Rtl & rtl-fcb series, Chart 6 – DE-STA-CO Ferguson Rite-Torq Torque Limiters (Overload Clutches) Type RT, RTM, RTL, RTL-FCB User Manual

Page 14

14

RTL & RTL-FCB Series

NOTE: Trip torque should be less than the maximum the machine can absorb without risk

but great enough to prevent undesirable nuisance tripping due to inertia or starting loads.

Ideally, trip torque should be approximately 40% higher than the operating torque of the

machine.

WARNING: IF THE DRIVE HAS A BRAKE MOTOR, THE TRIP SETTING MUST BE WELL

ABOVE THE BRAKE TORQUE; OTHERWISE WITH A HIGH INERTIA DRIVE, THE CLUTCH MAY

TRIP WHEN THE BRAKE IS APPLIED, ALLOWING THE MACHINE TO RUN UNCONTROLLED

BY THE BRAKE.

Number

Approximate Static Trip Torque

(IN-LBS)

Of

Turns

RTL-5

RTL-50

RTL-60

RTL-120

0

500

2000

6000

12000

½

450

1900

5500

11500

1

375

1700

5000

10500

1 ½

300

1500

4500

9500

2

225

1300

4000

9000

2 ½

150

1200

3500

8000

3

100

1000

3000

7000

3 ½

-----

800

2500

6000

4

-----

600

2000

5000

4 ½

-----

500

1700

4500

5

-----

400

1400

4000

5 ½

-----

-----

1200

3500

6

-----

-----

-----

3000

6 ½

-----

-----

-----

2400

CHART 6

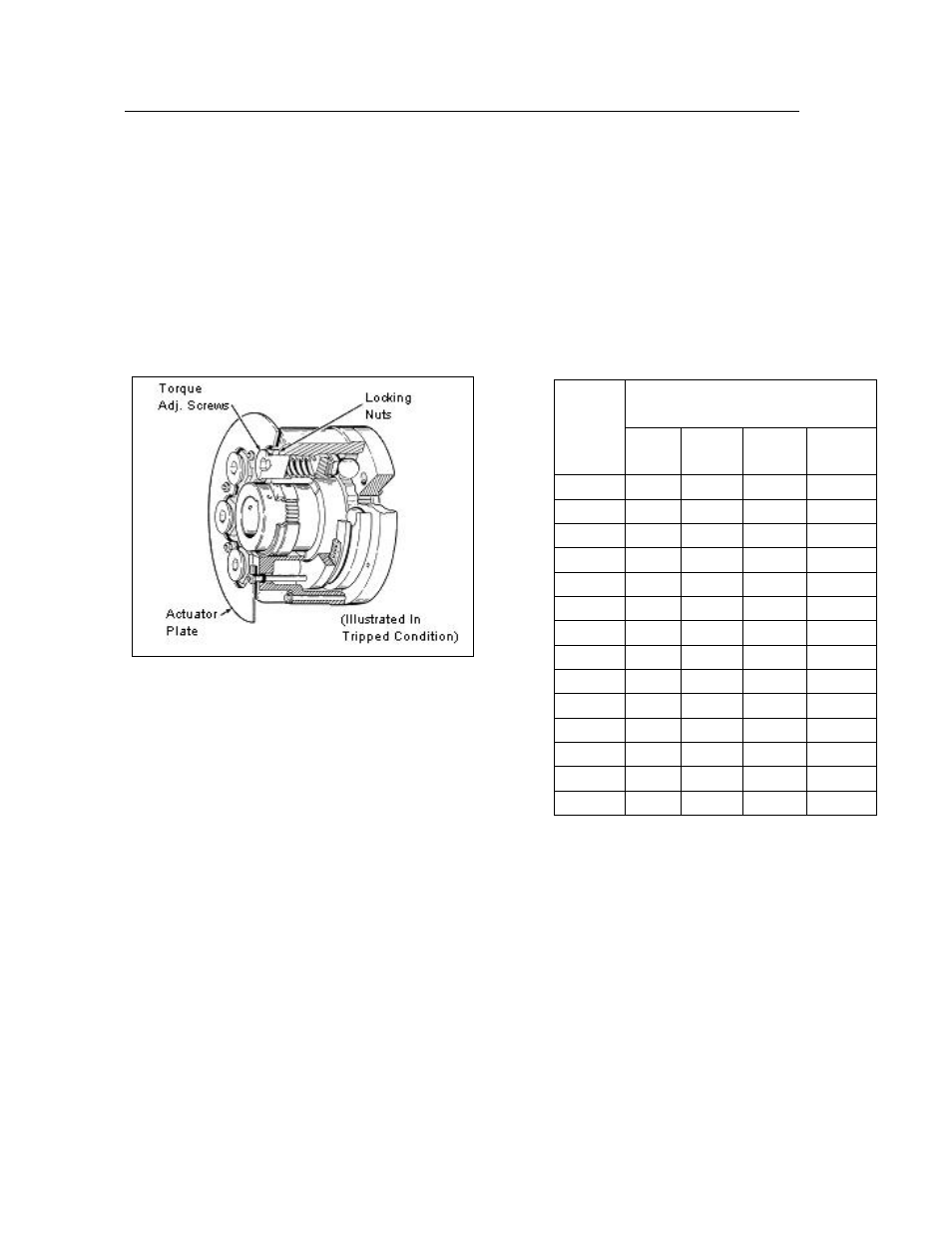

1. Adjust trip torque (Figure 8) by loosening locknuts.

2. Tighten torque adjusting screws all the way down.

3. Back torque adjusting screws off the number of turns in Chart 6 to the desired torque range.

4. Tighten locking nuts to maintain setting.

5. Check the distance between torque adjusting screw heads and locking nuts. All must be the same to insure even spring

compression.

NOTE: All Industrial Motion Control detent clutches are reset by:

1. Turning the power off.

2. Clear jam condition.

3. Rotate machine manually or slow jog until clutch snaps back in the home position. Torque limiter

will re-engage from either direction.

FIGURE 8