2 ddm drive error messages, 3 run time error codes, 4 power-up error codes – PA Industries Magnum Servo Roll Feed SRF-M12/18/24/32/36/48 - Installation and Operating Instructions User Manual

Page 13: Maintenance

13

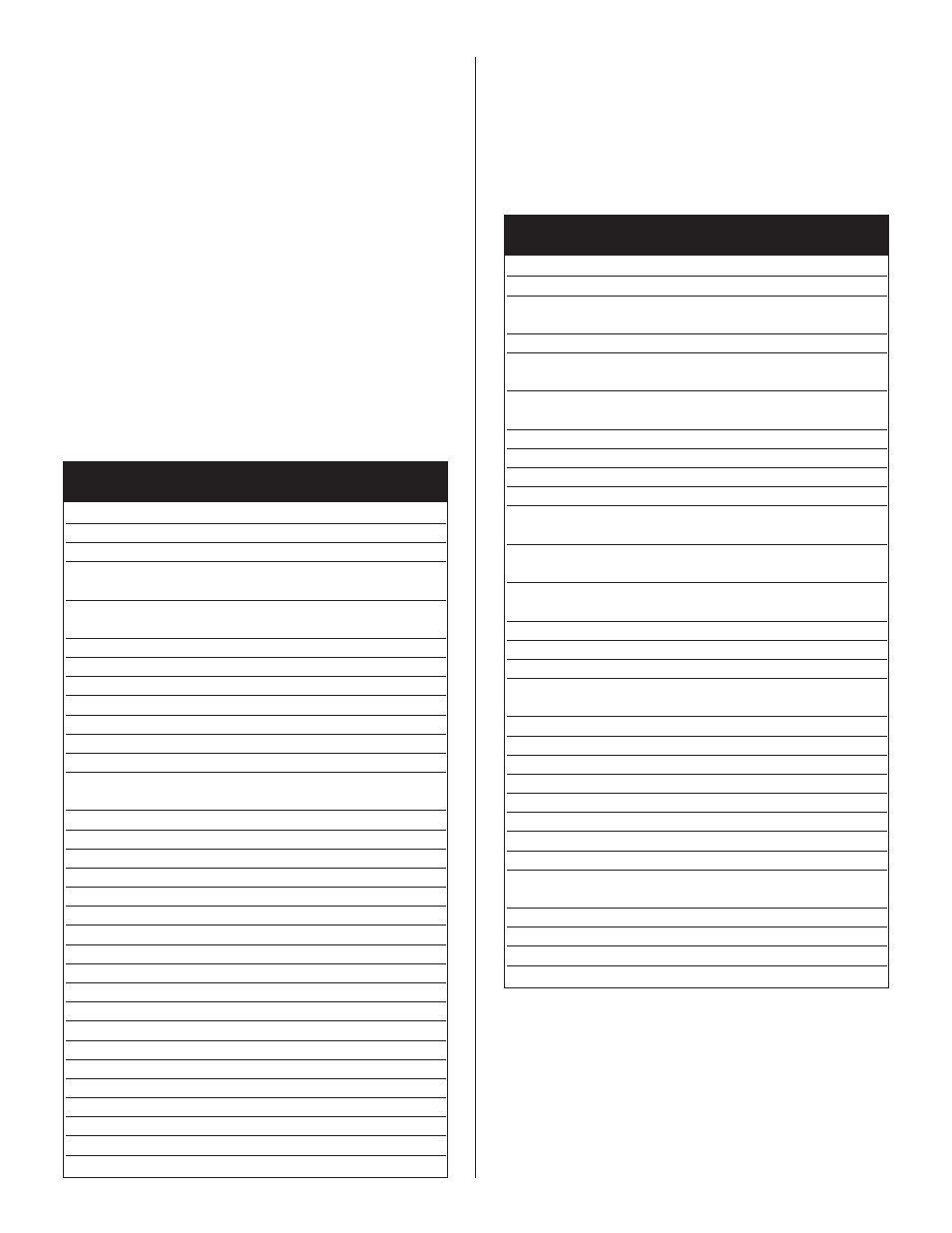

6.2 DDM DRIVE ERROR MESSAGES

If there is a fault, the drive provides specific error

messages. Faults are detected by the drive in two

ways: power-up hardware and run-time faults. A

power-up fault usually requires servicing of the

hardware. A run-time fault can be cleared by

resetting the drive.

The Status display on the front of the servo drive

module indicates faults by flashing the letter ‘

E

’,

followed by additional digits to indicate the error.

The error display repeats until the drive is reset or

powered down.

For example, ‘

E

..

0

..

9

..

E

..

0

..

9

..

E

..

0

..

9

..’ indicates

a Bus Under voltage fault. When an error occurs,

the error code and the service time of the error is

logged into a Fault History record stored in EPROM.

(Refer to Section 6.3)

E....0....1

01

+24 VDC Fuse blown

E....0....2

02

+5 VDC Fuse blown

E....0....3

03

Encoder Power Fuse blown

E....0....4

04

Motor Over temperature,

Thermostat

E....0....5

05

IPM Fault (Over temperature/

Over current/Short Circuit)

E....0....6

06

Channel IM Line Break

E....0....7

07

Channel BM Line Break

E....0....8

08

Channel AM Line Break

E....0....9

09

Bus Under voltage

E....1....0

10

Bus Over voltage

E....1....1

11

Illegal Hall State

E....1....2

12

Unused interrupt-sub processor

E....1....3

13

Unused interrupt - main

processor

E....1....4

14

Reserved

E....1....5

15

Reserved

E....1....6

16

Reserved

E....1....7

17

Excessive Average Current

E....1....8

18

Motor Over speed

E....1....9

19

Excessive Following Error

E....2....0

20

Motor Encoder State Error

E....2....1

21

Auxiliary Encoder State Error

E....2....2

22

Motor Thermal Protection

E....2....3

23

IPM Thermal Protection

E....2....4

24

Velocity Error

E....2....5

25

Commutation Angle Error

E....2....6

26

Reserved

E....2....7

27

Axis Not Homed

E....2....8

28

No Motor Selected

E....2....9

29

Motor Selection not in Table

E....3....0

30

Personality Write Error

E....3....1

31

Service Write Error

E....3....2

32

CPU Communications Error

STATUS

ERROR

FAULT

DISPLAY

CODE

DESCRIPTION

6.3 RUN TIME ERROR CODES

STATUS ERROR

FAULT

DISPLAY

CODE

DESCRIPTION

6.4 POWER-UP ERROR CODES

A power-up error indicates in almost all cases that

the drive should be returned to the factory for

service. In general, any occurrence of a Power-up

error should be treated with extreme caution. It may

indicate the hardware is marginal. (Refer to the

following table for Power-Up Error Codes).

E....5....1

51

Program Memory Boot Block Error

E....5....2

52

Program Memory Main Block Error

E....5....3

53

Uninitialized Personality EPROM

Error

E....5....4

54

Personality EPROM Read Error

E....5....5

55

Personality EPROM Data

Corruption

E....5....6

56

Main Processor Watchdog Error

E....5....7

57

Sub Processor Watchdog Error

E....5....8

58

Main Processor RAM Error

E....5....9

59

Sub Processor RAM Error

E....6....0

60

Uninitialized Service EPROM Error

E....6....1

61

Service EPROM Read Error

E....6....2

62

Service EPROM Data Corruption

Error

E....6....3

63

Main Processor AID Converter

Error

E....6....4

64

Sub Processor A/D Converter

Error

E....6....5

65

ANALOG 1 Output Error

E....6....6

66

Gate Array Error

E....6....7

67

ANALOG2 Output Error

E....6....8

68

Inter-Processor Communication

Error

E....6....9

69

Sub Processor Initialization Error

E....7....0

70

Sub Processor SRAM Error

E....7....1

71

Sub Processor Code Loading Error

E....7....2

72

Sub Processor Start-up Error

E....7....3

73

Sub Processor Checklist Error

E....7....4

74

Personality EPROM Write Error

E....7....5

75

Service EPROM Write Error

E....7....6

76

Software Clock Error

E....7....7

77

Sub Processor Communication

Checklist Error

E....7....8

78

Sine Table Generation Error

E....7....9

79

Personality Data Out of Range

E....8....1

80

Service Data Out of Range

E....8....2

81

Motor Block Checksum Error

7. MAINTENANCE

The Magnum Servo Roll Feed needs very little

maintenance to keep the system operating at its

optimum performance.

•

This precision equipment must be kept as clean

as possible. This is especially important if large

amounts of air suspended oil mists in combination

with “dirty metals” are used. The resulting abrasive