PA Industries Edge Servo Roll Feed SRF-100(for Serial Numbers 7610697 and higher) User Manual

Page 10

10

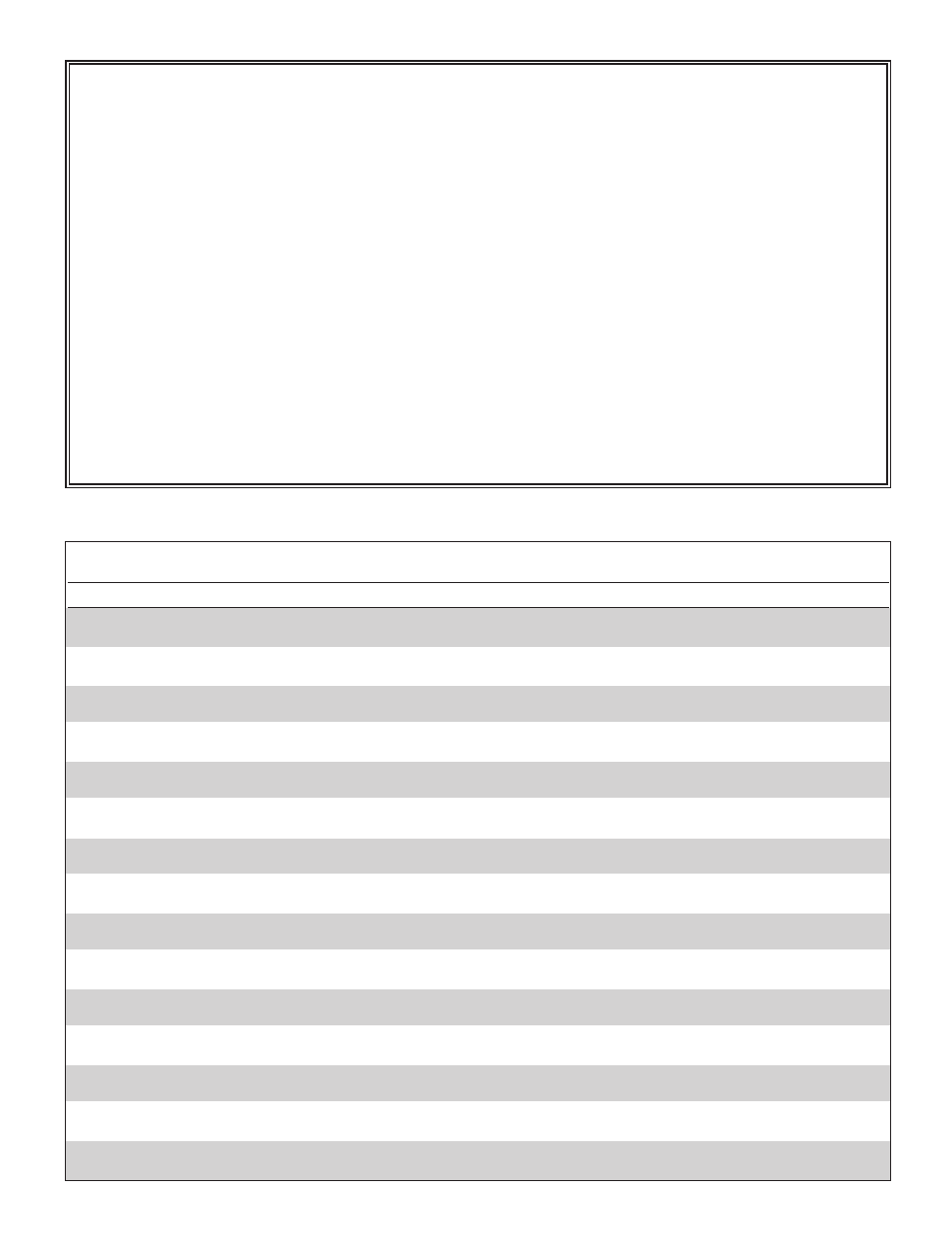

Figure 6. SPEED PERFORMANCE CHART

NOTES ABOUT

"POSSIBLE PROBLEM TOOLING":*

•

A tight die, one that is not square, or has other

tooling problems, will cause significant difficulty

and downtime. Accuracy in feeding is directly

related to how easily the feeder can position the

strip in the die. Binding, bad part ejection, or

sticking parts may cause the material to "jam" in

the die.

•

The Edge Servo Roll Feed will "try" to overcome

the "jam-up" by applying more power to the rolls.

ONE OF FOUR OUTCOMES WILL RESULT:

•

The feed will continue to try to move the strip

(if the rolls do not slip) until the feed advance

cam opens. A Sync Fault Error will occur and

the press will be stopped by the feeder.

•

The feed will apply more power to the rolls,

causing them to slip on the material. This

produces a "short-feed". In reality the feeder

did not "misfeed". The rolls were positioned

properly, the strip did not keep up, causing the

die to close and a miss-hit is produced.

• The feed applies more power to a thin strip,

causing the material to buckle somewhere

between the feed and the die set. The feeder

positioned the strip accurately, it just did not

occur in the die set.

• The feed tries to apply so much power to a heavy

strip in order to move it, that excessive current is

drawn by the servo drive. This results in the

drive shutting down to protect itself and in doing

so stops the press.

NOTE:

The feed detected a problem and emergency-

stopped the press before the die closed. In using

the Edge Servo Roll Feed, you in fact have added

a "die protection" system to your tooling.

* A tooling problem is a problem caused by tooling

and not the Feeder itself.

VELOCITY = 100 In./Sec.

ACCEL = 402 In./Sec

2

FEED CAM WINDOW DEGREES

STROKES PER MINUTE

FEED (In.)

FEED (mm)

FEED TIME (Sec.)

90°

180°

270°

0.25

6.35

0.075

200

400

600

0.50

12.7

0.096

157

313

470

0.75

19.05

0.112

134

269

403

1.00

25.4

0.125

120

240

360

2.00

50.8

0.166

90

180

270

3.00

76.2

0.198

76

151

227

4.00

101.6

0.225

67

133

200

5.00

127

0.249

60

121

181

6.00

152.4

0.270

56

111

167

7.00

177.8

0.290

52

104

155

8.00

203.2

0.308

49

97

146

9.00

228.6

0.325

46

92

138

10.00

254

0.341

44

88

132

11.00

279.4

0.357

42

84

126

12.00

304.8

0.371

40

81

121

14.00

355.6

0.399

38

75

113

16.00

406.4

0.425

35

71

106

18.00

457.2

0.449

33

67

100

20.00

508

0.472

32

64

95

22.00

558.8

0.494

30

61

91

24.00

609.6

0.515

29

58

87

26.00

660.4

0.535

28

56

84

28.00

711.2

0.555

27

54

81

30.00

762

0.575

26

52

78

35.00

889

0.625

24

48

72

40.00

1016

0.675

22

44

67

45.00

1143

0.725

20

41

62

50.00

1270

0.775

19

39

58

55.00

1397

0.825

18

36

55

60.00

1524

0.875

17

34

51

- Edge Servo Roll Feed SRF-125 (for Serial Numbers 7610697 and higher) Edge Servo Roll Feed SRF-200 (for Serial Numbers 7610697 and higher) Edge Servo Roll Feed SRF-300 (for Serial Numbers 7610697 and higher) Edge Servo Roll Feed SRF-400 (for Serial Numbers 7610697 and higher) Edge Servo Roll Feed SRF-500 (for Serial Numbers 7610697 and higher) Edge Servo Roll Feed SRF-600 (for Serial Numbers 7610697 and higher)