Roll feed parts list & diagram – PA Industries Edge Servo Roll Feed SRF-100(for Serial Numbers 7610697 and higher) User Manual

Page 14

14

• The main drive belt should be checked periodically

for tightness. It can be adjusted by loosening the

two fasteners on the motor adjuster plate, applying

downward pressure on the motor adapter plate,

and retightening. ERRATIC MOTOR

BEHAVIOR WILL BE EXPERIENCED IF THE

DRIVE BELT IS LOOSE!

• All fasteners should be checked for tightness at

regular intervals. The electrical system also requires

very little maintenance. Keep the enclosure clean

and replace any burned indicator bulbs. Do not

expose the electrical enclosure to constant high

temperatures. Possible system failure could result.

• The Feeder’s electrical enclosure door is sealed

to prevent oil and contaminants from entering

inside. However, small gaps can be found around

some sealing surfaces and faceplates. It is a

good idea, therefore, to keep the console free of

stamping oils and fluids, which could "seep into"

the enclosure. Most often these oils are

carried by the operator’s hands or by air mist

lubrication etc.

• All of the above guidelines should be added to

your existing pressroom Preventive Maintenance

(PM) Program.

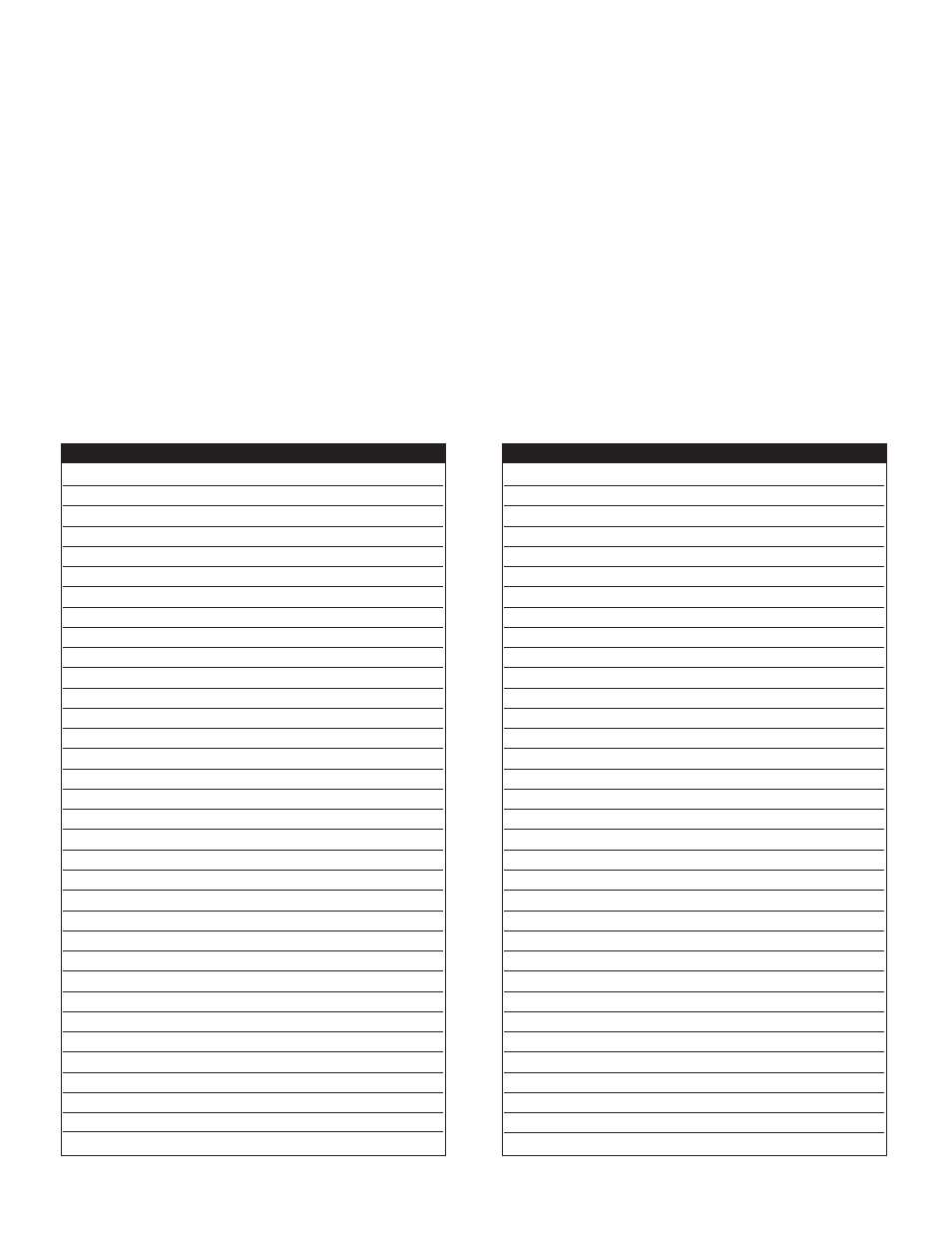

8. ROLL FEED PARTS LIST & DIAGRAM

1

1

BEARING HOUSING - LEFT SIDE PLATE

2

1

BEARING HOUSING - RIGHT SIDE PLATE

3

1

PLATE- CASCADE MTG.

4

1

PLATE - FEED MTG.

5

1

PLATE - EXIT

6

1

PLATE - MATERIAL HOLD DOWN

7

1

BRACKET - UPPER ROLL, LEFT

8

1

BRACKET - UPPER ROLL, RIGHT

9

1

PLATE - UPPER ROLL

10

1

GUARD - ENTRY

11

1

ROLL - LOWER

12

2

DUST SHIELD - LOWER

13

1

SPACER - LOWER

14

2

BEARING - LOWER

15

1

GEAR - LOWER

16

1

ROLL - UPPER

17

2

DUST SHIELD - UPPER

18

2

RETAINING RING

19

2

BEARING - UPPER

20

1

GEAR - UPPER

21

1

SHAFT - THICKNESS ADJUSTMENT

22

1

LEVER - THICKNESS ADJUSTMENT

23

1

CAM ECCENTRIC BUSHING

24

1

BUSHING - TAPER LOCK - INNER

25

1

BUSHING - TAPER LOCK - OUTER

26

1

SHAFT - ROLL RELEASE

27

2

BEARING, NEEDLE

28

2

WEAR PAD

29

1

RELEASE LEVER - MANUAL

30

1

RELEASE LEVER - MECHANICAL

31

1

BEARING - ROLL RELEASE

32

1

SPACER - RELEASE BEARING

33

2

RETAINER, SPRING ROD

34

2

ROD, ROLL TENSION

ITEM

QTY

DESCRIPTION

35

2

SPRING, ROLL TENSION

36

1

SET SCREW M6 X 16

37

2

BRACKET - CASCADE

38

1

BLOCK - CASCADE MTG., LEFT

39

1

BLOCK - CASCADE MTG., RIGHT

40

1

PLATE - ENTRY

41

2

BAR - GUIDE ROLLER

42

2

CLAMP - GUIDE BAR

43

2

GUIDE ROLLER

44

4

SPACER - GUIDE ROLLER

45

2

NUT - T SLOT

46

3

ROLL - CASCADE, ENTRY

47

3

SHAFT - ROLL

48

10

BEARING - GUIDE & ENTRY ROLL

49

1

TRANSITION PLATE

50

1

ADJUSTMENT TAB

51

1

SCREW - HEX HD

52

1

NUT - HEX, JAM

53

1

KEY 22mm x 5mm x 110mm

54

2

KEY 22mm x 12mm x 40mm

55

1

STRIKER - RELEASE ACTUATOR

56

1

ARM - ADJUST

57

1

ARM - FIXED

58

1

BLOCK - MOUNTING

59

1

BRACKET - MOUNTING

60

1

NUT, STRIKER ADJUST

63

1

KEY 7mm SQ x 35mm

64

1

KEY 5mm SQ x 15mm

65

4

GREASE FITTING

67

4

NUT, M14, ROLL TENSION

68

1

COVER, FEED ROLLS – SRF-100

69

2

HANDLE, WIDTH GUIDE ADJUSTMENT

70

1

HANDLE, THICKNESS ADJUSTMENT

71

6

NUT, HEX

ITEM

QTY

DESCRIPTION

- Edge Servo Roll Feed SRF-125 (for Serial Numbers 7610697 and higher) Edge Servo Roll Feed SRF-200 (for Serial Numbers 7610697 and higher) Edge Servo Roll Feed SRF-300 (for Serial Numbers 7610697 and higher) Edge Servo Roll Feed SRF-400 (for Serial Numbers 7610697 and higher) Edge Servo Roll Feed SRF-500 (for Serial Numbers 7610697 and higher) Edge Servo Roll Feed SRF-600 (for Serial Numbers 7610697 and higher)