1 pro-200 motion control card errors – PA Industries Edge Servo Roll Feed SRF-100(for Serial Numbers 7610697 and higher) User Manual

Page 12

12

Some errors encountered with the Edge Servo Roll Feed may be diagnosed by the motion controller. These

errors are typically displayed on the bottom line of the Operator Terminal Display. These errors are related to

improper motion of the servomotor. These errors are listed below. These errors may be reset by either pushing

‘

POWER ON

’, which has a reset function, or by power-down and power-up.

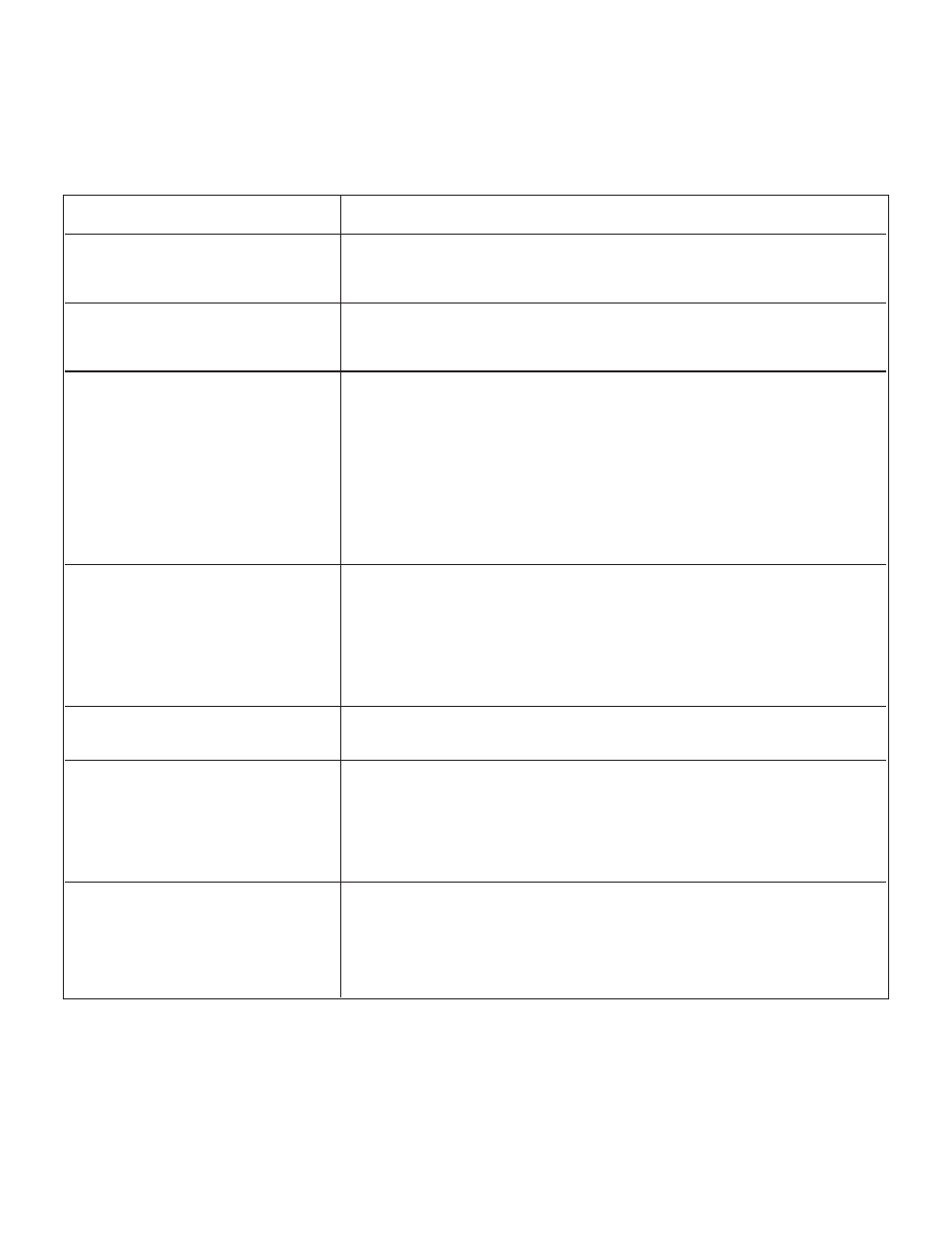

6.1 PRO-200 MOTION CONTROL CARD ERRORS

If the problem you are having does not appear in the above chart, or does appear in the chart, and you have

questions about it, call the P/A Service Department for assistance. Please have your Model Number and Serial

Number ready. However, it is advisable to check the basics before calling to be sure the problem is not

something simple that may have been overlooked.

The servo drive module has built in diagnostics in the form of LED Indicators. See the following pages for more

detailed information.

SYMPTOM

REMEDY

Encoder Feedback Error or

• Simultaneous transitions on the ‘A’ and ‘B’ channels of the encoder were

Encoder Fault

detected or one of the encoder signals is missing (possible broken wire).

Check Pilot Release settings for accuracy. Check Cabling.

Amplifier Fault Detected

• The System Status Output from the Servo Amplifier went ‘OFF’, indicating

a problem with the Servo Amplifier. Try to reset fault by pressing

‘POWER ON’. Check Servo Amplifier for faults.

Excessive Follower Error

• The follower error has exceeded the programmed maximum Follower

Error Limit (FEL) for the Programmed Follower Error time (FET).

• Check for loose or damaged encoder cable or motor cable.

• Check parameters for FEL and FET. Raise the values to see if error

diminishes.

• Check for excessively -speed setting. (I.e. above 72 Inches/Second)

• Check for binding in the tool. Check for mechanical binding or overload

caused by material or tooling.

Nonvolatile RAM Checksum Error

• The process found a problem with the checksum of the parameters.

The most likely cause of this will be a power failure while entering new

data or electrical noise at power up/down.

• Loss of power while entering the parameters

• Electrical noise addection the control. Check all solenoids and relays for

surge suppression.

Parameter Error

• A parameter was entered improperly. Review all parameters per legend

panel. Correct any deviant parameters.

Watchdog Time-out Fault

• Check that the watchdog timer triggered, indicating that the

microprocessor was not operating properly or momentary power failure.

Frequently caused by ‘POWER OFF’ immediately followed by ‘POWER ON’

without waiting for ‘POWER ON’.

• Wait 10 seconds after power down before power on.

Limit Switch Hit

• Check if the ‘FORWARD LIMIT’ or ‘REVERSE LIMIT’ switch has

been activated.

• Check Limit Switch for end of material at inlet of feeder.

• Check the inputs for 24 DC on the control.

- Edge Servo Roll Feed SRF-125 (for Serial Numbers 7610697 and higher) Edge Servo Roll Feed SRF-200 (for Serial Numbers 7610697 and higher) Edge Servo Roll Feed SRF-300 (for Serial Numbers 7610697 and higher) Edge Servo Roll Feed SRF-400 (for Serial Numbers 7610697 and higher) Edge Servo Roll Feed SRF-500 (for Serial Numbers 7610697 and higher) Edge Servo Roll Feed SRF-600 (for Serial Numbers 7610697 and higher)