2 set-up mode, 3 auto/manual mode, 4 loading the feed – PA Industries Magnum Servo Roll Feed SRF-M12/18/24/32/36/48 - Installation and Operating Instructions User Manual

Page 7

7

choose between ‘

PRESS-BEFORE-FEED

’ (

PBF

)

and ‘

FEED-BEFORE-PRESS

’ (

FBP

) operating mode.

When ‘

PBF’

mode is selected and the ‘

CYCLE

START

’ button is pressed on the control panel, the

feeder causes the ‘

AUTO

’ and ‘

PERMIT PRESS

’

relays to turn on thus enabling the start of

continuous cycling on the press.

When ‘

FBP

’ is selected and the ‘

CYCLE START

’

button is pressed on the feed control, the material/

strip will be fed forward the programmed pitch

before the press is started. The Operator may verify

that the strip is in position before starting the press.

The Magnum Servo Roll Feed will now follow the

press until it is stopped by the Operator, counter,

emergency stop, or feed error.

5.2 SET-UP MODE

‘

SET-UP MODE

’ is used primarily during the threading

of the strip through the die. This mode allows the

‘

JOG-TO-FEED

’

Length operations to be performed.

While in ‘

SET-UP MODE’

, the strip may be moved

using the ‘

JOG FORWARD

’ operator button. If

the ‘

JOG FORWARD

’ is stopped before the ‘

FEED

LENGTH’

is reached, then either the ‘

JOG FOR-

WARD

’, or ‘

JOG REVERSE

’ operator buttons will

work. The ‘

JOG REVERSE

’ will not allow the

strip to go backwards beyond the initial ‘

FEED

LENGTH’

starting point. The ‘

JOG FORWARD

’

operator button will function until the end of the

‘

FEED LENGTH’

is reached.

During ‘

SET-UP MODE

’, the bottom line on the

display will show ‘

WAITING FOR JOG

’. When the

‘

FEED LENGTH

’ is reached, the jog buttons become

in active and the message on the display will show

‘

WAITING FOR PRESS

’. The jog buttons will not

become active again until after the press has made a

cycle

.

5.3 AUTO/MANUAL MODE

‘

AUTO MODE

’ is used for production running of

the Edge Servo Roll Feed. When ‘

AUTO

’ is selected

via the 2-position selector switch, the control is put

into ‘

MANUAL MODE

’ until the ‘

CYCLE START

’

button is pressed. During manual mode, the feeder

may be jogged infinitely in either direction. After

the ‘

CYCLE START

’ button is pushed, the jog

buttons are inactive, and the feeding of the strip

follows the cam signals from the press. During

‘

AUTO MODE

’, the control keeps check on

synchronization of the feeder and press. If the

Feeder does not complete the index within the feed

cam window, the message ‘

SYNC FAULT

’ displays.

The Magnum Servo Roll Feed has (2) modes of

automatic cycling. The feeder can operate with

‘

SINGLE STROKE

’ or ‘

CONTINUOUS PRESS

MODE

’. The mode is selected through an input to the

feed controller. The press single stroke/continuous

mode switch should be interfaced to this input for

proper operation. During ‘

SINGLE STROKE

’

mode operation, the ‘

PERMIT PRESS

’ output relay

is activated upon the completion of each feed index.

The ‘

PERMIT PRESS OUTPUT RELAY

’ remains

active until the continue cam signal turns on. The

‘

PERMIT PRESS OUTPUT RELAY

’ may be used

to signal the press when to initiate the single stroke

cycle. The automatic cycling of the press and feeder

will continue until the batch is completed, or the

cycle is stopped by the operator, or an error occurs.

During ‘

CONTINUOUS PRESS MODE

’, the

‘

PERMIT PRESS OUTPUT RELAY

’ turns on at the

beginning of the indexing. The ‘

PERMIT PRESS

RELAY

’ remains active until the automatic cycling

is stopped by either ‘

CYCLE STOP

’, ‘

BATCH

COMPLETE

’, ‘

SYNC FAULT

’, or any other drive

related error. Under ‘

CYCLE STOP

’ or ‘

BATCH

COMPLETE

’ stopping, the output will turn off at

the beginning of the ‘

FEED CAM SIGNAL

’. This

should allow the press to stop near the top of the

stroke. Under ‘

SYNC FAULT

’ or other drive fault

conditions, the ‘

PERMIT PRESS RELAY

’ will turn

off immediately upon detection of the error.

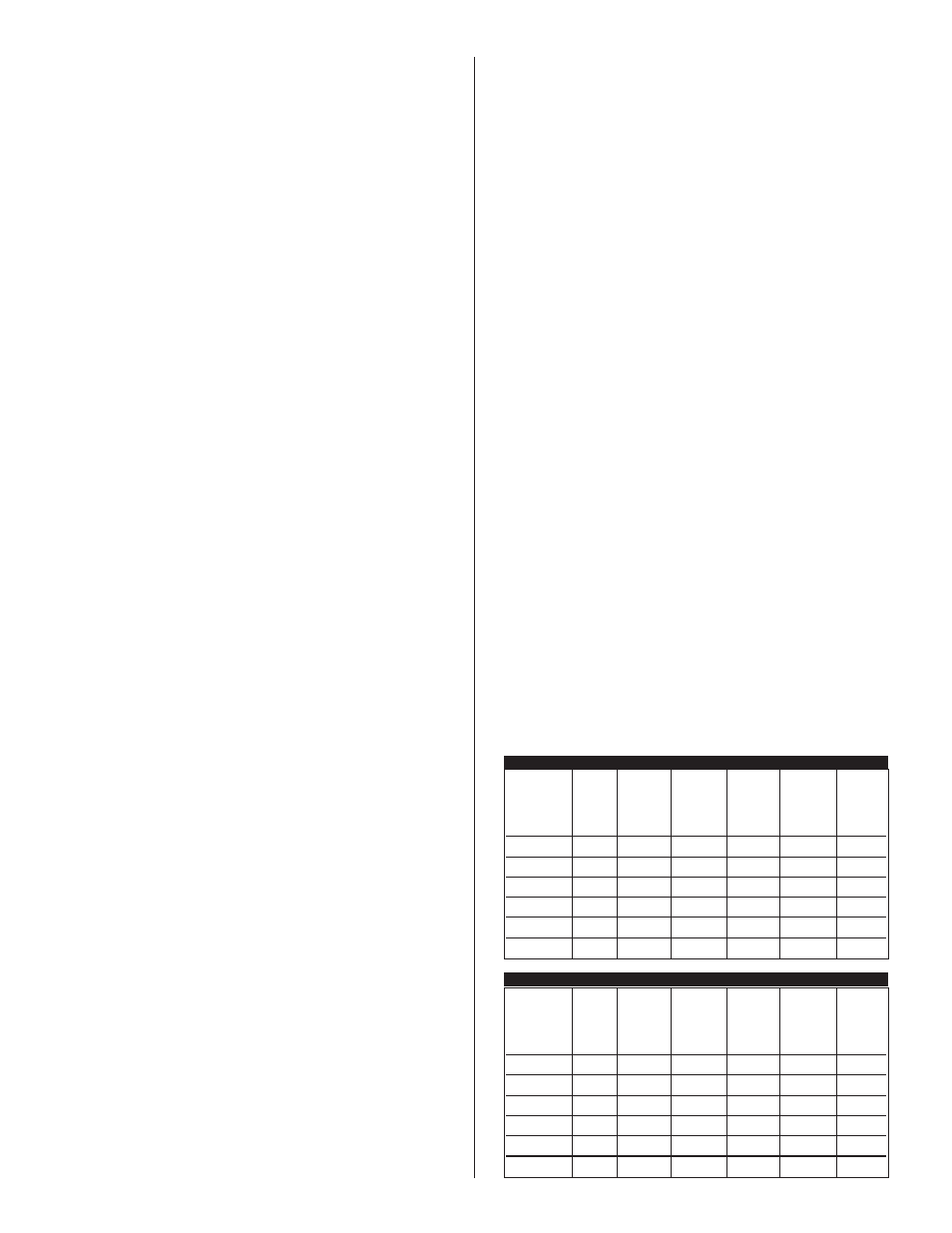

5.4 LOADING THE FEED

The material thickness and width table below defines

the maximum stock thickness at full width allowed.

It also defines the maximum material speed and

cycles per minute (CPM). Do not try to operate the

feeder with material thicker than it was deigned to

feed. READ THIS TABLE BEFORE LOADING

ANY MATERIAL INTO THE FEEDER.

MILLIMETERS

Max.

Max.

Stock

Cross

Max.

Max.

Max.

Thick.

Section Material

Max.

Stock

Stock

At Full

Area

Speed

Feed

Model

Width

Thick.

Width

Sq. In.

Ft./Min.

C.P.M.

SRF-M12

12.0

.250

.200

2.4

315

600

SRF-M18

18.0

.250

.187

3.4

315

600

SRF-M24

24.0

.250

.164

4.0

315

600

SRF-M32

32.0

.250

.136

4.3

315

600

SRF-M36

36.0

.250

.125

4.5

315

600

SRF-M48

48.0

.250

.094

4.5

315

600

Max.

Max.

Stock

Cross

Max.

Max.

Max.

Thick.

Section Material

Max.

Stock

Stock

At Full

Area

Speed

Feed

Model

Width

Thick.

Width

Sq. mm

M/Min.

C.P.M.

SRF-M12

305

6.3

5.1

1550

96

600

SRF-M18

457

6.3

4.7

2200

96

600

SRF-M24

610

6.3

4.2

2600

96

600

SRF-M32

813

6.3

3.4

2800

96

600

SRF-M36

914

6.3

3.2

2900

96

600

SRF-M48

1220

6.3

2.4

2900

96

600

INCHES