Metric installation specifications, Chart 4 – DE-STA-CO Ferguson Rite-Torq Torque Limiters (Overload Clutches) Type RT, RTM, RTL, RTL-FCB User Manual

Page 11

11

METRIC INSTALLATION SPECIFICATIONS

Trip Torque

(Nm)

Max.

Actuator

Plate

Sprocket Mounting

Max.

Model

MIN.

MAX

RPM

Travel

Thread*

B.C.

NO.

Pilot Dia.

Bore

5

11,3

56,5

1800

1,85 mm

N/A

95,3 mm

4

63,5 mm

31,8 mm

20

58,4

113,0

1200

2,34 mm

N/A

123,8 mm

6

85,7 mm

44,5 mm

60

175,2

875,9

900

2,79 mm

N/A

152,4 mm

6

101,6 mm

57,2 mm

120

350,4

1751,8

600

3,71 mm

N/A

177,8 mm

6

120,7 mm

69,9 mm

CHART 4

NOTE: RTL & RTL FCB Torque Limiters are built in English dimensions unless otherwise noted. Metric

measures above are approximate conversion from English only.

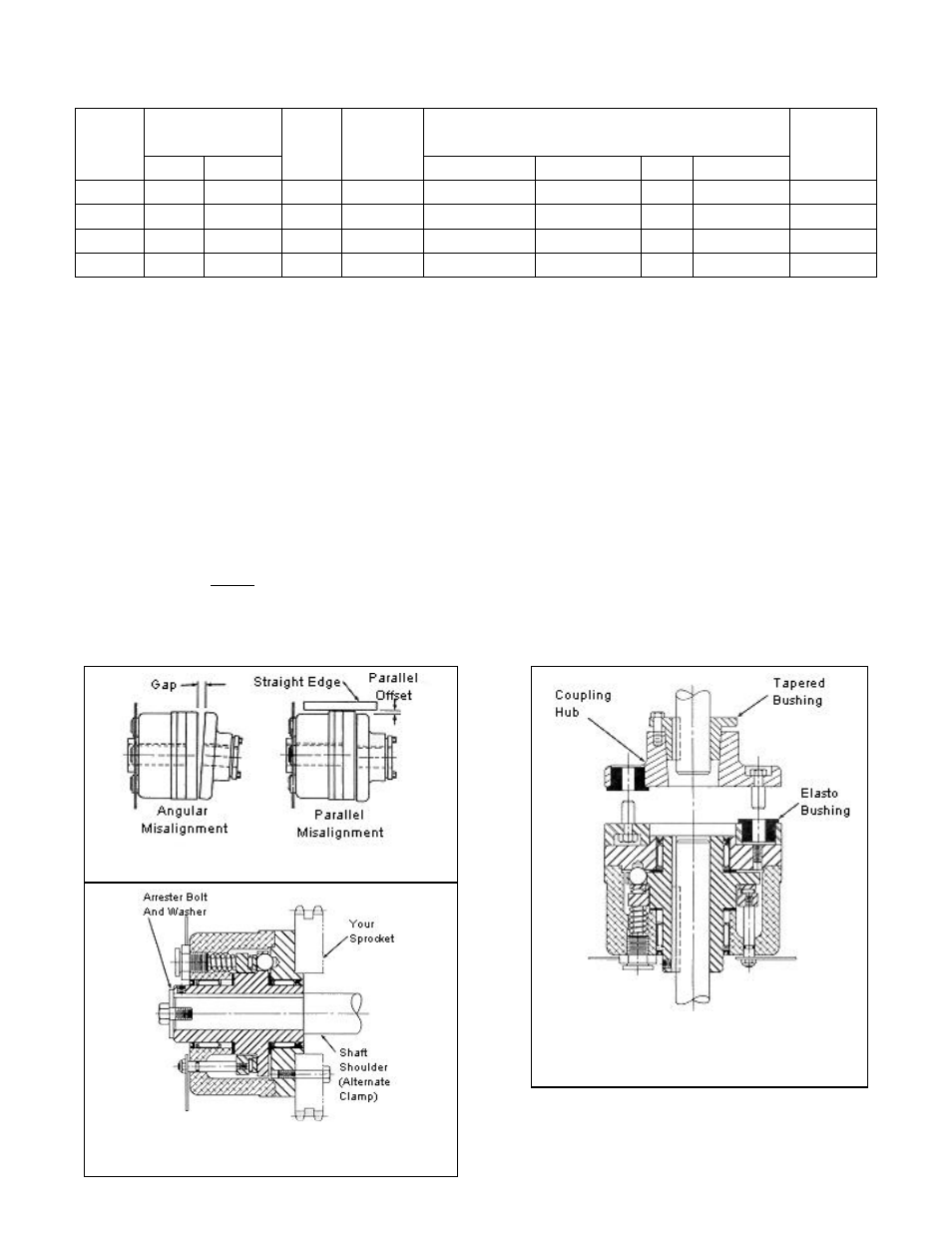

10. Slide torque limiter onto shaft of reducer, etc. with sprocket side as close as possible to the

bearing of the unit without rubbing. Secure torque limiter in place by tightening the two set

screws provided. Again, the use of Loctite® is recommended. Additional clamping can be

provided by using an arrestor bolt and washer to hold the unit against a shaft shoulder or

clamping collar (see Figure 5).

NOTE: Steps 11-12 apply to both RTL and RTL-FCB clutches.

11. Mount and adjust limit switch into proper position with switch trip plate.

12. Turn on power and inspect.

FIGURE 3 FIGURE 4

FIGURE 5

FIGURE 6