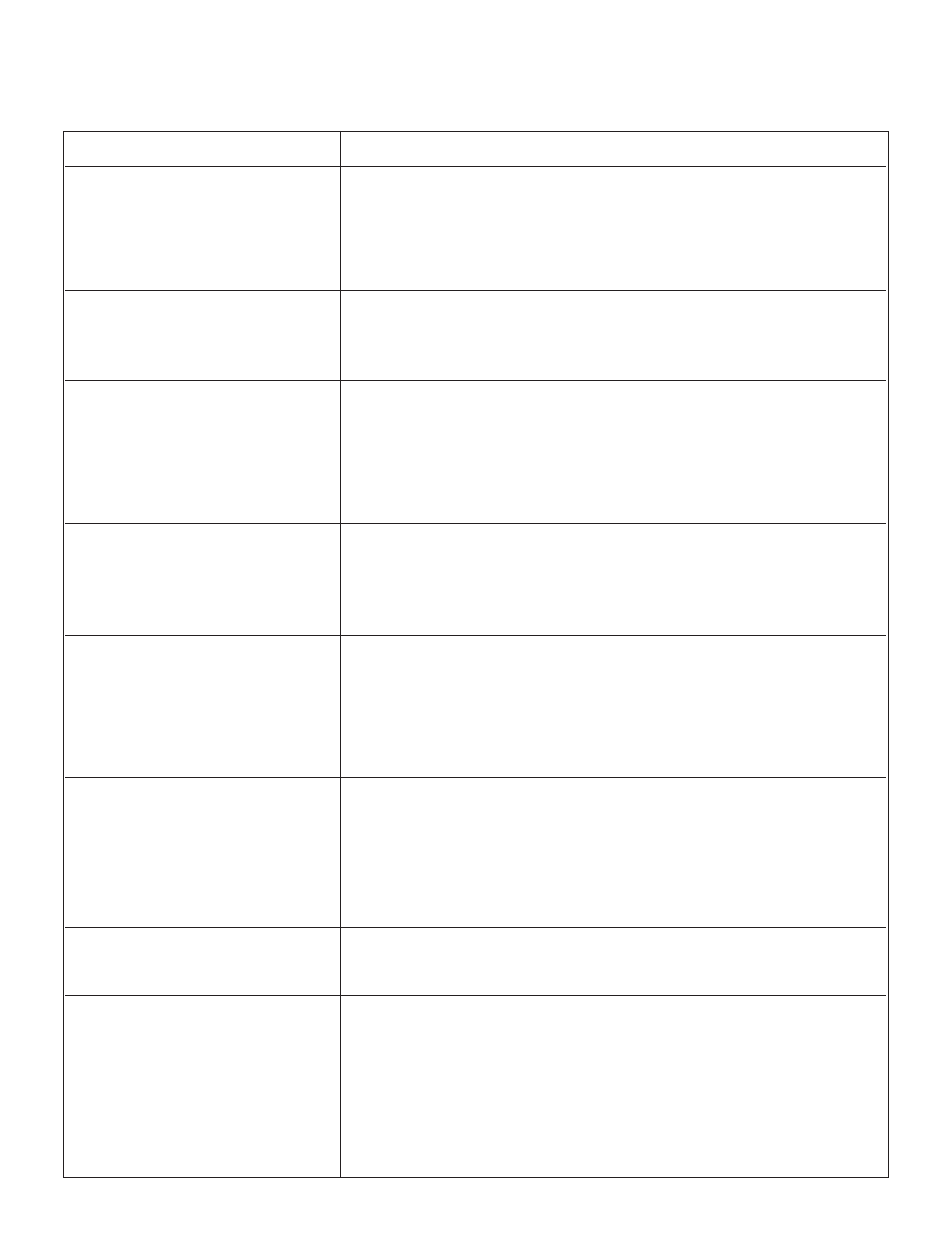

SYMPTOM

CAUSE or REMEDY

No power indication when

• Check main power supply for proper voltage.

‘POWER ON’ button is pressed

• Check supply fuses and circuit breakers.

• Verify that the main disconnect switch is on.

• Verify that the E-Stop is not engaged (E-Stop Loop closed.)

• Check bulb in ‘POWER ON’ push button.

No display on power up

• Check cabling connection between display and servo drive.

• Check 5 Volt logic supply LED on motion control card on right side

of Servo Drive/Amplifier under orange connectors.

• Check fuses in drive under right side cover.

Feed will not jog

• Check that the Feed is in manual mode. Move selector switch to ‘AUTO’;

press the ‘POWER ON’ push button to reset control.

• Check if the Feed is in ‘SET-UP’ mode. Waiting for press.

• Check if ‘IN POSITION’ indicator is off. Check parameters. Check drive

for Error Codes.

• Check ‘FAULT’ in display. i.e. ‘SERVO AMP FAULT’. Check drive for Error

Code. See Section 6.1

‘POWER ON’ indicator is lit,

• Check that the ‘IN POSITION’ indicator is lit. If not, check parameters.

Feed will not operate.

• Check that the Error message is in the Display. If so, check error

description in Section 6.1

• Move selector switch to Auto, press ‘POWER ON’ button (E-Stop will show

in display), release ‘POWER ON’ button, try to jog feeder.

Feed will not accept new feed

• Check that the Selector switch is in Set-Up mode (running Set-Up program).

length or other parameters

• Check that the Selector switch is in Auto mode and ‘CYCLE START’ has

been pressed (running Auto Program). Press ‘POWER ON’ push button

to reset.

• Check that the Run/Program toggle switch is in ‘RUN’ position; this will only

allow length, speed, and count to be changed. Set the Program Position;

then the Program position will allow any parameter to be changed.

Inaccurate feeding

• Adjust rolls for correct material thickness. Check thickness gauge.

• Adjust air pressure.

• Confirm if rolls are slipping on strip. Remove oil from feed rolls, reduce

acceleration, check tool for binding/slugs, etc.

• Adjust Upstream Equipment if Upstream equipment not providing

adequate/consistent free loop.

• Check roll release for proper settings.

Feed runs backwards

• Check for negative feed length, i.e. minus sign in length (–5.125).

• Verify that direction parameter has been reset. Check CW or CCW

direction parameter.

Servo Amp Fault

This is a generic display prompt indicating a fault on the Servo Amplifier.

• Look at the diagnostic display on the Servo Amplifier. The cause of the

fault can be determined by reading the Error Code.

• Refer to Sections 6.1 and 6.2. This fault condition can be caused by any

one of the errors in the lists.

• Check for Error Code first, then reset the Servo Amplifier by turning the

power off, waiting 10 seconds, then powering back on.

• Verify that the fault will not reset. Call the factory for assistance.

6. TROUBLESHOOTING GUIDE

The chart that follows contains the most frequently encountered issues.