PA Industries Edge Servo Roll Feed SRF-100(for Serial Numbers 7610697 and higher) User Manual

Page 2

1.

INTRODUCTION ................................... 2

2.

HOW AN EDGE

SERVO FEED OPERATES .................... 2

2.1

MECHANICAL ASSEMBLY .............. 2

2.2

ELECTRICAL CONTROL

ENCLOSURE ASSEMBLY ............... 2

3.

INSTALLING YOUR EDGE

SERVO FEED ........................................ 3

3.1

MECHANICAL INSTALLATION ........ 3

3.2

ELECTRICAL INSTALLATION .......... 3

3.3

ELECTRICAL CONNECTIONS ........ 3

3.4

EDGE MOUNTING HOLES .............. 4

4.

PROGRAMMING THE EDGE SERVO

FEED SYSTEM ...................................... 4

4.1

PROGRAM A NEW FEED

LENGTH, COUNT, SPEED .............. 6

4.2

PROGRAM A NEW BATCH

COUNT ............................................. 6

4.3

PROGRAM A NEW SPEED

FOR THE FEED ............................... 6

5.

OPERATING THE FEED ....................... 7

5.1

PRIORITY MODE ............................ 7

5.2

SET-UP MODE ................................. 7

5.3

AUTO/MANUAL MODE .................... 7

5.4

LOADING THE FEED ....................... 8

5.5

RUNNING THE FEED ....................... 8

6.

TROUBLESHOOTING GUIDE ..............11

6.1

PRO-200 MOTION

CONTROL CARD ERRORS ............12

6.2

DRIVE MODULE DIAGNOSTICS ....13

7.

MAINTENANCE ....................................13

8.

ROLL FEED PARTS LIST

AND DIAGRAM .................................... 14

WARNING .................................................... 16

SAFETY PROGRAM ....................................16

WARRANTY ................................................. 16

1. INTRODUCTION

The P/A Industries Edge Servo Roll Feed is

a state of the art AC Servo feed which eases operator

adjustments to feed pitch, feeder speed, and feed

acceleration. These operator adjustments are entered

into the control memory by key pad input. With the

use of positional limit switches, the press signals the

feeder when to begin moving the strip, when the

feed pitch must be completed, when the press has

completed its down stroke, and with optional pneu-

matic release, when to open the rolls for piloting.

The mechanical simplicity, accuracy, and ease of use

of the Edge Servo Roll Feed should help to improve

your quality and production for years to come.

2. HOW AN EDGE SERVO

FEED OPERATES

The Edge Servo Roll Feed consists of:

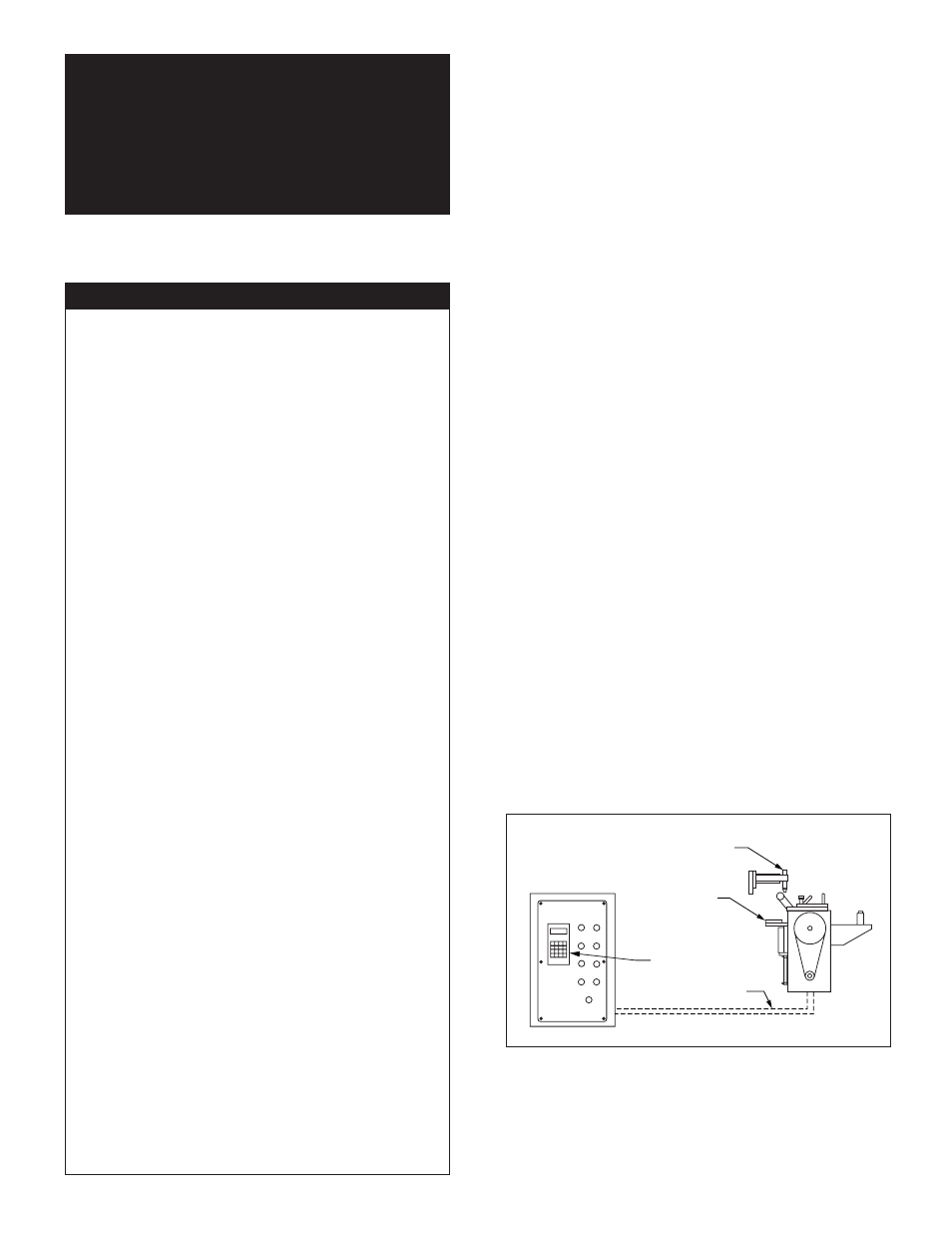

2.1 MECHANICAL ASSEMBLY

(Refer to Figure 1)

1) Adjustment/Mounting bracket

2) Feeder

3) Motor

4) Mechanical pilot release actuator

2.2 ELECTRICAL CONTROL

ENCLOSURE ASSEMBLY

(Refer to Figure 1)

1) Control switches/buttons

2) Power supply, 120 VAC (for controls)

3) Motor/Axis control module

(inside electrical enclosure)

4) Data entry terminal

5) Cabling

The introduction of servomotor technology to the

press roll feed has pushed the limits of accuracy,

adjustability, and performance to levels previously

unattainable.

2

CONTROL

ENCLOSURE

DATA

TERMINAL

CABLES

DRAWING 17415

ADJUSTABLE

MOUNTING

BRACKET

MECHANICAL PILOT

RELEASE ACTUATOR

DESCRIPTION PAGE

TABLE OF CONTENTS

Figure 1.

RECEIVING INSPECTION

Before removing unit from its packaging, check for

visual damage, especially if crate, skid, or carton has

been damaged in transit. Any damage caused by

shipping should be immediately reported to the

carrier. If unit appears in satisfactory condition,

remove all packing and wipe rust preventive from

rollers with mild solvent.

- Edge Servo Roll Feed SRF-125 (for Serial Numbers 7610697 and higher) Edge Servo Roll Feed SRF-200 (for Serial Numbers 7610697 and higher) Edge Servo Roll Feed SRF-300 (for Serial Numbers 7610697 and higher) Edge Servo Roll Feed SRF-400 (for Serial Numbers 7610697 and higher) Edge Servo Roll Feed SRF-500 (for Serial Numbers 7610697 and higher) Edge Servo Roll Feed SRF-600 (for Serial Numbers 7610697 and higher)