4 magnum mounting holes, Programming the magnum servo feed system, Push-button has a – PA Industries Magnum Servo Roll Feed SRF-M12/18/24/32/36/48 - Installation and Operating Instructions User Manual

Page 4: Function built into the button. press the, Button to clear the, Button, or jogged in reverse by pressing the

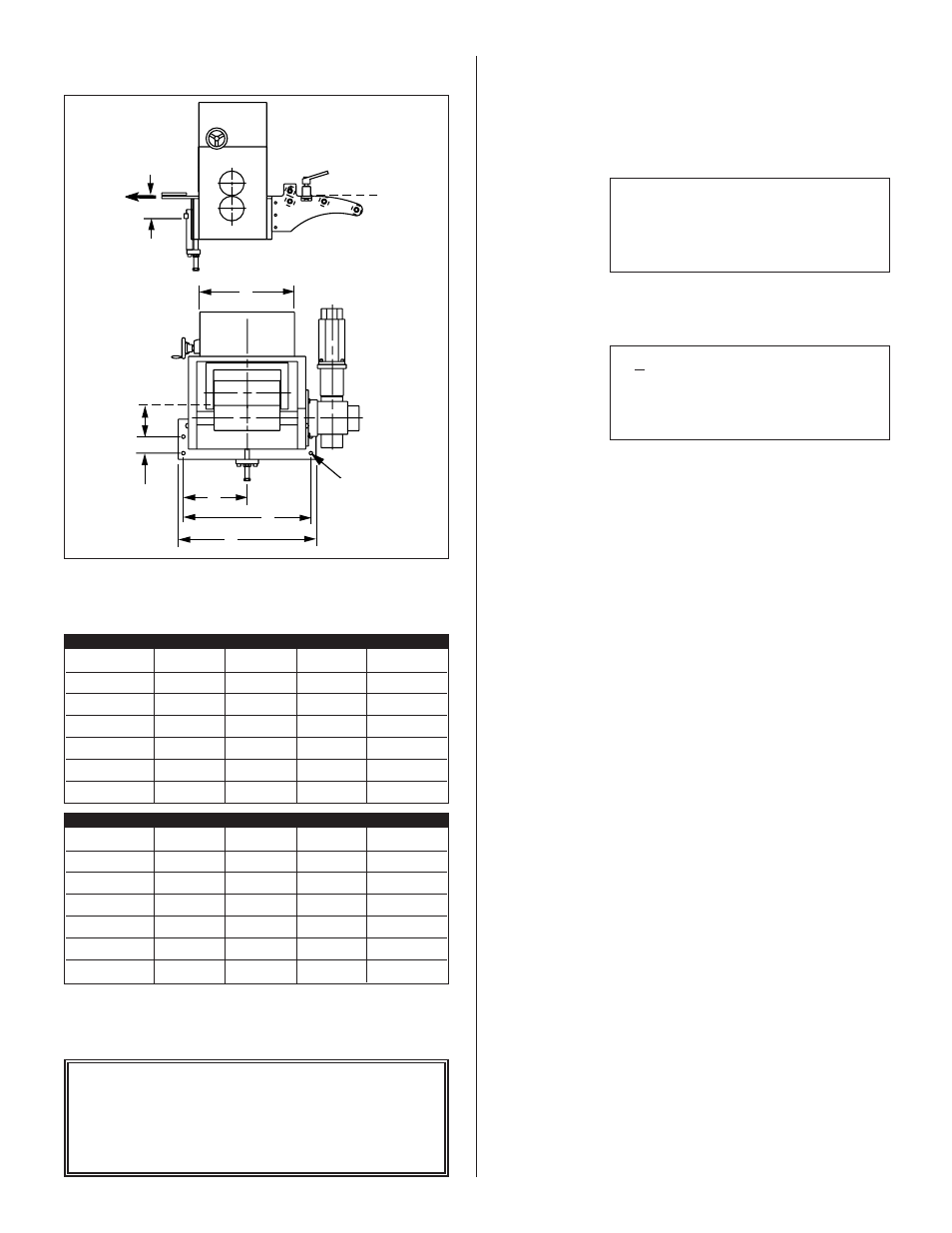

3.4 MAGNUM MOUNTING HOLES

STEP #1:

Turn on the main power disconnect switch. This

applies power to the control power supply. Press the

amber ‘

POWER ON

’ push-button. The button will

illuminate and the data input display will be visible:

☞

STEP #2:

Press any key on the terminal, the display

will show:

☞

STEP #3:

The ‘

POWER ON

’ push-button has a ‘

FAULT

RESET

’ function built into the button. Press the

‘

POWER ON

’ button to clear the ‘

ENCODER

FAULT

’ message at the bottom line of the display.

The feed may now be jogged forward by pressing

the ‘

JOG FORWARD

’ button, or jogged in reverse

by pressing the ‘

JOG REVERSE

’ button.

The Magnum Servo Roll Feed has six viewable

screens. Only the first operator screen (shown

above) will be operator editable/programmable.

This screen displays the length, count, and speed

parameters. These parameters may only be changed

while the program is stopped (indicated by lack of

‘

CYCLE START

’ or set up light). The other

viewable screens are shown on the following page.

These five other screens will be viewable at all times,

but are “locked” out of programming via run/prog

switch located on the electrical panel inside the

electrical enclosure. The factory set parameter

values for the Magnum Servo Roll Feed are printed

on the operator panel below the operator terminal.

These parameters are set from the factory for

average feeding applications and they seldom

require any changes. The five screens and a brief

explanation of the parameters are described below:

• LENGTH:

Distance in inches (or millimeters) of

the feed length. Maximum value of 999.750

inches.

• COUNT:

The number of pieces required to run

in the batch. Maximum value of 999,999 pieces.

MODEL

A

B

C

D

SRF-M12

310

620

670

467

SRF-M18

387

775

825

619

SRF-M24

462

925

975

772

SRF-M32

565

1130

1181

972

SRF-M36

615

1230

1280

1076

SRF-M48

765

1529

1580

1377

4

P/A INDUSTRIES

SERVO ROLL FEED

VERSION 1.00

HIT KEY TO CONT__

LENGTH

00008.000

COUNT

100000

SPEED

0060/SEC

ENCODER FAULT

C

D

4.3” (109mm)

3.1” (80mm)

5.9”

(150mm)

B

A

DRAWING 17573-02

PASS LINE

HEIGHT

ADJUSTMENT

± 2.0”

ш 0.67” (ш17mm)

(4) MOUNTING

HOLES

PASS LINE

MILLIMETERS

MODEL

A

B

C

D

SRF-M12

12.2

24.4

26.4

18.4

SRF-M18

15.3

30.5

32.5

24.4

SRF-M24

18.2

36.4

38.4

30.4

SRF-M32

22.3

44.5

46.5

38.3

SRF-M36

24.2

48.4

50.4

42.4

SRF-M48

30.1

60.2

62.2

54.2

INCHES

MAGNUM MOUNTING HOLES

for drawing 17573-02

Figure 2.

4. PROGRAMMING THE MAGNUM

SERVO FEED SYSTEM

IMPORTANT !

Before turning the system on for the first time,

verify that the main input voltage is correct

(220vac single phase) and inspect all connections

for tightness, shorts, etc.