4 edge mounting holes, Programming the edge servo feed system, Press the amber – PA Industries Edge Servo Roll Feed SRF-100(for Serial Numbers 7610697 and higher) User Manual

Page 4: Button, or jogged in reverse by pressing the

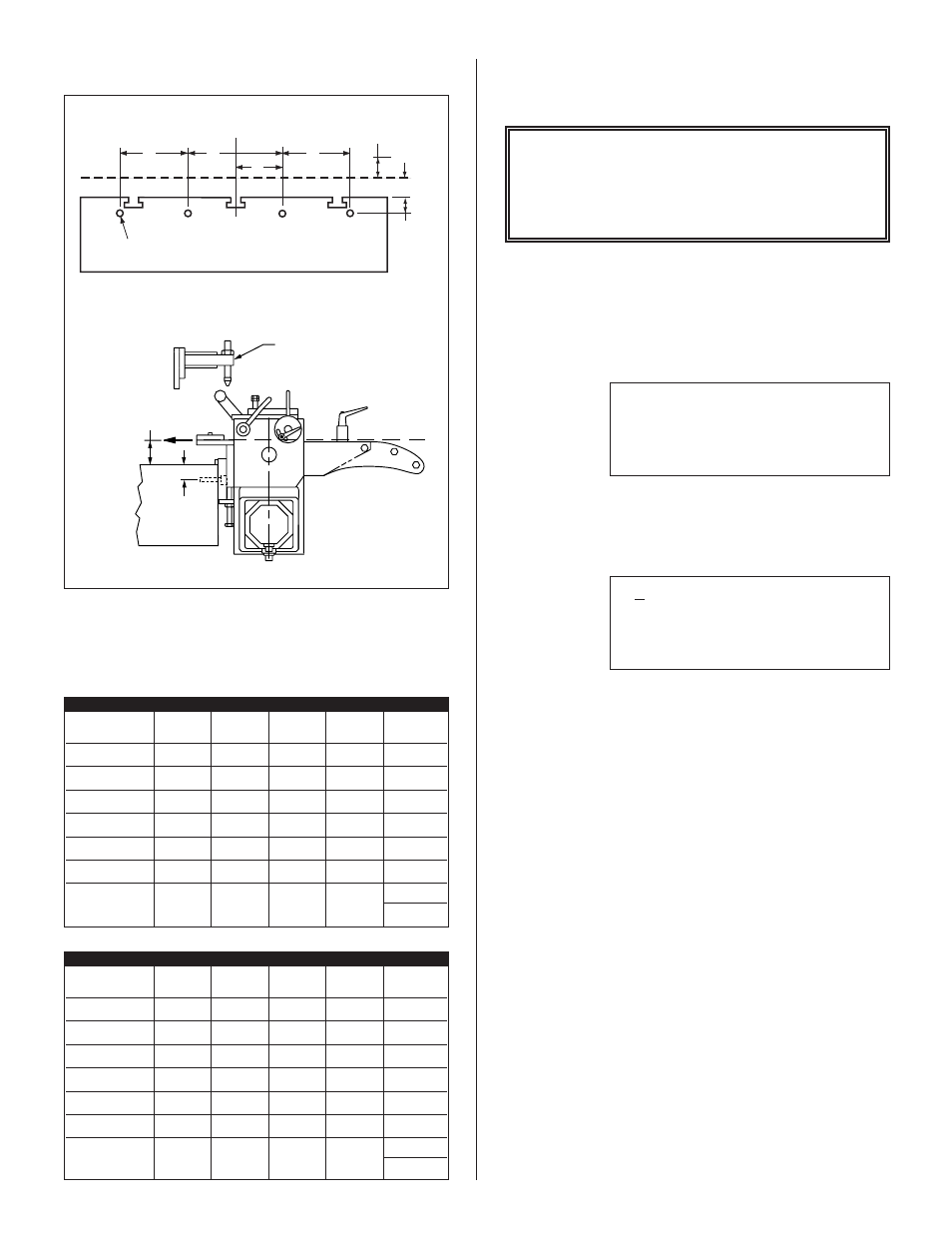

3.4 EDGE MOUNTING HOLES

STEP #1:

Press the amber ‘

POWER ON

’ push-button. The

button will illuminate and the data input display

will be visible:

☞

STEP #2:

Press any key on the terminal, the display will show:

☞

STEP #3:

The ‘

POWER ON

’ push-button has a ‘FAULT

RESET’ function built into the button. The feed

may now be jogged forward by pressing the ‘

JOG

FORWARD

’ button, or jogged in reverse by

pressing the ‘

JOG REVERSE

’ button.

The Edge Servo Roll Feed has six viewable

screens. Only the first operator screen (shown

above) will be operator editable/programmable.

This screen displays the length, count, and speed

parameters. These parameters may only be changed

while the program is stopped (indicated by lack

of ‘

CYCLE START

’ or set up light). The other

viewable screens are shown on the following page.

These five other screens will be viewable at all times,

but are "locked" out of programming via run/prog

switch located on the electrical panel inside the

electrical enclosure. The factory set parameter values

for the Edge Servo Roll Feed are printed on the

operator panel below the operator terminal.

EDGE SRF100-600

SRF-400/

DIMENSION

SRF-100 SRF-125 SRF-200 SRF-300

500/600

A

1.18

1.97

1.97

1.97

1.97

B

1.97

3.15

3.94

3.94

3.94

C

3.94

6.30

7.87

7.87

7.87

D

–

–

–

–

5.91

TAP

M14

M16

M16

M16

M16

E MIN.

2.2

2.4

2.4

2.4

2.4

PASS LINE

+2

+2.4

+2.4

+2.4

+2.4

ADJUSTMENT

-0.0

-0.0

-0.0

-0.0

-0.0

EDGE MOUNTING HOLES

for drawing 17147-03

SRF-400/

DIMENSION

SRF-100 SRF-125 SRF-200 SRF-300

500/600

A

30

50

50

50

50

B

50

80

100

100

100

C

100

160

200

200

200

D

–

–

–

–

150

TAP

M14

M16

M16

M16

M16

E MIN.

55

60

60

60

60

PASS LINE

+50

+60

+60

+60

+60

ADJUSTMENT

-00.0

-00.0

-00.0

-00.0

-00.0

4

CENTER LINE OF RAM

D

C

D

B

E

A

TAP X 1” (25mm) DEEP

BOLSTER

BOLSTER

DRAWING 17147-03

ADJUSTABLE

CAM BAR

TYPICAL MOUNTING ON GAP FRAME PRESS

PASS LINE

ADJUSTMENT

PASS LINE

PASS LINE

E REF

A REF

INCHES

METRIC

Figure 2.

4. PROGRAMMING THE EDGE

SERVO FEED SYSTEM

IMPORTANT !

Before turning the system on for the first time,

verify that the main input voltage is correct

(120 VAC single phase) and inspect all

connections for tightness, shorts, etc.

P/A INDUSTRIES

SERVO ROLL FEED

VERSION 1.00

HIT KEY TO CONT__

LENGTH

00008.000

COUNT

100000

SPEED

0062/SEC

- Edge Servo Roll Feed SRF-125 (for Serial Numbers 7610697 and higher) Edge Servo Roll Feed SRF-200 (for Serial Numbers 7610697 and higher) Edge Servo Roll Feed SRF-300 (for Serial Numbers 7610697 and higher) Edge Servo Roll Feed SRF-400 (for Serial Numbers 7610697 and higher) Edge Servo Roll Feed SRF-500 (for Serial Numbers 7610697 and higher) Edge Servo Roll Feed SRF-600 (for Serial Numbers 7610697 and higher)