PA Industries Magnum Servo Roll Feed SRF-M12/18/24/32/36/48 - Installation and Operating Instructions User Manual

Page 8

8

3. Open the feed rolls with the ‘

OPEN/CLOSE

’

rolls switch on the jog pendant. Insert the material

and close the feed rolls.

4. Adjust the roll clamping pressure via the

pressure regulator located on the material inlet side

of the feed in the top cover. Adjust the pressure

until the liquid filled gage reads approximately

40 psi.

5. Using the ‘

JOG FORWARD

’ button on the jog

pendant, advance the material up to the entrance of

the die (but not too far where the punches would

pierce the material).

6. Check the vertical alignment of the strip. If

necessary, adjust the pass line of the feeder so that

the material is at the proper height.

7. Assuming that the press shut height and the

tool are set up properly, jog the press one or two

strokes without the feed working.

8. Now jog the press down slowly observing when

the longest pilot would engage the pilot hole in the

material if it were there. (Refer to Figure 4.) Note

the press positional readout and put this setting into

your Programmable Limit Switch (

PLS

) for the

‘

PILOT RELEASE TURN ON

’ setting. The ‘

PILOT

RELEASE TURN OFF

’ setting should be 180. (See

Figure 5.)

9. Continue to jog the press slowly until the

longest pilot just comes above the material. Note

the press positional readout and put this setting into

your PLS for the ‘

FEED ADVANCE TURN ON

’

setting. Set the ‘

FEED ADVANCE TURN OFF

’

point approximately 30 degrees less than the pilot

release turn on point. (See Figure 5.)

10. Set the continue cam to turn on at 180 degrees

and to turn off at 200 degrees. This setting should

never need changing. (See Figure 5.)

STRIP

PILOT PIN

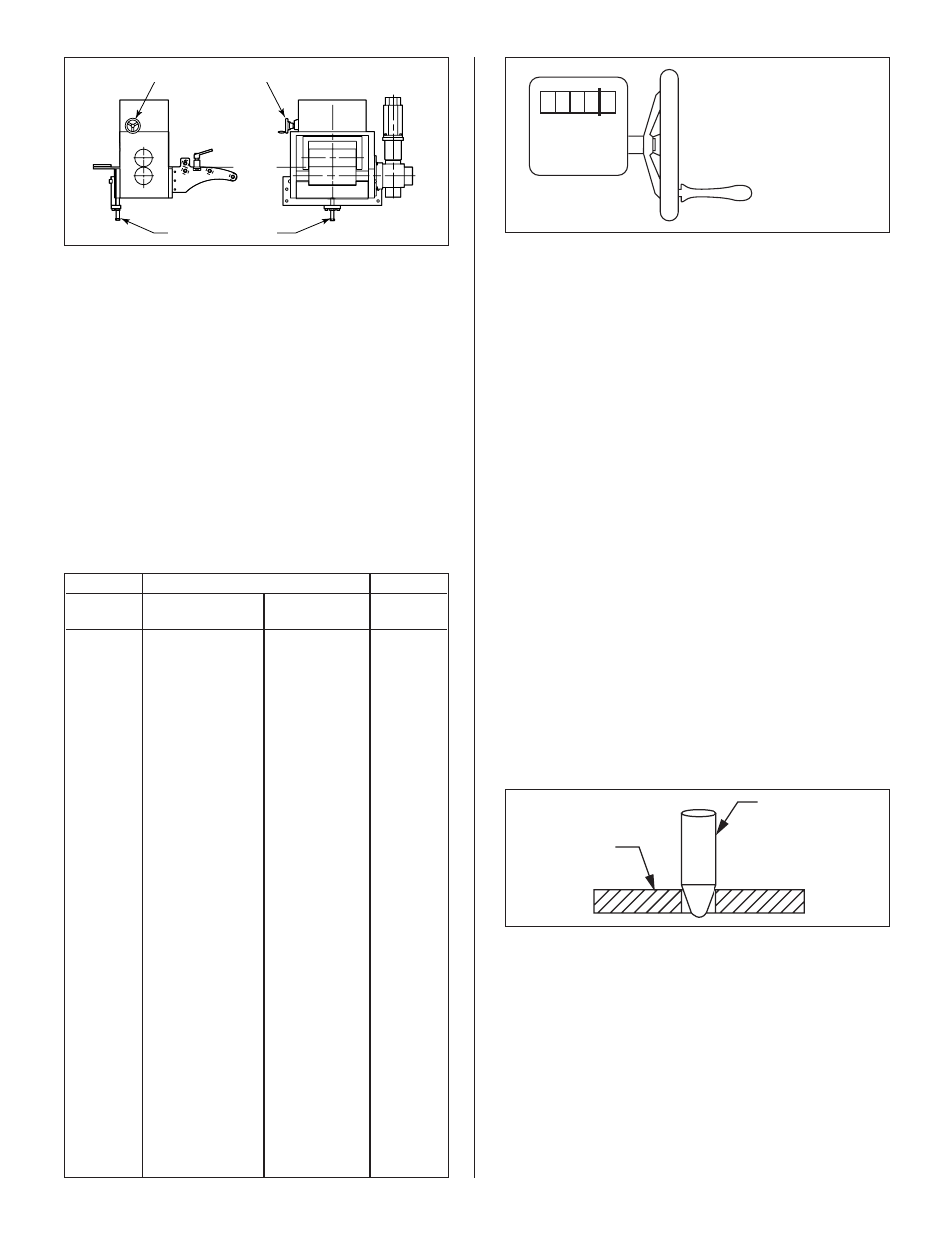

Figure 4. PILOT PIN

0 0 3 4 0

This reading = 3.40 mm

(.134”) thickness

PASS LINE ADJUST

MATERIAL THICKNESS ADJUSTMENT HANDLE/WHEEL

Figure 3.

Use the following steps to load the feeder:

(Refer to Figure 3.)

1. Record the present settings of the thickness,

feed advance cam, continue cam, and pilot release

cam into a job set-up record sheet for future

reference to the job (see Programmable Limit Switch

Job Set-Up Sheet).

2. Refer to the Thickness Setting Chart shown

below (also located on the feed body near the thickness

adjustment handle). Adjust the material thickness

dial for the proper material thickness. Refer to the

example in the following drawing for proper setting.

Steel Coil Thickness

Mfg. Std.

Inch Equiv.

Metric Equiv.

Dial

Gage No.

for Steel Sheet

mm

Setting

–

.2500

6.35

0063[5]

3

.2391

6.07

0060[7]

4

.2242

5.69

0056[9]

5

.2092

5.31

0053[1]

6

.1943

4.94

0049[4]

–

.1875

4.76

0047[6]

7

.1793

4.55

0045[5]

8

.1644

4.18

0041[8]

9

.1495

3.80

0038[0]

10

.1345

3.42

0034[2]

11

.1196

3.04

0030[4]

12

.1046

2.66

0026[6]

13

.0897

2.28

0022[8]

14

.0747

1.90

0019[0]

15

.0673

1.71

0017[1]

16

.0598

1.52

0015[2]

17

.0538

1.37

0013[7]

18

.0478

1.21

0012[1]

19

.0418

1.06

0010[6]

20

.0359

0.91

0009[1]

21

.0329

0.84

0008[4]

22

.0299

0.76

0007[6]

23

.0269

0.68

0006[8]

24

.0239

0.61

0006[1]

25

.0209

0.53

0005[3]

26

.0179

0.45

0014[5]

27

.0164

0.42

0004[2]

28

.0149

0.38

0003[8]

29

.0135

0.34

0003[4]

30

.0120

0.30

0003[0]

THICKNESS SETTING CHART